Structural Steel Beams in Heavy Duty Pile Driving Operations

Structural steel beams play a major role in deep foundation systems where surface soils cannot support the loads of large infrastructure. Heavy duty pile driving relies on steel sections that can withstand high stresses, reach dense bearing layers and maintain integrity under long term loading. Contractors often work with experienced structural steel suppliers to ensure consistent quality and availability before installation begins, since foundation projects depend on reliable materials from the start.

Pile Driving Fundamentals

What Pile Driving Achieves

Pile driving installs long, high strength elements deep into the ground so they can transfer loads to stronger soil or rock layers. This process provides the stability required for bridges, port structures, energy facilities and industrial buildings built on challenging ground. When structural steel beams are selected, crews gain predictable material properties and dependable performance that supports accurate engineering design.

Why Structural Steel Beams Are Used

H section beams are widely used for driven foundations because they penetrate dense or mixed soils more effectively than many alternative pile types. Their manufactured geometry ensures strong resistance in compression, tension and bending. Since each beam is produced with controlled tolerances, designers can calculate capacity and deformation with confidence. Field crews can also splice beams to reach greater depths when needed.

Structural Steel Beams in Deep Foundation Work

Characteristics of H Section Beams

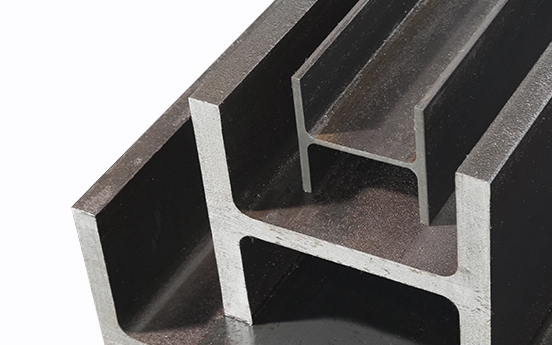

H section piles feature flanges and webs with nearly equal thickness, creating balanced load resistance in both directions. This allows them to support vertical loads and lateral forces. Their cross section shape enables deeper penetration with less driving resistance than larger displacement piles, which helps maintain progress in dense subsurface layers.

Advantages for Heavy Duty Pile Driving

H piles are used in major transportation corridors, marine bulkheads, industrial structures and utility foundations. Their high structural capacity and penetration ability make them suitable for projects requiring dependable performance under heavy loads. Field splicing procedures allow piles to extend as deep as necessary, which is essential when dense bearing layers are far below ground level.

Material and Grade Considerations

Steel pile beams are often specified with grades such as ASTM A992 or similar high strength materials. These grades provide consistent mechanical properties and controlled chemical composition. Engineers may specify coatings, galvanizing or specialized steel options where corrosion exposure is expected, especially in coastal, marine or submerged environments.

Installation Techniques and Field Considerations

Driving Equipment Selection

Impact hammers and hydraulic hammers are used when strong force is required to drive beams through dense layers. Vibratory equipment may be used in granular soils or regions with noise restrictions. Equipment selection is determined by soil conditions, allowable vibration levels and access around the worksite.

Driveability and Monitoring

Contractors monitor penetration per blow, final set, alignment and driving resistance to ensure the pile performs as designed. This documentation later supports capacity verification and long term performance assessments. If alignment, splice integrity or penetration rate suggests an adjustment is needed, crews modify the sequence to maintain correct installation.

Soil and Subsurface Challenges

Soil profiles may include soft clay, dense sand, gravel, cobbles or rock. Structural steel beams handle transitions between these layers with minimal deformation. If refusal occurs or unexpected resistance is encountered, crews evaluate whether to adjust the hammer energy, predrill or change the driving approach to maintain the design criteria.

Load Transfer and Long Term Performance

How Loads Move Through the Pile

Loads transfer into the ground through end bearing at the pile tip or friction along the sides. Many heavy duty structures rely on a combined mechanism where both shaft resistance and toe resistance contribute to overall capacity. Engineers study soil data to identify the governing mechanism in each project.

Performance Under Heavy Loads

Structural steel piles support facilities that experience significant vertical and lateral forces. Their ability to handle high axial loads, tension forces and bending moments makes them suitable for demanding foundation systems. They also cause limited soil displacement during driving, which helps protect adjacent structures in congested jobsite environments.

Durability and Service Life

Corrosion protection, weld quality, splice performance and soil chemistry all influence long term service life. Many foundations require coatings or barrier protection when piles remain in wet or marine environments. Detailed records of installation, material specification and load testing help ensure ongoing reliability throughout the structure’s lifespan.

Planning for Heavy Duty Applications

Specification and Engineering Requirements

Engineers review geotechnical data, design loads, corrosion risk and seismic requirements when selecting structural steel beams for driven foundations. Soil borings help determine pile length and section type. Construction schedules, material delivery and access constraints also guide planning.

Field Operations and Construction Logistics

Safe handling and alignment practices are essential. Driving logs and quality control documentation are recorded throughout installation. Splice inspections and weld checks must follow established procedures to ensure each pile behaves as a continuous load carrying member.

Verification and Testing

Static load tests, dynamic testing and integrity tests are often performed to verify capacity and confirm that the piles meet project specifications. These tests provide information on performance, settlement behavior and long term reliability.

Structural steel beams remain one of the most dependable options for heavy duty pile driving operations due to their strength, controlled fabrication and ability to penetrate difficult ground conditions. They support major infrastructure across transportation, marine, industrial and energy sectors with consistent performance when properly designed and installed. Contractors planning significant foundation work often collaborate with experienced steel supply services to ensure material availability and quality throughout the project. These partnerships help deliver deep foundation systems that meet the demanding load and durability requirements of modern construction.