Composite Pile Splices

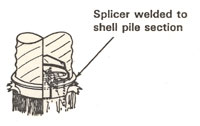

Although not widely used, the most common type of composite pile is a timber/corrugated shell pile. Timber is used for the major length of a pile, and then topped with a corrugated shell, which is later filled with concrete. A proprietary transition splice is available for use in this application. It’s upper end welds to the shell and lower “barbed end” is driven into the top of the timber pile.

Although not widely used, the most common type of composite pile is a timber/corrugated shell pile. Timber is used for the major length of a pile, and then topped with a corrugated shell, which is later filled with concrete. A proprietary transition splice is available for use in this application. It’s upper end welds to the shell and lower “barbed end” is driven into the top of the timber pile.

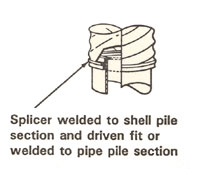

Like the timber/corrugated shell “combination” pile, a steel pipe/corrugated shell pile transition accessory for splicing pipe piles to shell piles is also available. The splicer is welded to the shell pile section

and then driven fit or welded to the pipe pile section. A steel monotube can be spliced to a steel pipe pile by welding a transition coupling to both sections.

Simple splicers can provide for connection from low-cost untreated timber piles to concrete-filled shell for use above the water table. The timber pile is driven to ground level. A shaped casting with “wedges” for driving into the wood is welded to uniform diameter shell. This is pulled up on a pipe as a mandrel and set on the timber pile. It is then driven as a unit to the desired depth. An expanding mandrel is not required. The pipe mandrel stays attached to the hammer and is removed. The shell is then filled with concrete when convenient.

Simple splicers can provide for connection from low-cost untreated timber piles to concrete-filled shell for use above the water table. The timber pile is driven to ground level. A shaped casting with “wedges” for driving into the wood is welded to uniform diameter shell. This is pulled up on a pipe as a mandrel and set on the timber pile. It is then driven as a unit to the desired depth. An expanding mandrel is not required. The pipe mandrel stays attached to the hammer and is removed. The shell is then filled with concrete when convenient.

Corrugated shell piles have a depth limit around 100 feet (the maximum length that can be installed with a practical height of leads.) Pipe can be driven first and spliced for penetration to any depth. A pipe-to-shell transition splicer provides for changing from pipe to lower cost shell for the depth it can reach. The splicer is gas welded to the shell and can have a drive-fit connection to the pipe for a quick, no-weld extension.

-

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99 -

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00 -

Pile Driving (PDF Download)

$89.00

Pile Driving (PDF Download)

$89.00

-

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

-

Pile Driving (Book)

$89.00

Pile Driving (Book)

$89.00