Why Reaction Systems are the Most Critical Variable in Static Pile Load Testing

Static pile load testing is widely regarded as the most reliable method for verifying foundation performance under design loads. While much attention is placed on load magnitude and pile behavior, the reaction system used to resist the applied force is often the most critical variable influencing test accuracy, safety, and reliability. A poorly designed reaction system can compromise test results regardless of how well the pile itself performs.

As project demands increase and test loads grow larger, understanding the role of reaction systems has become essential for engineers and contractors involved in foundation verification.

The Role of Reaction Systems in Static Testing

Load Transfer Fundamentals

In a static pile load test, the applied load must be resisted by an external system capable of providing equal and opposite force. Reaction systems serve this purpose by transferring load away from the test pile and into surrounding ground or structural elements. Common reaction methods include reaction piles, anchor systems, and kentledge platforms, each relying on different load transfer mechanisms.

If the reaction system deforms, shifts, or interacts with the test pile, the measured settlement and load response may reflect reaction movement rather than true pile behavior. This makes reaction system performance fundamental to test validity.

Why Reaction Behavior Influences Test Results

Static load testing assumes that all measured displacement occurs within the test pile and supporting soil. When reaction elements experience movement or load redistribution, test data can become distorted. Even small amounts of reaction system deflection can lead to inaccurate interpretation of pile stiffness, capacity, or failure thresholds.

For this reason, reaction system design must receive the same level of scrutiny as the pile itself, particularly for high-capacity or long-duration tests.

Reaction Piles and Their Limitations

Interaction Between Test and Reaction Piles

Reaction piles are commonly used due to their efficiency and reduced material requirements compared to kentledge systems. However, their effectiveness depends heavily on spacing, embedment depth, and soil conditions. If reaction piles are placed too close to the test pile, overlapping stress zones can cause interaction that reduces resistance and alters load transfer behavior.

This interaction can lead to underestimating pile capacity or misinterpreting settlement data. Proper spacing and geotechnical evaluation are critical to minimizing these effects.

Installation Quality and Load Capacity

Reaction piles must be installed with the same care as production piles. Inconsistent installation methods, inadequate embedment, or unverified load capacity can result in reaction pile failure before the test pile reaches target load. This not only invalidates test results but also introduces significant safety risks during testing.

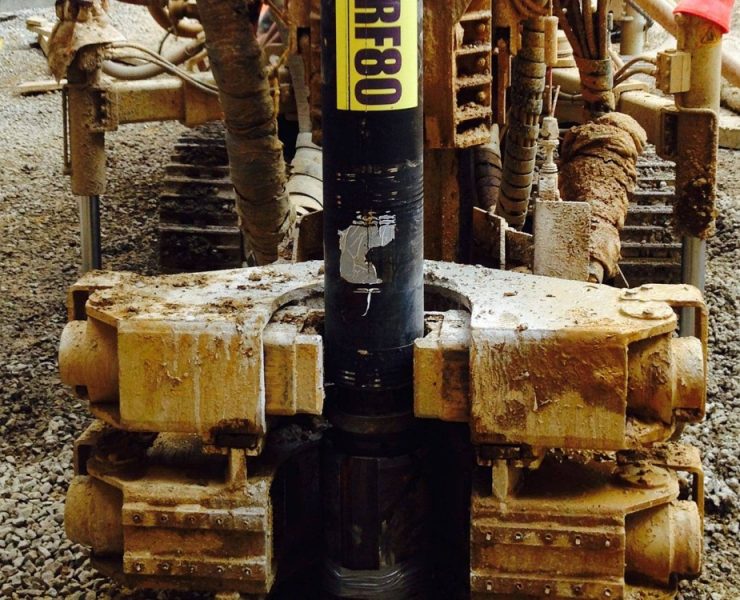

Reliable pile load testing equipment plays an important role in detecting early signs of reaction pile instability by providing accurate load feedback throughout the test sequence.

Kentledge Systems and Structural Considerations

Space and Weight Requirements

Kentledge systems rely on dead weight to resist applied loads, often using stacked concrete or steel blocks. While effective, these systems require substantial space and stable bearing conditions. On constrained job sites, providing sufficient footprint and ground support for kentledge can be challenging.

Uneven bearing beneath the kentledge stack can cause settlement or tilting, which directly affects load application and measurement accuracy. These risks increase as test loads grow larger.

Structural Stability and Safety

High-capacity kentledge systems store large amounts of potential energy. Any instability in stacking or support conditions can lead to sudden movement or collapse. Ensuring structural stability requires careful design, load distribution analysis, and continuous monitoring during the test.

Reaction system performance is closely tied to safety outcomes, making proper planning essential for protecting personnel and equipment during testing operations.

Anchor-Based Reaction Systems

Load Transfer into Soil or Rock

Anchor-based reaction systems transfer load into deeper soil layers or bedrock using tension elements. Their effectiveness depends on soil strength, anchor installation quality, and bond length. Poorly installed anchors may experience creep or pullout during sustained loading.

These movements can introduce time-dependent displacement that complicates interpretation of load settlement curves. Monitoring anchor behavior throughout the test is critical for maintaining data integrity.

Long-Duration Testing Challenges

Sustained load tests and creep tests place extended demands on reaction systems. Over time, minor movements in anchors or reaction frames can accumulate into measurable displacement. Distinguishing between pile settlement and reaction movement becomes increasingly difficult without precise instrumentation.

Accurate measurement systems are essential for identifying and correcting these issues before test results are compromised.

Reaction Frames and Load Distribution

Frame Stiffness and Alignment

Reaction frames must distribute load evenly across reaction elements while maintaining vertical alignment with the test pile. Frame flexibility or misalignment can introduce bending stresses and uneven load paths. In high-capacity tests, even minor misalignment can significantly affect measured response.

Rigid frame design and precise setup help ensure that applied loads remain concentric and representative of design conditions.

Effects of Confined Job Sites

Confined job sites often restrict reaction frame geometry and component placement. Limited clearance can force unconventional configurations that increase the risk of uneven load transfer. These constraints make careful structural evaluation of the reaction system even more important.

In such environments, dependable pile testing equipment and experienced setup personnel play a key role in maintaining system performance.

Measurement Accuracy and Reaction Stability

Load Measurement Reliability

Accurate load measurement depends on stable reaction conditions. If reaction elements move or redistribute load, measured force values may fluctuate even when applied pressure remains constant. This can obscure true pile behavior and complicate data analysis.

Using properly calibrated pile testing equipment helps ensure that load readings remain consistent and traceable throughout the test duration.

Displacement Monitoring Considerations

Displacement measurements are particularly sensitive to reaction system performance. Reference beams or monitoring points must be isolated from reaction movement to capture true pile settlement. Reaction instability can invalidate displacement data even when load measurements appear stable.

Careful placement of reference systems and continuous monitoring are necessary to maintain confidence in test results.

Designing Reliable Reaction Systems

Early Coordination and Site Evaluation

Reaction system design should begin early in the project planning phase. Evaluating site constraints, soil conditions, and access limitations allows engineers to select appropriate reaction methods and avoid late-stage modifications.

Early coordination between geotechnical engineers, structural designers, and construction teams reduces the likelihood of reaction-related issues during testing.

Matching Reaction Systems to Test Demands

No single reaction system is suitable for all static pile load tests. High-capacity tests, long-duration loading, and confined sites each place different demands on reaction design. Selecting the right approach requires balancing space, cost, safety, and data quality.

Well-designed reaction systems supported by reliable pile testing equipment help ensure that static pile load tests deliver accurate, defensible results. As testing demands continue to increase, reaction systems will remain the most critical variable influencing the success of static pile load testing programs.