Chemical Grouting 101: Basics of Permeation Grouting for Soil Stabilization in Deep Foundations

Chemical grouting has become a critical ground improvement method for stabilizing loose and permeable soils in deep foundation construction. Among the various chemical grouting techniques, permeation grouting stands out for its ability to strengthen soil without disturbing existing ground conditions. Used widely beneath structures, around deep foundations, and in groundwater control applications, permeation grouting allows engineers to improve soil performance with precision and predictability using modern chemical grouting systems.

Understanding Chemical Grouting in Geotechnical Engineering

Chemical grouting is a ground improvement process where low-viscosity fluids are injected into soil to modify its engineering properties. Unlike mechanical densification methods, chemical grouting alters soil behavior by filling pore spaces with grout that later hardens, increasing strength and reducing permeability. This technique is commonly applied in sands, gravels, silts, and fissured soils where traditional compaction methods are impractical.

In deep foundation work, chemical grouting is often used to stabilize bearing strata, reduce settlement, and control groundwater prior to pile installation or excavation. The effectiveness of chemical grouting depends on soil gradation, grout viscosity, injection pressure, and the degree of control over the mixing process.

What Is Permeation Grouting?

Definition and Core Principles

Permeation grouting is a form of chemical grouting in which grout penetrates the voids between soil particles without disturbing the soil structure. The grout flows through existing pore spaces and bonds the soil grains together once cured. This method differs from compaction or fracture grouting, which intentionally displace or crack the ground.

The success of permeation grouting relies on using grouts with very low viscosity, often similar to water, allowing them to permeate granular soils under controlled pressures. Because the soil skeleton remains intact, surface movement and vibration are minimal, making permeation grouting suitable for sensitive or load-bearing environments.

Common Grout Types Used

Permeation grouting typically uses chemical grouts such as sodium silicate, acrylate, or polyurethane-based materials, depending on performance requirements. Cementitious grouts may also be used when ultra-fine particles are specified, though chemical grouts remain preferred for finer soils due to superior penetration capabilities.

Each grout type offers different curing times, strengths, and permeability reduction characteristics, allowing engineers to tailor the solution to site-specific needs.

Soil Conditions Suitable for Permeation Grouting

Granular Soils and Void Structures

Permeation grouting performs best in sands and gravels with sufficient interconnected voids. Uniformly graded soils allow grout to flow evenly, producing predictable results. The permeability of the soil must be high enough to accept grout without excessive pressure that could cause ground heave or fracturing.

Soil investigation data, including grain size distribution and permeability testing, play a critical role in determining feasibility. Fine silts and clays generally limit grout penetration and may require alternative ground improvement techniques.

Groundwater Considerations

Groundwater presence strongly influences permeation grouting design. Many chemical grouts are formulated to react and cure in wet conditions, making them effective for groundwater control. Grouting can significantly reduce hydraulic conductivity, helping prevent seepage beneath foundations, cofferdams, and excavation support systems.

Permeation Grouting Process in Practice

Injection Planning and Control

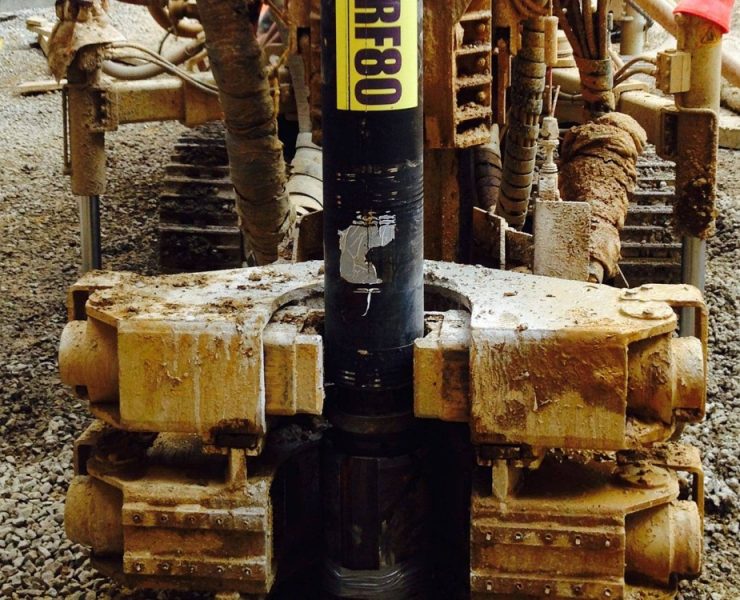

Permeation grouting begins with careful planning of injection points, spacing, and sequencing. Grout is injected at low pressures through sleeve pipes or drilled holes to ensure controlled distribution. Injection pressures are monitored closely to avoid soil displacement and to confirm that grout is flowing through pores rather than fracturing the ground.

Modern permeation grouting relies heavily on metered delivery and monitoring systems to maintain consistency throughout the process. This level of control is especially important when working around deep foundations or existing structures where tolerances are tight.

Curing and Performance Verification

After injection, the grout cures within the soil, forming a hardened matrix that increases strength and stiffness. Verification methods include permeability testing, coring, and load testing to confirm performance objectives have been met. Engineers often specify staged grouting programs to progressively improve soil conditions while monitoring results in real time.

Applications in Deep Foundation Construction

Foundation Support and Load Transfer

Permeation grouting is frequently used to improve bearing capacity beneath shallow and deep foundations. By increasing soil stiffness, the method enhances load transfer and reduces settlement risks. This is particularly valuable in rehabilitation projects where existing foundations require additional support.

Excavation and Underground Construction

In deep excavations, permeation grouting stabilizes soil and controls groundwater inflow, improving safety and constructability. The technique is commonly applied ahead of shaft construction, underpinning operations, and pile installations in water-bearing sands.

Permeation grouting is also widely used as a pre-treatment method, creating a stabilized zone that allows other construction activities to proceed more efficiently using specialized permeation grouting equipment.

Advantages and Limitations of Permeation Grouting

Key Benefits

One of the primary advantages of permeation grouting is its non-disruptive nature. Because soil structure remains intact, surface movement is minimal, and vibration-sensitive structures are protected. The technique also provides precise control over strength gain and permeability reduction, making it well suited for complex geotechnical challenges.

Practical Constraints

Despite its advantages, permeation grouting is not universally applicable. Soil conditions must be suitable, and material costs can be higher than traditional methods. Proper design, testing, and quality control are essential to achieving predictable outcomes.

Role of Modern Grouting Technology

Advances in monitoring, mixing, and delivery technology have significantly improved the reliability of permeation grouting. Automated systems allow for precise control of grout ratios, flow rates, and injection pressures, resulting in more consistent soil improvement. These innovations continue to expand the range of projects where permeation grouting can be applied safely and effectively.

Permeation grouting remains a cornerstone technique for soil stabilization in deep foundation construction, offering a controlled and non-intrusive solution for improving ground performance. When designed and executed properly, it enhances bearing capacity, reduces settlement, and manages groundwater without disturbing existing soil structures. As grouting technology continues to evolve, permeation grouting will remain a vital tool for engineers addressing complex geotechnical conditions in modern foundation projects.

It stabilizes loose soils and reduces permeability beneath foundations without disturbing existing soil structure.

Permeation grouting works best in granular soils like sands and gravels with interconnected voids. What is permeation grouting used for in construction?

Which soils are suitable for permeation grouting?