Rapid Impact Compaction (RIC) Techniques: Modern Solutions for Ground Improvement in Challenging Soils

Rapid impact compaction, often referred to by its abbreviation RIC, is a ground improvement process that has emerged as an effective solution for improving loose, granular soils in a range of construction settings. As urban development and infrastructure projects increasingly encounter variable soil conditions, engineers need methods that can reliably increase soil strength and stability without resorting to lengthy excavation or deep foundation work. This introduction sets the context for why RIC is gaining traction as part of modern ground improvement equipment techniques that provide efficient soil preparation before key project activities commence.

Understanding Rapid Impact Compaction

What Rapid Impact Compaction Involves

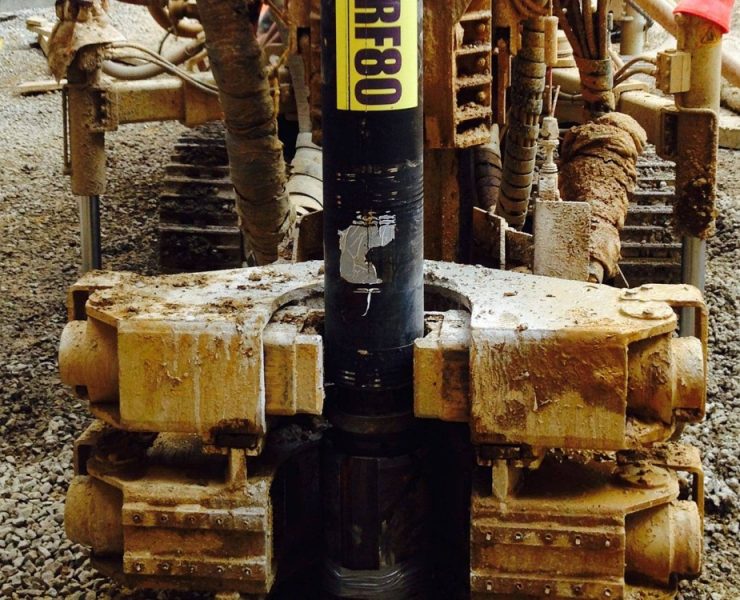

Rapid impact compaction is a surface-based dynamic soil improvement approach that transfers energy into the ground to densify soil layers. The process typically involves a hydraulic hammer mounted on an excavator platform repeatedly striking a large circular plate that remains in continuous contact with the surface. The cumulative effect of these high-frequency impacts pushes soil particles closer together, increasing density and reducing voids between grains. This method is most often applied to granular soils such as sands, gravels, and some controlled fills, where traditional compaction methods might be less effective or feasible. The depth of influence typically reaches about four to six meters below the surface, depending on soil type and compaction parameters.

Historical Evolution of The Method

The development of rapid impact compaction traces back to work on rapid runway repair techniques where quick and effective soil densification was essential. Over time, RIC evolved for civil construction use because it could bridge the gap between shallow surface compaction and deeper dynamic compaction methods. Modern implementations now benefit from advanced control systems that allow operators and engineers to monitor impact energy, penetration depth, and the number of blows per grid point, helping to tailor the approach for different project needs.

The Science Behind RIC Soil Improvement

How RIC Transforms Soil Properties

The underlying principle of rapid impact compaction is the controlled transmission of dynamic energy into the ground. As the hydraulic hammer strikes the compaction foot, energy travels into loose soil layers, redistributing particles into a denser configuration. This densification increases the soil’s friction angle and stiffness, which in turn enhances its ability to support loads. Because the impact foot remains in contact with the ground, energy transfer is more efficient and controlled compared to some older methods where weights were dropped from heights with less precise guidance.

Because the compaction foot remains in continuous contact with the ground, rapid impact compaction does not generate airborne projectiles in the way some other impact-based ground improvement methods can. This improves safety around the machine and makes the method suitable for sites where work is carried out close to existing structures or active operations, subject to site-specific safety planning.

Effects on Bearing Capacity and Settlement

One of the primary goals of ground improvement is to increase the bearing capacity of the soil so that structures constructed above it can be supported without excessive settlement. By densifying soil and reducing its compressibility, RIC decreases the risk of future differential settlement that can damage foundations or slabs. In many cases, engineers use this process to allow shallow foundation systems to be employed where previously deep foundations or piles might have been required.

Applications of Rapid Impact Compaction

Urban and Infrastructure Projects

Rapid impact compaction is widely used in urban construction where space, access, and proximity to existing structures limit the use of large, deep treatment equipment. For example, RIC can prepare soil under industrial buildings, warehouse floors, parking areas, and road embankments without generating large volumes of spoil or requiring extensive excavation. The relatively compact equipment can often be mobilized quickly, and because it induces lower vibration levels than some competing methods, it is suitable for sites near sensitive structures.

Challenging Soil Conditions

Loose fills, reclaimed land, and soils with variable composition present special challenges because inconsistencies in density or composition can lead to uneven settlement or instability under loads. Rapid impact compaction is effective in many of these contexts because the grid pattern of impact points ensures consistent treatment across the surface area. RIC has also been employed in areas with complex soil histories where traditional compaction might struggle, such as in urban brownfield developments.

Benefits and Considerations

Efficiency and Project Timelines

One of the major advantages of rapid impact compaction is its speed relative to many conventional soil improvement methods. Because the system treats large areas in grid patterns with controlled, repeated impacts, projects can achieve design-required soil densities in a fraction of the time compared to slower alternatives. This accelerated timeline can have significant cost implications for large scale developments, and for projects where scheduling is tight, the reduction in preparation time can allow follow-on construction activities to begin sooner.

Environmental and Practical Advantages

Rapid impact compaction does not require water addition, chemical stabilizers, or soil removal and replacement to achieve improved soil conditions. Consequently, it creates minimal spoil and has a smaller onsite footprint for material handling than traditional solutions. Because many soils can be treated in place, RIC can also reduce the carbon footprint associated with hauling and importing engineered fills or extensive excavation work, aligning with sustainable construction practices.

Limitations and Soil Suitability

Despite its benefits, RIC is not universally applicable. The technique is most effective on soils with low silt and clay content, such as sandy or gravelly materials. High fine content soils may not densify effectively under rapid impact conditions, and deeper problematic layers might still require alternative methods, such as vibro compaction or dynamic compaction. Geotechnical assessment is essential to determine whether RIC is the optimal choice for a particular project site.

Integrating RIC in Modern Construction

Design Integration and Quality Assurance

For successful implementation of rapid impact compaction, engineers often start with a trial area to determine optimal impact spacing, blow counts, and energy settings. Data from these preliminary tests guide the full treatment plan, helping to verify that criteria such as bearing capacity and density improvements are met. Modern equipment often includes monitoring systems that record energy delivery and soil response, enabling documentation that treatment requirements have been fulfilled before moving forward.

RIC as Part of A Broader Ground Improvement Strategy

While RIC is powerful in many contexts, it is often used alongside other geotechnical techniques in comprehensive ground improvement designs. For instance, deep dynamic compaction might be reserved for deeper layers, while RIC addresses shallower strata. In other instances, RIC may be paired with reinforcement solutions like stone columns or controlled modulus columns to create a composite ground that meets complex load requirements. Selecting the right combination depends on soil conditions, project goals, and economic considerations.

Future Directions in Soil Improvement

As construction projects continue to push into challenging and previously underutilized land, methods like rapid impact compaction will remain valuable because they offer a way to improve subgrade conditions efficiently and reliably. Ongoing research into soil behavior under dynamic loads and technological advances in monitoring and control will likely make RIC even more precise and adaptable to a wider range of soil types.

In summary, rapid impact compaction has established itself as a versatile, cost effective ground improvement tool that bridges the gap between traditional shallow compaction and deeper, more invasive techniques. Its ability to increase soil strength, reduce settlement potential, and shorten project timelines makes it a compelling option in many contexts where ground stability is key. The ongoing refinement of soil densification methods positions RIC as a continuing solution in modern geotechnical engineering practice.

It densifies loose granular soils to improve bearing capacity and reduce settlement beneath foundations and pavements.

RIC works best on sandy or gravelly soils with low silt and clay content. What is rapid impact compaction (RIC) used for in construction?

Which soils are suitable for rapid impact compaction?