Best Practices for Auger and Bit Selection in Environmental Drilling for Construction Sites

Environmental drilling plays a critical role in construction projects where understanding subsurface conditions is essential for site planning, regulatory compliance, and safety. Choosing the right auger and bit combination is foundational to collecting reliable soil samples, installing monitoring wells, and assessing groundwater conditions. With soils ranging from soft silts to dense clays and mixed debris, environmental drilling requires careful planning of both auger style and bit profile to maximize efficiency and data integrity. To help professionals improve drilling outcomes on construction sites, this article explores how soil characteristics, drilling goals, and bit design affect tool selection and drilling performance.

Understanding Environmental Drilling Objectives

What Environmental Drilling Entails

Environmental drilling is a specialized form of subsurface investigation used to collect soil and groundwater samples, install monitoring wells, and evaluate contamination at construction sites. Unlike deep foundation drilling, environmental drilling typically focuses on obtaining representative soil data, documenting stratigraphy, and identifying contaminants with minimal disturbance to the ground. Auger drilling is one of the most widely used techniques in these applications because it is efficient in many soil conditions and does not require drilling fluids that could interfere with sample integrity. This method involves a helical screw bit that advances into the ground, lifting cuttings to the surface as it rotates, and allows for soil sampling up to moderate depths in suitable geologies such as sand, silt, and clay.

Linking Project Goals to Equipment Needs

Before selecting an auger or bit, it is important to define the goals of the drilling project. For environmental assessments, ensuring that samples are not contaminated or overly disturbed is a priority. Soil type, desired depth, and the presence of groundwater all inform the choice of tooling. For example, in construction sites with known soft soils, augers that maintain borehole stability and allow continuous soil extraction are valued. Contractors should also consider how the drilling approach integrates with laboratory analysis requirements and regulatory standards for environmental characterization.

Auger Types and Their Roles in Environmental Drilling

Hollow Stem Augers for Sample Integrity

Hollow stem augers are especially favored in environmental drilling because their central shaft allows soil cores to be extracted without removing the auger from the hole. This feature reduces the risk of sample contamination and disturbance, which is critical for accurate chemical and geotechnical profiling. The hollow design also facilitates the installation of well casings during the same drilling operation, making it a practical choice for groundwater monitoring and long-term site assessment.

Continuous Flight Augers for Soft Soils

Continuous flight augers consist of a solid, spiraling flight that conveys cuttings upward as the auger advances. These tools work well in softer soil profiles where hole stability is easier to maintain, and they are often chosen when the project requires consistent penetration through silt, loam, or loose sand. Continuous flight augers help maintain a steady drilling rhythm and make it easier to adjust drilling parameters quickly as conditions change, which is common on construction sites with heterogeneous soils.

Auger Selection Based on Soil Conditions

Soil composition directly influences which auger type will provide the best performance. In highly cohesive soils like clay, augers need to work at speeds and with cutting profiles that prevent material from packing around the flights and slowing progress. In contrast, sandy and granular soils respond well to auger designs that efficiently remove loose material without excessive vibration or torque. Multiple auger types might be used sequentially on a single site when subsurface conditions vary, making it important for drilling crews to have a range of tooling available and to adjust strategies based on real-time observations.

Drill Bit Selection for Environmental Drilling Scenarios

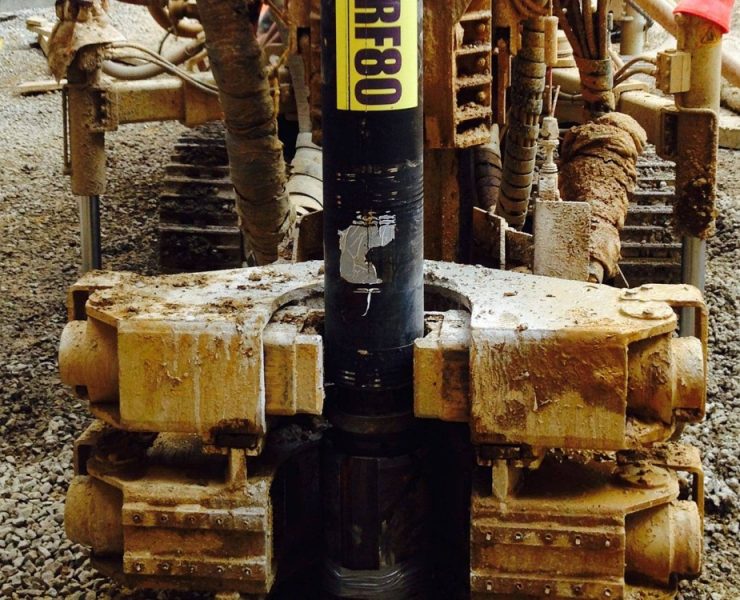

Matching Bits to Subsurface Materials

Drill bits serve as the cutting interface between the drilling rig and the subsurface formations. In environmental drilling, the goal is often to cut through unconsolidated material like soil with minimal sample disruption, rather than to bore through hard rock. Bits designed for soil drilling typically feature cutting edges that balance penetration with smooth removal of material to prevent clogging and maintain sample integrity. Using the right bit profile for specific soil textures reduces wear and tear on equipment and improves the quality of recovered material.

Durability and Compatibility Considerations

Bits must be durable enough to handle the mechanical stresses of drilling while avoiding damage that could compromise sample quality. Selecting bits made from wear-resistant materials and designed to fit the drill string and auger assembly being used ensures compatibility and reduces downtime. Construction site conditions are dynamic, and crews should be ready to switch bit types as they encounter more dense or abrasive soils. Choosing bits that align with the power and torque characteristics of the drilling rig also helps maintain progress without overloading equipment.

Operational Practices for Better Drilling Outcomes

Pre Drill Soil Assessment

Conducting a soil investigation before drilling begins allows the team to forecast potential challenges and select augers and bits that match the anticipated conditions. Soil borings and historic site data can inform tooling decisions, reducing the likelihood of unsuitable equipment slowing the project. These advance assessments also help identify layers where groundwater might be encountered or where soil transitions could require adjustments in drilling approach.

Real Time Monitoring and Skillful Adjustments

Even with thorough pre-drill planning, actual subsurface conditions can differ from expectations. Skilled drill operators monitor drilling rates, torque feedback, and cuttings characteristics to determine when auger type or bit choice should change. Making these adjustments in real time improves the quality of soil samples and prevents unnecessary delays caused by tool wear or inefficient drilling.

Sustainability and Safety in Drilling Practices

Minimizing Environmental Disturbance

A priority in environmental drilling is to minimize the impact of drilling operations on the surrounding area. Using augers and bits that reduce soil disturbance helps maintain site integrity and reduces the risk of contaminant spread. Selecting tools that support efficient drilling with minimal fluid use also aligns with environmental protection goals at construction sites.

Worker Safety and Equipment Maintenance

Appropriate tooling not only enhances drilling outcomes but also contributes to safer job sites. Proper bit selection prevents unexpected equipment failures that could endanger operators. Routine maintenance of auger flights and bits ensures optimal performance throughout the project.

Maximizing Performance with Informed Tooling Choices

Selecting the best auger and drill bit for environmental drilling at construction sites requires an understanding of soil conditions, project goals, and tooling characteristics. By evaluating soil profiles, using auger types suited to site conditions, and matching drill bits carefully to subsurface materials, contractors can improve drilling efficiency and sample quality. When operators combine careful tool selection with adaptive practices in the field they can deliver reliable results that support project timelines and environmental compliance. Thoughtful preparation and informed choices in auger and bit selection ultimately contribute to safer, more predictable drilling operations and better outcomes for construction site investigations.

Different auger types maintain borehole stability and protect sample integrity in varying soil conditions.

Proper bit selection reduces soil disturbance, prevents clogging, and ensures accurate sample recovery. Why are auger types important in environmental drilling?

How do drill bits affect soil sampling quality?