Chapter 11 – Ground Anchors & Soil Nails

- Chapter 1 – Foundation Investigations

- Chapter 4 – Footing Foundations

- Chapter 5 – Pile Foundations

- Chapter 6 – Cast-In-Drilled-Hole Piles

- Chapter 7 – Driven Piles

- Chapter 8 – Static Pile Load Testing and Pile Dynamic Analysis

- Chapter 9 – Slurry Displacement Piles

- Chapter 11 – Ground Anchors & Soil Nails

- Chapter 12 – Cofferdams and Seal Courses

- Chapter 14 – Specialty Piles and Special Considerations for Pile Foundations

Foundations Manual by Caltrans

11-1 Introduction

Chapter 5, Pile Foundations-General, classifies ground anchors as special case foundations. Sub horizontal ground anchors, sometimes referred to as tiebacks, are used for earth retaining structures where it is not feasible to excavate and construct a footing foundation or pile cap for a conventional retaining wall. Vertical ground anchors, sometimes referred to as tension piles or tiedowns, are used generally for seismic retrofitting or existing footings where uplift and overturning must be prevented.

11-2 Sub Horizontal Ground Anchors

Sub horizontal ground anchors are used for temporary and permanent structures. The use of sub horizontal ground anchors with sheet pile or soldier beam shoring permits taller walls and deeper excavations than are possible with cantilever type construction–up to 35 feet or so depending on soil properties versus 15 feet for cantilever construction. Walls can be built much higher than 35 feet by using high strength sheet pile or soldier beams with multiple rows, or tiers, of sub horizontal ground anchors.

11-2.1 Components

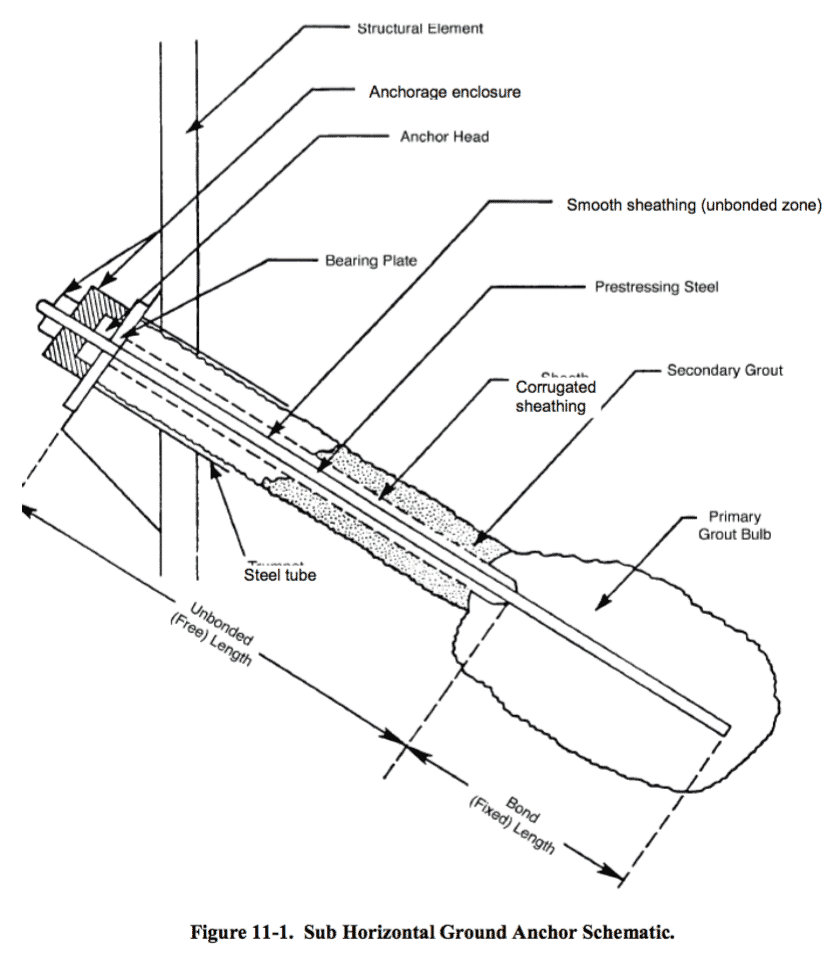

Sub horizontal ground anchors are constructed by drilling holes at a slight angle (usually 15 degrees) off the horizontal axis. Afterwards a special prestressing system is installed and the tip portion, known as the bonded length, is grouted. The bonded length acts as an anchorage by distributing the prestressing force to the surrounding soil. The unbonded end is secured with an anchor head. Refer to Figure 11-1 for a sub horizontal ground anchor schematic. Refer to Bridge Standard Detail Sheet (XS) 12-040 for sub horizontal ground anchor details.

The following list describes various sub horizontal ground anchor components:

COMPONENTDESCRIPTIONPrestressing Steel – Support MemberThis transfers load from the wall reaction to the anchor zone and is generally a prestress rod or strand.Bond LengthThe portion of prestressing steel fixed in the primary grout bulb through which load is transferred to the surrounding soil or rock. Also known as the anchor zone.Unbonded LengthThe portion of the prestressing steel that is free to elongate elastically and transmit the resisting force from the bond length to the wall face.AnchorageThis consists of a plate and anchor head or threaded nut and permits stressing and lock-off of the prestressing steel.GroutThis provides corrosion protection as well as the medium to transfer load from the prestressing steel to the soil or rock.

In addition to enabling the construction of higher/taller walls and deeper excavations, sub horizontal ground anchors serve another useful purpose. The system provides an open unrestricted work area adjacent to the wall and inside the excavation since the only part of the system that projects beyond the wall is the relatively small anchorage device.

For permanent structures, the Contractor is responsible for providing a sub horizontal ground anchor system that conforms to the design requirements shown on the contract plans and meets or exceeds the testing requirements specified in the contract. Sub horizontal ground anchor shoring designs are often proprietary and require sophisticated engineering techniques and calculations submitted by the contractors and consultants. The designed bonded length is based on site specific soil parameters/mechanical properties. In accordance with the contract specifications1, the Contractor submits sub horizontal ground anchor shop drawings and design calculations to Structure Design, Documents Unit, for distribution, review, and authorization, and notifies the Engineer of the submittal. The Designer, Geoprofessional, staff specialist for Earth Retaining Systems in Structure Policy and Innovation, the DES Prestressing Committee and Structure Construction field personnel all review the shop drawings. The Designer authorizes the shop drawings based on the recommendations of the individual units reviewing the drawings. These individuals and groups can be consulted for help in answering any questions that may arise in the field during construction. In addition, the Structure Construction Substructure Technical Team is also available to provide assistance.

A Ground Anchor Wall Construction Checklist is presented in Appendix K-6 to assist field personnel in preparing documents and inspecting fieldwork to ensure compliance with contract documents.

The contract specifications2 state the requirements for performance and proof testing of sub horizontal ground anchors. The record of readings from the performance and proof tests performed to verify the adequacy of the system shall be documented by the Contractor and provided to the Engineer. Structure Construction field personnel witness all performance and proof testing of the sub horizontal ground anchors.

11-2.2 Sequence of Construction

Sequence of sub horizontal ground anchor construction is as follows:

| SEQUENCE | DESCRIPTION |

| 1 | Drill the holes to the required length and diameter. |

| 2 | Install the prestressing steel unit. (Strands or Bar) |

| 3 | Place primary grout. |

| 4 | Complete performance and proof tests (refer to section on testing later in this chapter). |

| 4 | Complete performance and proof tests (refer to section on testing later in this chapter). |

| 5 | Lock-off and stress. |

| 6 | Place secondary grout. |

Note: Each step must comply with the contract specifications before proceeding to the next step.

11-2.3 Safety

Check the Contractor’s construction sequence against the authorized shop drawings. As excavation proceeds from the top down, look for signs of failure in the lagging or changes in the soil strata.

Sub horizontal ground anchors systems use powerful hydraulic rams to prestress or post- tension the system. Safety concerns are similar to those encountered with other prestressing operations. Structure Construction employees should not stand behind the hydraulic ram or cross it while stressing is taking place. The Prestress Manual and the SC Code of Safe Practices should be consulted for additional safety considerations.

11-3 Vertical Ground Anchors

Vertical ground anchors are similar to sub horizontal ground anchors although they act in the vertical plane. They can be used where site conditions do not allow traditional piles to achieve the necessary tensile capacity. For example, where rock exists close to the ground surface (or scour elevation), piles driven to refusal may be too short to develop sufficient skin friction to resist uplift or tensile loads required by the design. Vertical ground anchors are especially effective when combined with spread footings sitting directly on rock, or as part of a seismic retrofit strategy to add uplift capacity to a footing.

A schematic of a prestressing bar vertical ground anchor for a retrofit application is shown in Figure 11-2. Refer to Bridge Standard Detail Sheets (XS) 12-030-1 and 12-030- 2 for vertical ground anchor details.

The Contractor is responsible for providing the vertical ground anchor system that conforms to the design requirements shown on the contract plans and the testing requirements specified in the contract. After selecting a vertical ground anchor system, the Contractor sends the shop drawings and calculations to Structure Design, Documents Unit, for distribution, review, and authorization similar to the process outlined above for sub horizontal ground anchors.

The record of readings from the performance and proof tests must be documented by the Contractor and provided to the Engineer. Structure Construction field personnel witness all performance and proof testing of the vertical ground anchors.

11-3.1 Sequence of Construction

Sequence of vertical ground anchor construction is as follows:

| SEQUENCE | DESCRIPTION |

| 1 | Drill the hole the required depth and diameter. |

| 2 | Install the prestressing strands or bar. |

| 3 | Place primary grout. |

| 4 | Complete performance and proof tests (refer to section on testing later in this chapter). |

| 5 | Lock-off and stress. |

| 6 | Place secondary grout. |

Note: Each step must comply with the contract specifications before proceeding to the next step.

11-4 Testing of Ground Anchors

Ground anchors require testing of the in-place anchors. Performance tests are done on a predetermined number of anchors, and proof tests are required on all of the remaining anchors. If the test results indicate that the anchors are not achieving capacity, additional monitoring and testing is required. If they do not pass at that point, a revision to the original design will be required. The redesign should be discussed with the Designer. The specific requirements for testing are provided in the contract specifications3, the following is a general explanation of the required tests.

-

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99 -

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00 -

Pile Driving (PDF Download)

$89.00

Pile Driving (PDF Download)

$89.00

-

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

-

Pile Driving (Book)

$89.00

Pile Driving (Book)

$89.00