Timber Pile Splices

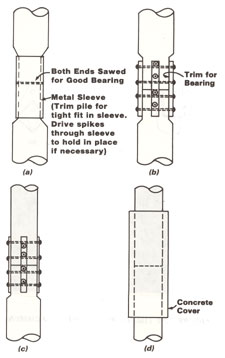

Although timber piles have been spliced, the practice is not encouraged. Timber pile splices are generally undesirable as it is virtually impossible to develop the full bending strength of the piling through simple splices such as those shown. In order to develop full bending strength, a detail similar to that shown is required. However, there are obviously job conditions encountered where the situation will arise.

Although timber piles have been spliced, the practice is not encouraged. Timber pile splices are generally undesirable as it is virtually impossible to develop the full bending strength of the piling through simple splices such as those shown. In order to develop full bending strength, a detail similar to that shown is required. However, there are obviously job conditions encountered where the situation will arise.

When timber piles have been spliced prior to driving, they are generally bolted on with the use of timbers or steel plate. Bolt holes should be drilled at least 1/16 in. less than bolt diameter and through the entire assembly so they will fit tightly. If the splice will be above permanent ground water special provision must be made for wood preservation. This type of splice is seldom used.

A more common splice for timber is a pipe with interior wedges, installed after a length of timber is driven. The pile head is shaped to the pipe splice size and an additional length added. Again, provision must be made for preservation of the wood if the cut ends are above permanent ground water level.

Timber piles require care in splicing, partly because of difference in size between the butt of the driven section and the tip of the added section. Bolted timber lagging requires accurate shaping of both sections of pile and tight attachment.

Splicing timber piles should be avoided if practical. Splicing can be done but is expensive and time consuming. A better solution to extension might be a composite pile.

-

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99 -

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00 -

Pile Driving (PDF Download)

$89.00

Pile Driving (PDF Download)

$89.00

-

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

-

Pile Driving (Book)

$89.00

Pile Driving (Book)

$89.00