Ground Improvement Techniques Using OMS Vibroflots

OMS Pile Driving Equipment GmbH. provides a large selection of ground improvement techniques: “vibro compaction”, “vibro replacement”and “vertical drain”. As effective as our products are, choosing the correct equipment for your project might be a challenge. However, our experts on ground engineering can help you to decide on the best equipment for your project.

Today, the social and industrial growth has increased the importance of ground engineering. In fact, the profession plays a crucial role in projects such as power stations or the expansion of infrastructure systems like harbors and airports. Therefore, it is good to consult to an expert before deciding on the method of ground improvement.

Methods

Deep vibro compaction and vibro replacement methods are mainly to increase the strength of granular soils as well as unfavorable soil conditions. They are also beneficial for the improvement of deformation characteristics of the same type of soil. The two methods work by enhancing the bearing capacity of the weak layer. Then, they utilize the benefit of the improved resistance. Ergo, this results in a transition between deep foundation and soil stabilization. This way, the transition ensures a structural support below or on the improved ground surface both safety and economy wise.

As OMS team, we support our customers by recommending the best soil improvement equipment solutions. Vibro compaction and vibro replacement (stone columns) as well as vertical drain (wick drain) equipment of OMS have proved themselves in the global market from Europe to Middle East, South East Asia and America continent.

Vibro Compaction – Top Feed Ground Improvement Technique

Vibro compaction method is mostly suitable for fine granular soils with seismic risk. For this reason, experts suggest for land reclamation projects to decrease the risk of liquefaction. Furthermore, the technique is useful for the densification of sand-like soils on site through an OMS Vibroflotation prob. Due to the concurrent impact of saturation and vibration, loose sand particles changes into a more compact state. As a result, lateral confining pressure of the sand mass rises.

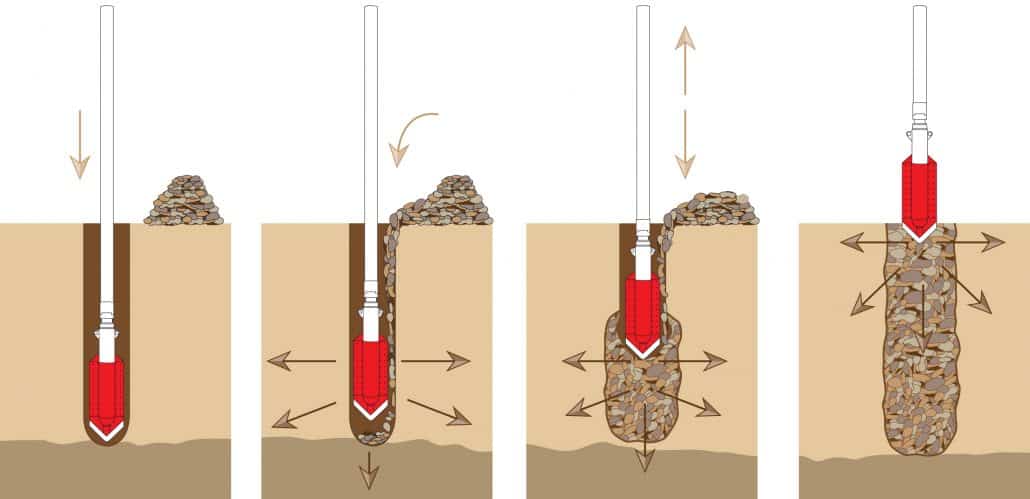

Vibro compaction top feed technique is convenient for medium to coarse-grained sand with silt content. Cohesive soils with silt and clay does not respond to vibratory compaction. The illustration below explains the operation:

Vibro Compaction

Tandem Free Hanging Ground Improvement:

The tandem vibro compaction includes two vibroflotation probes. Each prob suspends from the same crane. Land reclamation projects that require 20 – 25 m depth uses this configuration. The quality of compaction/stone column is controllable with a data logger supplied by OMS. Thence, the depth, compaction rate, time-related compaction and withdrawals can be measured and monitored. The data logger is also able to measure the gravel volume.

The single free hanging vibroflotation probe consists of the same interchangeable parts as Tandem. The depth of compaction can be deeper. Correspondingly, medium to small scale projects can be executed with a single free hanging system. Compared to the Tandem system, crane capacity of the vibroflotation probe is slightly smaller. Similarly to Tandem, the quality of compaction can be monitored with a “data logger”so that, depth, compaction rate, time-related compaction and withdrawals as well as gravel volume can be measured and monitored.

View more information here.

Which ground improvement method is suitable for fine granular soils with seismic risk and land reclamation projects to reduce liquefaction risk?

Vibro Compaction, especially the Top Feed technique, is recommended for fine granular soils with seismic risk and land reclamation projects to reduce liquefaction risk.

What are the advantages of the Tandem Free Hanging Vibroflotation probe in ground improvement projects requiring 20 - 25 meters depth, and how is the quality of compaction monitored?

The Tandem Free Hanging Vibroflotation probe, suitable for 20 - 25 meters depth, offers controllable compaction with a data logger, measuring depth, compaction rate, time-related compaction, withdrawals, and gravel volume.