INTERVIEW: Chance Foundation Solutions

Pile Buck’s interview with Chance Foundation Solutions, an international leader in earth anchoring offering helical piles used worldwide for many deep foundation applications.

PB: How did Chance Foundations get its start?

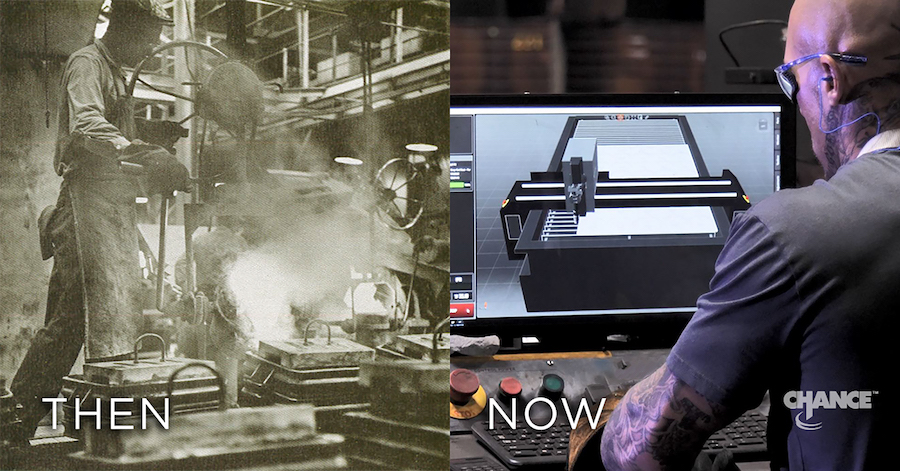

CH: We’ve been doing this for a while. We first started making earth anchors in 1912. At the time, “screw piles” had been in use for about 70 years but had somewhat fallen “out of style” with the advent of heavy machinery and the steam powered pile drivers. Albert Bishop Chance reinvigorated the technology when he patented his “Never Creep” plate anchor. Since then, Chance engineers have spent decades building the helical pile deep foundation industry, providing valuable research that’s used across all helical pile brands today. If you like history, our blog has a story written in 1935 about how it all started.

PB: What is the Chance Universal Adapter?

CH: The Chance Universal Adapter connects a square shaft helical anchor to commonly available thread bars. The Universal Adapter is used with helical tieback anchors as a way to “countersink” the anchor and threadbar adapter with a drive tool behind the tieback wall, thereby increasing efficiency and keeping personnel safely front of the wall. (Read Pile Buck’s article on this product!)

PB: How does it work?

CH: Once the minimum embedment for the tie-back anchor is achieved, the universal adapter is attached to the exposed square bar shaft. Then any commonly available thread bar is slipped into the Universal Adapter and attached with the appropriate load nut. If needed, the installer can then place the drive tool over the thread bar and adapter and continue with the anchor installation until final torque and embedment is achieved. Here’s a quick video.

PB: Let’s talk about some of your helical brackets.

CH: Brackets are an important, yet often overlooked, part of a pile solution used in conjunction with Chance Anchors and Helical Piles. Brackets basically provide the connection between the helical piles and the structure that is being supported. They are used for a wide variety of applications, including new construction, underpinning, concrete slab raising, and follow the same manufacturing and quality control audits that our helical piles do.

PB: What are some differences in the different types of brackets used?

CH: Brackets typically fall into two groups – new construction brackets and underpinning brackets. They both transfer the load of the structure to the pile, so it is important that the right style and the right quality be selected. Don’t worry, we have people who can help with that.

PB: Tell us about your helical piles and anchors.

CH: A helical pile is an extendable deep foundation system with helical bearing plates welded to a central steel shaft. Basically, a load is transferred from the structure via the brackets into the shaft of the pile, which then transfers that load to the soil through the helix bearing plates at the pile tip. We’ve tested our piles to over 400,000 pounds per pile!

We offer 4 basic types of piles – Square Shaft (SS), Round/Pipe Shaft (RS), Combo Piles (SS+RS), and grouted Micropiles. They all have their benefits based on application – we used Combo Piles for the construction of our new office building in Centralia, Missouri.

And, while the verbiage is often used interchangeably, technically anchors are used in tension applications and piles are used in compression applications.

PB: Do you have a favorite pile type?

CH: While they all have their applications based on the specifics of the job, we have found that the Square Shafts typically provide the most bang for the buck and are the overall best choice for design loads up to 50 kip (also lowest cost per capacity in this range). Although the slender cross sections will not resist much lateral load, shaft buckling isn’t a problem as long as the soil surrounding the shaft is firm. Square shaft has the highest torque correlation and is the easiest to install with relatively small installation equipment, especially in dense soil. When lateral capacity is important, contractors like the Combo Pile which combines the installation benefits of a square shaft lead section with the lateral capacity of pipe shaft extensions.

PB: Why would one use Chance helical foundations instead of concrete?

CH: Hmmm, where to start? Concrete has its place in construction but clearly not our first choice for foundations. I’ll try to sum up the advantages of helical piles over concrete without making that its own interview!

| Chance Helical Piles | Concrete | |

| Capacity | Known capacity based on torque correlation | Estimated capacity based on soil data |

| Installation Speed | Installed and loaded immediately with no cure time | Can take 2-4 weeks to fully cure |

| Weather | Any weather the contractor is willing to work in (safely!) | Limited by heat, freezing temps, rain, snow |

| Mobilization | Ranging in lengths from 3 ft to 10 ft, can be stored ready to pull from inventory when a job requires | Scheduling concrete trucks and hoping they arrive on time May have special access requirements |

| Removable | Yes – and reusable | With difficulty |

| Environment | About half the overall CO2 impact of concrete (cradle to grave) | Requires extensive soil disruption; Mobilization produces high levels of CO2 |

PB: What applications are Chance helical piles used for?

CH: Pretty much any application where a structural load needs to be transferred to the soil, which is pretty much every structural load!. Being one of the first manufacturers to apply helicals into the commercial sector, we’ve had a lot of really interesting applications – famous sports stadiums (Dallas Cowboys, Detroit Lions, Philadelphia Phillies, SLC Olympics), national historic sites (Monticello, Dry Tortugas National Park, St. Augustine’s Cross), and even Katharine Hepburn’s house!

They can even be installed underwater or in eco-sensitive areas. There have been installations where the machine installing the helical piles drives along the boardwalk, installing helical piles as they go and never touching the surrounding environment!

Essentially, Chance helical piles are also used where other foundations fail – areas with expansive soils, high water tables, fill areas, and unstable soils.

PB: What are Chance Instant Foundation Systems?

CH: Although often overlooked, lighting applications also need effective foundations. The Instant Foundation System is a versatile system that allows for hassle-free installation and provides resistance to the lateral and axial loads encountered on pole-based structures that often rely on a single, coaxial foundation that will experience lateral forces.

PB: What are they made of?

CH: Chance Instant Foundations are made from steel and are similar to helical piles. They are a fraction of the weight of a pre-cast concrete base, are easy to transport and store, and can be easily re-positioned in a different location if needed. Bonus: all these things make them an eco-friendly and sustainable solution.

PB: Where are they used?

CH: Also sometimes referred to as wire-ready steel foundations, Instant Foundations are designed to provide a support base for applications such as modular and prefab structures, signage, bollards, EV charging stations, streetlights, rail infrastructure, small cell poles, and much more.

PB: Are they easy to install?

CH: YES! And actually this is one of the primary advantages that draws contractors to them. They are easy to install with virtually no spoils and definitely less messy (both in overflow and scheduling) than concrete pole base foundations. Our Instant Foundations can be screwed through most soils and even loose blacktop surfaces with no excavation. Since there’s also no need to pour concrete, they can be installed in any weather and in locations where it would be difficult to maneuver a concrete truck or large installation equipment.

PB: What types of tools does Chance offer?

CH: We offer several products including Kelly Bar adapters, drive tools, and more that are used in conjunction with our anchors and other products. For decades, Chance engineers have been researching and developing the torque-to-capacity relationship – meaning that the torque measured during installation will tell you how much load your pile is going to hold. So we have a digital torque indicator that measures torque during installation and sends the readings to your smart phone. This gives you a live read of exactly how your installation is going and when the desired capacity is reached.

PB: You also offer portable anchor installers for small foundations.

CH: That’s right. They are used for most shaft-driven guy anchors and smaller helical foundations. These compact drivers get into areas where large equipment cannot go. Counter-torque transmits through a torque bar from the drive head to the earth or other restraint. This frees the operator to perform the task of guiding the anchor path.

PB: What is HeliCAP®?

CH: That’s our Helical Capacity Design Software. You can enter a soil profile for a jobsite and then configure helical piles and anchors. It will calculate capacity, depth, torque – everything needed to get ready for a job. There are a lot of years of installations, soil types, and load testing all feeding the software with what we think is industry-best data.

PB: What does it do?

CH: When you enter your soil parameters, capacity results are calculated to help you design and build better and faster. Currently, over 4,000 users trust it for designing foundations, tiebacks, soil nails, and heavy guyed loads.

PB: How much does it cost?

CH: It’s free! Keep in mind that the data are only accurate for Chance products – so if you aren’t designing for Chance, it’s not going to help you. We’ve found that customers get mad when a project designed with HeliCAP but installed with a non-Chance product doesn’t work out! It just goes to show that not all helical piles are created equal. Create your HeliCAP account at www.hpsapps.com/helicap

PB: What is Chance University?

CH: Chance University is the online portion of the training required to become a Chance Certified Installer.

PB: Why become Chance Certified?

CH: It’s a great time to become Chance Certified! We’re currently expanding our course offerings (which are also free). Contractors who enroll in Chance U get the benefit of our immense installation experience to help grow their team expertise. Since Chance is such a well-recognized brand, an extremely cost-effective alternative to other systems, and are evaluated by all national building code agencies, customers find that the Chance Certified credential pays dividends! Also, only Chance Certified Installers can offer their customers our transferrable product warranty.

PB: What else is offered to Chance certified installers?

CH: 24/7 access to online training courses and in-person field training from your local distributor that will let you put your knowledge into practice. Certified Installers can attend hands-on seminars where they will design, install, and specify helical equipment using the latest developments in steel foundation technology.

PB: You offer a free Chance Technical Design manual, yes?

CH: We do love giving away free stuff, don’t we? Is it too much to say that this is the bible for deep foundations? Many Universities have used it for years as a teaching aid in their design courses. The 5th edition of the Tech Manual has been updated to include expanded product listings, latest building code evaluations – including seismic – as well as updated design examples. You can request your digital copy from our website or talk to your local distributor about getting a hard copy.

PB: What does the local distributor do?

We have an amazing network of distributors across the US and Canada, plus the UK. They work directly with contractors in their area for quotes, ready-to-mobilize product, tooling, engineering assistance, installation training – anything you need. Seriously, reach out to yours – these folks are the BEST in the business!

PB: What else do you want our readers to know about Chance?

CH: Oh my goodness, are we done already? If you made it this far – congratulations! If you’re looking for the people who have seen and done it all, who still design and manufacture where it all began in Centralia, Missouri, USA, who have the most building code evaluated products, and who want to give you free access to all the best tools in the business, reach out to your local distributor (see above) or contact us directly. Thanks so much, Pile Buck, this has been fun!