Helical Anchors: The Superior Choice for Mooring Applications

Offshore, helical anchors stand alone as the superior choice for mooring applications. With better holding power and minimal marine disturbance, helical anchors offer many benefits for many underwater applications.

On land, piling and anchoring solution are abundant and helical anchors have always been known to be cost-effective, versatile, and easy to install. Offshore, however; helical anchors stand alone as the superior choice for mooring applications. First used in the marine environment to secure oil pipelines to the ocean floor, helical anchor technology has been proven to be a successful and environmentally sensitive alternative to traditional mushroom, deadweight, and pile anchors for boat owners, harbormasters, and marine construction and civil engineering firms.

Commonly, helix mooring anchors are installed into the marine floor from the surface by work boats with drill rigs or divers utilizing submersible equipment and anti-torque devices. The helix plates are installed through the silt into good bearing soils, and the chains or lines are connected to the mooring or platforms above. With 4-5 times the holding strength when compared to other alternatives, insurance companies have even offered special incentives to boat owners who use helical moorings in hurricane-prone areas.

Helical Anchor Mooring Applications

- Boat moorings

- Floating docks

- Piers

- Aquaculture equipment

- Navigation markers

- Walkways

- Scientific equipment stabilization

- Offshore “green” energy

- Pipelines

- Seawalls

Helical Anchor Holding Capabilities

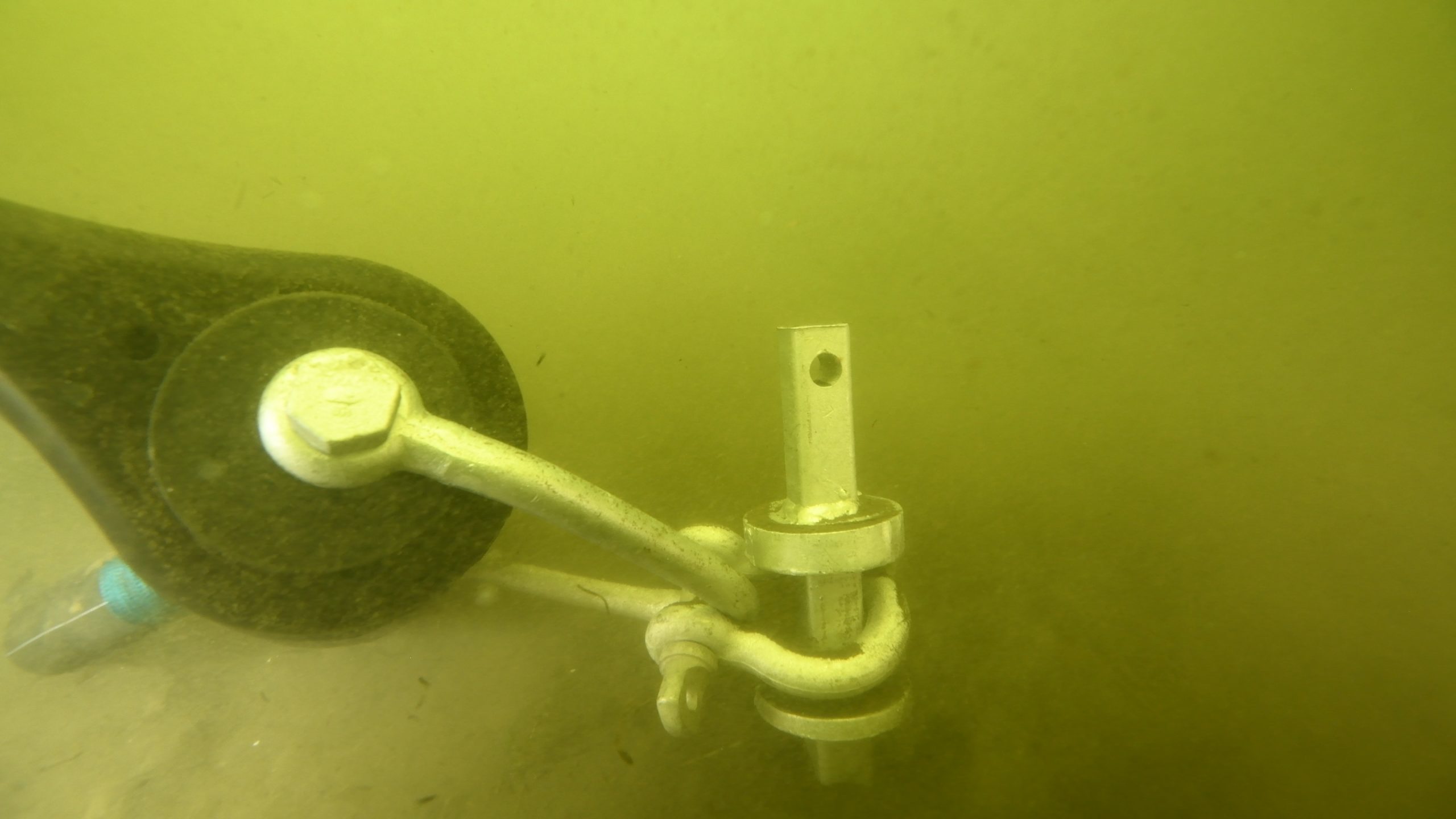

The anchor pictured is a popular firm soil anchor. Its overall length is about 7-feet, and there are two helices welded to the central shaft. The top helix plate is 10-inches in diameter and the lower one is 8-inches. Although this anchor weighs just over 100 lbs., it can deliver a holding force in excess of 20,000 lbs. in good competent soils. When there is a layer of soft soil over the competent soils, an extension can be added between the anchor shaft and the mooring termination. The addition of the extension ensures that the helices are sufficiently buried into good holding soils to deliver satisfactory holding capacity. When mud and silt are the primary subsoil, it is common to use additional extensions or larger diameter helices. The added installation depth and/or number and size of the helices will compensate for the weaker soils.

To further illustrate the capabilities and advantages of a helical mooring anchor, let’s look at some sample test data. The chart below shows the results of the first pull test performed in Vineyard Haven, Massachusetts under the guidance of area harbormasters, a marine industry reporter and a representative of BoatUS. These results are typical of all load tests performed.

Vineyard Haven, Pull Test Results

| Mooring Type | Bottom Condition | Breakout Force |

| 350-lb Mushroom | 5 ft. deep in mud | 2,000 lb |

| 500-lb Mushroom | In sand bottom | 1,700 lb |

| 3,000-lb Concrete USCG block | Set in mud | 2,100 lb |

| 6,000-lb Cement Block | On sand bottom | 3,200 lb |

| 8/10 Helix Anchor | Soft clay mud | 20,800 + lb |

In cases where more holding power is required, multiple helical mooring anchors can be easily grouped together. Most commonly, a three-point system can be installed to triple the holding of what the single helical mooring anchor offers. Bridled together and sized accordingly, these systems can be engineered to secure very large vessels with field proven tensile loads up to 200,000 lbs.

Eliminating Drag

Another benefit to the helical anchor is the elimination of drag. Drag is where boaters might throw out one of the traditional anchoring options, but the anchor doesn’t grab hold where it lands, so as the boat moves, the anchor drags until it finds better holding. Helical anchors don’t have a problem with drag; once they are installed, they are set, and will not move unless you decide to remove them. No drag means shorter scope requirements, which harbormasters appreciate as it maximizes the number of boats the harbor can house and translates to increased revenue for the harbor.

By eliminating drag, helical anchors also have little impact on sensitive ecosystems and allow marine life in the areas where these anchors are placed to carry on undisturbed. Because of this, these anchors are the best solution for environmentally sensitive areas and have been recommended by state agencies and scuba diving companies across the world.

More Helical Anchor Benefits

- Superior holding power

- Minimal marine disturbance

- Longer lifespan

- Shorter scope requirements

- Allows for suspended ground tackle

- Easier to transport and handle vs. concrete

- Instant torque-to-capacity feedback during install

- No hammering or loud vibrations

- Removeable and reusable

- No need to upgrade or reinstall after initial installation

- Steadfast holding even in variable wind conditions

With the largest network of helical anchor distributors in North America and 150 years of combined CHANCE engineering experience in-house, Hubbell Power Systems, Inc. is your go-to partner for helical anchors for mooring applications. To learn more or for mooring project support, contact today!

How do helical mooring anchors compare in holding strength to traditional anchors like mushroom or concrete blocks?

Helical mooring anchors offer 4-5 times the holding strength compared to alternatives like mushroom or concrete blocks, with demonstrated capacities exceeding 20,000 lbs.

What are the benefits of using helical anchors for mooring, especially in environmentally sensitive areas?

Helical anchors provide superior holding power, minimal marine disturbance, eliminate drag, have a longer lifespan, and are environmentally friendly, making them ideal for sensitive ecosystems and recommended by state agencies and scuba diving companies worldwide.