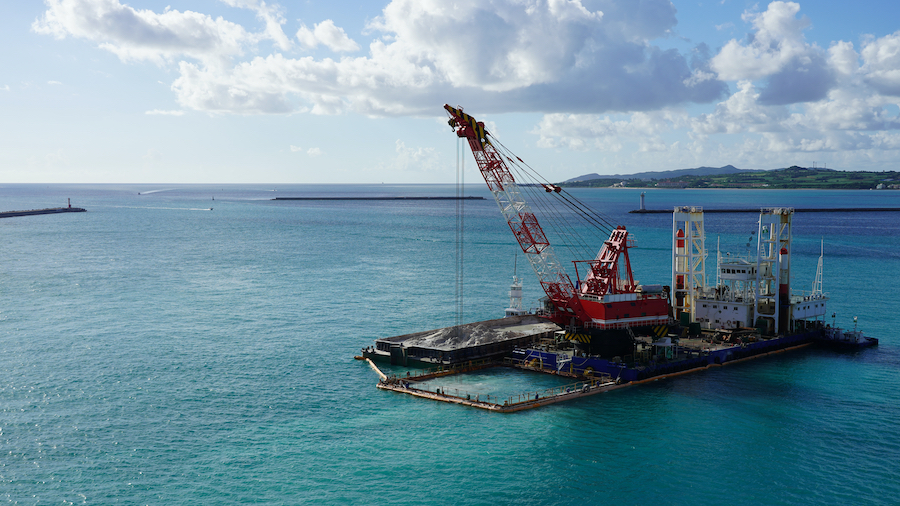

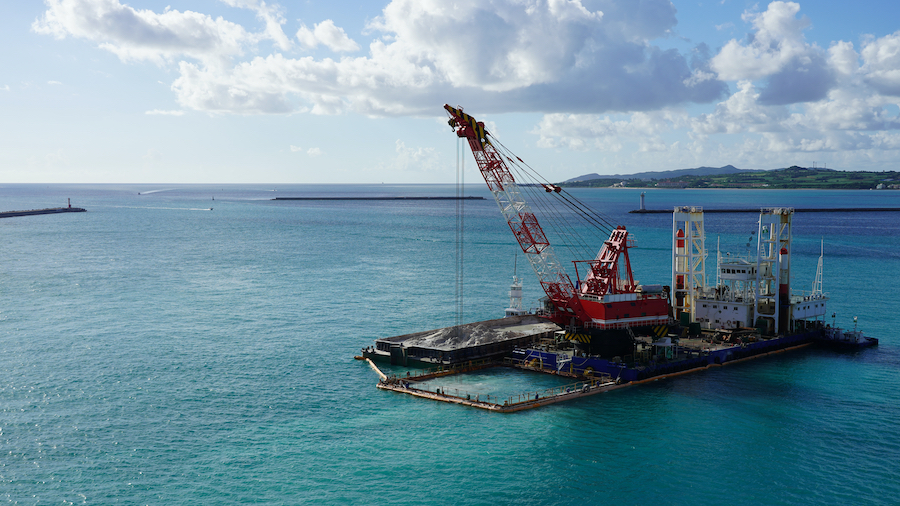

Floating Cranes for Marine Construction

View the complete article here

Cranes are an important part of construction on land projects. You can also use them for marine construction. You will use some of the same criteria in selecting a crane whether you are building on soil or water. But placing a big piece of equipment on top of a floating device has its own challenges.

Floating Cranes

These heavy-duty cranes are often used for constructing ports and bridges. They are useful for loading and unloading heavy items to and from ships. They are also used for transferring equipment from one vessel or platform to another, moving around equipment on the sea deck, and recovering or placing equipment on the seabed.

Challenges

Floating cranes have some challenges that are different from their land cousins. These include:

- Wind and weather

- Seabed suction

- The motion and stability of the vessel

- Sea forces

All of these challenges must be considered when determining the load capacity. What the crane can handle will always be less than its stated capacity on land. The reduction of capacity can be anywhere from 90% all the way down to 50%.

Crane Vessels

Marine rigging companies provide cranes that can handle the harsh environment of offshore and marine operations. Designing cranes takes into account load conditions and stress. Project managers typically are focused on loading capacity when selecting a crane. The crane’s capacity depends on several factors, including the type of vessel to which it is attached.

Common Crane Vessels

First introduced in the 14th century, common crane vessels are used to haul and lift about 2,500 tons. They are moveable; the crane can be brought to the location of the item to be lifted.

Sheerlegs

These vessels are capable of carrying a lot of weight – 50 to 4000 metric tons. But this type of crane vessel can’t be moved.

Semi-Submersible

This type of crane vessel balances the weight placed upon it by partially submerging into the water. This, obviously, keeps the crane from falling over into the water. The maximum weight limit for semi-submersible crane vessels is about 14,000 metric tons.

Float Your Boat

Getting a vessel with a big crane attached to float is not the easiest thing to do. Complex calculations go into determining the overall density and volume of the crane vessel compared to the amount of water it displaces. And, the amount of buoyancy pressure it produces at a particular depth. Without knowing those details, your boat won’t float. These calculations are also used to figure out the crane vessel’s maximum carrying weight.

That’s a Big Barge

According to the Guinness Book of World Records, the Thialf in the Netherlands is the largest floating crane ship in the world. Its two 311-foot cranes work in tandem to lift up to 14,200 metric tons – 31.3 million pounds! This crane ship holds up to 736 people and includes a helicopter pad. Its draught is increased by flooding its hull. This allows the Thialf to submerge by 20 meters (65.6 feet) and provides the stability necessary for it to lift mammoth loads. It also allows it to handle rough seas.

Crane Types

There are several types of marine cranes available including:

Stiff Boom Crane

These are designed to handle general cargo. The crane uses a hydraulic winch to lift a load. A boom is used to lower or raise to the desired lifting height. Stiff boom cranes are perfect for handling fragile loads, since it lifts straight up and straight down. This type of crane has little to no drift allowing the operator to suspend a heavy load indefinitely. It is the best crane to use for reaching over fences and walls. The hoses and cylinders are located inside the machinery. This protects them from harsher conditions. As well, the lift energy goes to the winch and then the cylinder, reducing strain on the crane itself.

Telescopic Boom Crane

Telescopic boom cranes have permanently attached winches. Wire rope allows more precise placement of loads. Like the stiff boom crane, it can suspend heavy loads for a long time with no drift. This is due to the holding valves and the fact that the winch is primarily used when lifting. The energy during the lift goes to the winch, then to the cylinder and crane structure.

Knuckle Boom Crane

Knuckle boom cranes have less joints, making them easier to maintain. However, they are subject to a lot more wear and tear. This is due to the lift energy going to the boom structure and extension cylinders first, then to the lift cylinder and crane structure. Knuckle boom cranes are not able to suspend loads. They are used only for the loading and unloading of materials. They are often used on large-decked vessels and fixed platforms.

Foldable Telescopic Boom Crane

This type of crane requires minimum desk space as it can fold into a compact size. It works like a giant human finger. It has two booms; a main boom and an outer boom. These are attached to a knuckle so that the whole boom structure moves in and out. This is similar to how our knuckles move our fingers.

Wrap Up

Floating cranes are essential to the marine construction and offshore oil industries. Although they function much like cranes used on land, the size and stability of the vessel, as well as wind and weather conditions, can reduce the maximum load that can be lifted. For some projects, a floating crane is the only option to get the job done.

View the complete article here

What challenges do floating cranes face in marine construction?

Challenges include wind, weather, seabed suction, vessel motion, and stability, impacting the crane's load capacity, which is reduced compared to its land capacity.

What are the types of crane vessels commonly used in marine construction?

Common crane vessels, sheerlegs, and semi-submersible vessels are used, each with specific weight capacities and mobility characteristics for different marine construction needs.