Why Sealed Sheet Pile Interlocks Matter in Environmental Remediation Projects

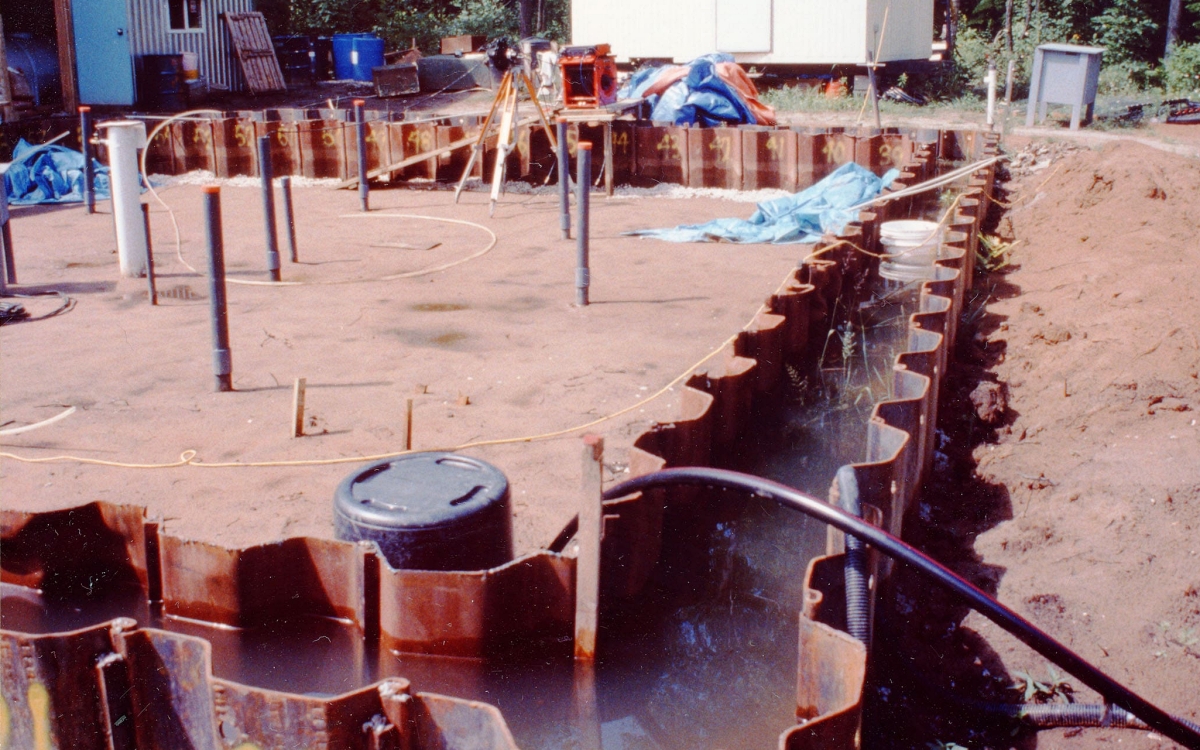

Environmental remediation projects often depend on subsurface barriers to prevent the migration of contaminated groundwater and soil gases. Steel sheet pile walls are widely used for this purpose because they can be installed quickly and provide structural stability, but long term containment performance depends heavily on one critical detail: the interlock. Even when piles are driven to competent strata, untreated joints can become the primary pathway for leakage, which is why modern projects increasingly rely on sealable sheet pile systems designed specifically for environmental isolation.

Understanding Leak Paths in Sheet Pile Walls

Where Leakage Typically Occurs

Steel sheet piles are manufactured with interlocking edges that connect adjacent sections into a continuous wall. While the steel web of the pile itself is impermeable, the interlock creates a longitudinal joint that runs from top to tip. In conventional installations, this joint is not inherently watertight and may allow groundwater to pass through under hydraulic gradient.

Leak paths typically develop at the interlock due to mill tolerances, minor deformation during driving, and soil intrusion. Field conditions such as cobbles, dense soils, or obstructions can slightly distort the pile shape, increasing the potential for micro gaps along the joint. Over time, differential settlement or changes in groundwater pressure may further compromise tightness.

Hydraulic Conductivity and Containment Performance

Environmental barrier walls are often designed to meet very low hydraulic conductivity targets. Remediation projects commonly require bulk wall permeability values that align with regulatory standards for slurry walls or other containment systems. If the interlock is not sealed, the effective hydraulic conductivity of the wall may be governed by joint leakage rather than steel thickness or embedment depth.

This distinction is important because contaminant plumes move along preferential pathways. Even narrow continuous voids can allow measurable migration when hydraulic gradients are present. For projects involving hydrocarbons, chlorinated solvents, or heavy metals, small leak paths can undermine remediation objectives and increase long term liability.

Why Conventional Sheet Piles Fall Short in Containment

Structural Performance Versus Hydraulic Performance

Traditional sheet pile walls are often designed primarily for earth retention and excavation support. In those applications, minor seepage through interlocks may be acceptable or controlled through dewatering systems. However, environmental remediation requires hydraulic performance that matches or exceeds structural demands.

A conventional sheet pile wall without joint treatment may perform well as a retaining system but fail to provide the low permeability needed for containment. Sealants applied externally or along the exposed portion of the wall rarely address the full embedded length, leaving the subsurface joint untreated.

Soil Intrusion and Joint Deformation

During driving, soil can enter the interlock cavity. Fine grained soils may smear along the joint, while granular materials can lodge inside and prevent tight engagement. In vibratory installation, interlock friction and vibration may alter alignment slightly, creating inconsistent contact along the wall.

Because the interlock runs the entire depth of the pile, these conditions are repeated for each sheet. In long remediation walls, the cumulative effect of untreated joints can create a network of potential leakage pathways.

Tremie Grouting and Mechanical Sealing Approaches

Tremie Grouting of Interlocks

One proven method for improving hydraulic performance involves flushing and sealing the interlock cavity after installation. In systems that incorporate accessible joint cavities, the interlock can be cleaned and then filled using tremie grouting techniques. Tremie placement allows grout to be introduced from the bottom upward, reducing air entrapment and ensuring full contact along the joint length.

Depending on project requirements, clay based, cementitious, or polymer modified grouts may be used. These materials are selected for compatibility with groundwater chemistry and target permeability. When properly installed, grouted interlocks significantly reduce the potential for continuous leak paths.

Mechanical and Inflatable Sealing Systems

For temporary works or projects requiring retrievable components, mechanical sealing systems may be used. Inflatable elements can be inserted within specially designed cavities to provide compression against the joint surfaces. These systems allow short term isolation while excavation or treatment activities are underway.

Mechanical approaches are typically chosen when removal or adjustment is anticipated. While they may not always achieve the same long term durability as grout, they offer flexibility for phased remediation projects.

Inspection and Verification of Joint Integrity

Importance of Quality Assurance Documentation

In environmental remediation, performance verification is as important as design intent. Because the interlock represents the primary potential leak path, quality assurance programs often focus on documenting pile driving, joint cleaning, and sealing procedures for each individual sheet.

Detailed records reduce uncertainty and provide evidence of compliance with regulatory requirements. When agencies review containment installations, documented joint treatment can demonstrate that hydraulic performance objectives were addressed systematically rather than assumed.

Fibre Optic and Down Hole Inspection

Inspection technologies have evolved to allow direct examination of joint cavities prior to sealing. Down hole fibre optic cameras can be used to confirm that the cavity is open along its full length and free of obstructions before grout placement. Visual verification helps ensure that flushing operations have removed soil intrusion and that the sealant will bond effectively.

Post sealing inspection and pressure monitoring may also be incorporated into the quality control process. These steps align with broader trends in joint sealing technology for containment walls, where inspection and documentation are integrated into installation procedures rather than treated as optional add ons.

Regulatory and Long Term Considerations

Environmental regulations governing contaminated sites often require containment systems to demonstrate defined performance criteria. Agencies may specify maximum allowable hydraulic conductivity or require long term monitoring of groundwater levels and contaminant concentrations. In such contexts, untreated sheet pile interlocks represent an avoidable risk.

By addressing the joint directly, engineers can align steel sheet pile walls with the performance expectations traditionally associated with slurry trench walls or composite barriers. This integration of structural capacity and hydraulic control supports both excavation stability and plume containment within a single system.

Long term durability also depends on material compatibility and proper embedment into low permeability strata. However, even optimal embedment cannot compensate for continuous leakage along the wall alignment. The interlock therefore becomes the most critical variable in determining whether a sheet pile barrier functions as a true containment wall or merely as structural support.

Sealed interlocks transform the role of steel sheet piles in environmental remediation projects. While the steel web provides structural integrity, the joint determines hydraulic performance. By identifying typical leak paths, understanding the limitations of untreated interlocks, and applying tremie grouting or mechanical sealing methods supported by inspection and documentation, project teams can significantly improve containment reliability.

As remediation standards continue to emphasize measurable performance and defensible installation records, attention to interlock sealing will remain central to the success of groundwater isolation systems. Addressing the joint is not a minor detail. It is the defining factor that allows a sheet pile wall to function as an engineered environmental barrier rather than simply a line of driven steel.