INTERVIEW: Continental Industries

Pile Buck’s interview with Continental, one of the world’s leading providers of conveyor belt systems, industrial hoses, drive belts, and safety systems for the construction sector.

PB: Before we dive in, can you explain how Continental is organized?

CT: Well, Continental is comprised of several group sectors. Since your readers are interested in products and services for the construction industry, we’ll focus on the ContiTech group sector.

PB: The ContiTech group sector is divided into six business areas, yes?

CT: That’s right. Each business area – Advanced Dynamic Solutions, Conveying Solutions, Industrial Fluid Solutions, Mobile Fluid Solutions, Power Transmission Group, and Surface Solutions – operates as a decentralized unit.

PB: Pile Buck readers, as you say, are interested in construction-related products and services. But first we want to know how the horse became part of the Continental logo.

CT: In 1875 – four years after Continental was founded – a horse was used in the brochure advertising the “Hartmann’s Patent Hufbuffer.” An early ContiTech innovation, a hoof buffer was placed between the horseshoe and the horse’s hoof. The padding allowed the horse to move more naturally and reduced injuries. Over time the horse evolved into our trademark. It was redesigned and became less about hooves and more about forward-thinking innovation. Thus Continental’s tag line, “The Future in Motion.”

PB: You’ve gone well beyond horseshoes in the last 150 years. Tell us about the Big Bubble Curtain Hose.

CT: Offshore construction work, such as the anchoring of foundations for wind turbines, creates an enormous amount of underwater noise. Sound intensity can reach 180 dB at source during pile driving – equivalent of a rocket launch. The Big Bubble Curtain Hose reduces this noise level.

PB: Construction work is loud. Can’t employees just use ear protection?

CT: The employees can – but porpoises and other marine creatures can’t. Several countries have regulations to protect these sound-sensitive mammals. For example, A maximum noise level of 160 dB applies in German waters at a distance of 750 meters from any construction site.

PB: How does the Big Bubble Curtain Hose reduce noise level?

CT: A perforated hose is laid around the construction site that creates a curtain of air bubbles generated by compressed air. This changes the density of the water, which causes the sound waves to break up — reducing construction noise.

PB: The reduction is only 20 dB. Does it really make that much of a difference?

CT: An increase in sound level of 6 dB is perceived as a doubling of the volume. Likewise, a measure that reduces the volume by 6 decibels halves the perceived noise, which is why a noise reduction of 18 dB can be quantified as a 95% decrease.

CT: Previously, installation companies fitted the hoses with additional weights to anchor them to the sea floor or positioned them on piping systems. This made installation on the sea floor and transport back to the surface of the water complicated. The Big Bubble Curtain Hose has a heavyweight wire wrapped around it. This lends the hose the right degree of balance at the required depth and without the need for compressed air to keep it buoyant.

PB: ContiTech sells several products to increase comfort and safety for equipment operators.

CT: We have several products including display and instruments solutions, infotainment systems, vehicle access control, and telematics. For example, the MultiViu® Professional 12 is an instrument cluster with a 12.3-inch color display. You can play videos on it, it’s fully programmable, and fits seamlessly into any front frame. Oh, and it’s off-the-shelf.

PB: Tell us about Continental’s conveyer belt systems for material handling.

CT: We have several systems. Our textile conveyor belts with fabric reinforcement have been tested in many tough environments over 150 years. A great example of our textile conveyor belts is Texsteel. It is reinforced with aramid synthetic fibers to provide longer belt life under extreme conditions. It has greater rip, tear and impact resistance, and superior load support and durability. Other belt systems include Steelcord, Steep Incline, and Steel Mesh. We have the right conveyer belt system for nearly any industry.

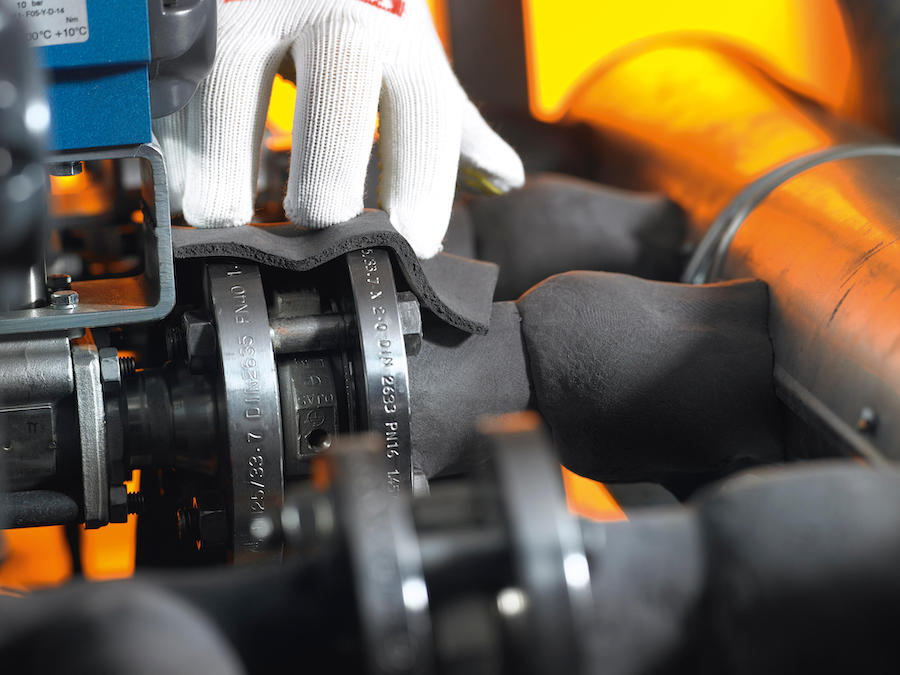

PB: What is Conti® Thermo Protect?

CT: Conti® Thermo Protect (CTP©) is a highly flexible insulation material designed for the thermal insulation and protection of flexible and complex hose and piping systems. It can handle a high-temperature range up to 250°C.

PB: Conti® Thermo Protect comes in different variants?

CT: CTP© with increased insulation performance or CTP©-B with improved fire resistance. Conti® Thermo Protect is available as a ductile variant called Conti® Thermo Protect GUM, with which complex applications can be easily insulated. Conti® Thermo Protect GUM automatically connects after installation on a hot component and then becomes a flexible but rigid rubber molded product.

PB: What are the advantages of Conti® Thermo Protect GUM?

CT: There are several. Energy savings, reduction of CO2 emissions, industrial safety, noise reduction, and vibration damping.

PB: What types of services do you offer the construction industry?

CT: We offer several high-value services, such as belt installation and replacement, conveyor data systems, asset inventory management, and conveyor belt systems for hire. We have so many different tools to improve the construction environment for everyone in the organization. It’s worth contacting us to discuss what services and products would serve you best.

PB: What else do you want our readers to know about Continental?

CT: We believe in a sustainable future – and have committed to a plan for that. You can read more about what we call a “comprehensive sustainability framework” on our website. We are looking at everything from 100% carbon neutrality to 100% emission-free mobility and industries.

Who is Continental Industries?

Continental Industries is a recognized industry leader specializing in pipe joining solutions. They provide a wide range of products for various applications including gas, water, and industrial markets.

What makes Continental Industries stand out in the market?

Continental Industries stands out due to their commitment to quality, innovation, and customer service. Their products are designed to meet stringent standards and they continuously aim to provide solutions that enhance efficiency and reliability in the industry.