How Hammer Grabs Improve Efficiency in Bore Pile Construction

Bore pile construction demands accuracy, power, and consistency. Every second on site counts, and each movement of equipment can affect the structural integrity of the finished foundation. That’s why the industry continues to evolve with machinery designed for faster, cleaner, and safer excavation.

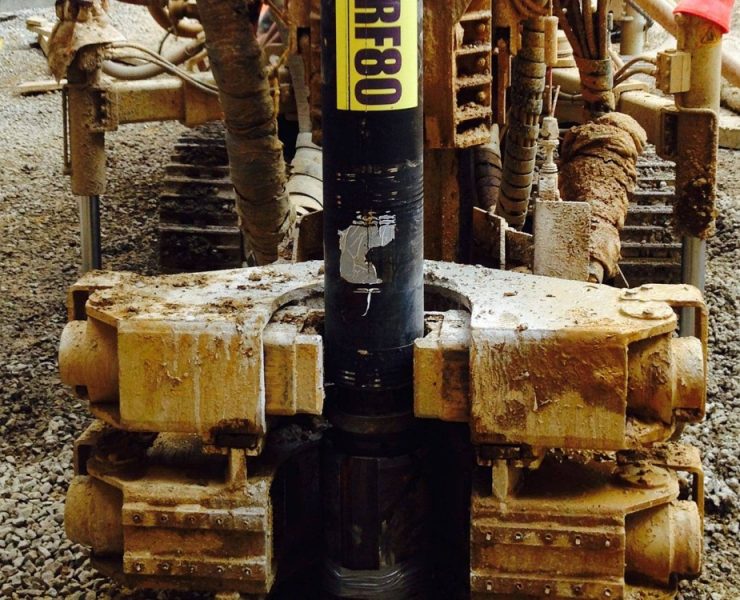

Among these innovations, the hammer grab has become a key player in deep foundation and bore pile work. Its ability to efficiently remove loose soil, sand, and gravel from drilled shafts has made it indispensable on sites where precision and reliability are non-negotiable.

What Makes Hammer Grabs Essential in Bore Pile Construction

The hammer grab operates by lowering into the casing pipe, grabbing loosened material, and lifting it out — allowing clean, controlled excavation inside the borehole. This process is critical in under bore pile construction or all-casing methods, where precision and speed must go hand in hand.

Unlike conventional drilling buckets or augers, a hammer grab relies on mechanical free-fall excavation. The tool drops by gravity, strikes the material, and closes its jaws to capture debris efficiently. This simple yet effective motion drastically reduces the time needed for each excavation cycle.

By maintaining consistent removal rates across a variety of soil types — particularly sand and gravel — it ensures that the pile shaft remains clear, stable, and ready for the next construction phase.

Aerodynamic Design for Faster Drilling

Efficiency begins with design. A defining feature of the modern hammer grab is its streamlined shape, engineered to minimize water resistance. This not only helps it descend quickly but also ensures smooth operation in saturated or unstable soils.

The aerodynamic body allows for faster drilling and reduced friction, improving cycle time and lowering energy consumption. Each drop becomes more productive, and the cumulative time saved over dozens of cycles can significantly shorten project timelines.

Contractors using this equipment often report enhanced drilling performance even in challenging ground conditions — especially when alternating between sandy, silty, and gravelly layers.

Built to Withstand the Toughest Conditions

A bore pile site is no place for fragile equipment. To handle repetitive high-impact work, the hammer grab is built from high-strength, abrasion-resistant steel. The use of hardened materials, such as HARDOX at the jaw ends, provides exceptional durability against constant wear and impact.

This ensures the tool retains its cutting and gripping performance throughout long project cycles. The strong closing force of the jaws allows it to penetrate and lift dense or compacted material without slippage, improving load efficiency with each grab.

In the long run, this resilience means fewer breakdowns, fewer part replacements, and ultimately lower maintenance costs — all of which contribute to greater overall productivity.

Reducing Maintenance with Smarter Engineering

One of the most overlooked contributors to job-site efficiency is maintenance downtime. Modern hammer grab designs address this by incorporating closed pulleys filled with oil, ensuring continuous lubrication and minimal friction.

This innovation drastically reduces the frequency of maintenance checks and extends the lifespan of wire ropes — components that otherwise demand regular attention in high-use environments.

Moreover, convertible parts allow operators to easily modify or replace key components when switching between different casing diameters or soil types. This modular design cuts service time and helps crews adapt to new site conditions without additional machinery.

The result is a tool that stays in the field longer, works harder, and requires less unproductive downtime in the shop.

Single Rope vs. Double Rope Systems

Efficiency isn’t only about speed — it’s also about control. Different bore pile conditions call for different operation systems, and the hammer grab delivers both.

The Single Rope Operation System provides simple, user-friendly handling. It’s ideal for everyday excavation tasks, minimizing operator error while maintaining steady performance. For smaller bore diameters or shallow projects, this configuration ensures consistency without the need for complex adjustments.

Meanwhile, the Double Rope Operation System brings power and precision to large-diameter or underwater work. Its dual-line mechanism provides greater balance and stability, especially during free-fall impact. This not only increases excavation efficiency but also reduces the stress on casing walls and surrounding soil, making it suitable for sensitive or high-value projects.

By switching between these systems depending on the job, contractors can fine-tune performance to maximize both speed and safety.

Efficiency in Sand and Gravel Layers

Few ground conditions are as unpredictable as sand and gravel. These materials tend to shift, collapse, or clog during drilling, making excavation challenging for traditional equipment.

The hammer grab overcomes these challenges through its strong closing pressure and minimal drag design. It effectively collects loose, flowing material without spillage — even when submerged in water. The precise jaw alignment ensures complete closure, preventing soil loss during lifting.

In addition, its quick-release system allows the jaws to open and discharge material efficiently, ensuring smooth transitions between excavation cycles. The combination of these factors keeps the borehole clear and stable, maintaining consistent progress without interruptions.

This reliability makes the tool a preferred choice in projects such as bridge foundations, harbor walls, and high-rise construction, where bore piles must be excavated rapidly under challenging geological conditions.

The Economics of Efficiency

Contractors know that every improvement in cycle time or durability has a direct impact on profitability. Modern hammer grab systems offer measurable economic benefits — from reduced wear on auxiliary machinery to lower fuel and labor costs.

By maintaining high excavation rates and minimizing downtime, crews can complete bore pile drilling faster, move on to concrete placement sooner, and keep overall project timelines under control.

These gains are amplified in large-scale operations, where hundreds of piles may be installed. Even a 10% increase in efficiency per pile can translate to weeks saved across the entire project, along with substantial cost reductions in manpower and maintenance.

Toward Smarter, Sustainable Drilling

Today’s bore pile projects are not only about strength but also sustainability. Equipment that lasts longer and consumes less energy contributes to lower carbon footprints on construction sites.

The hammer grab supports this shift by offering optimized mechanical efficiency — achieving more excavation with less power and fewer emissions. Its replaceable components and extended service life reduce waste, aligning with the industry’s move toward greener construction practices.

Bore pile construction is a precise science — and the right equipment can determine the success of a foundation from the very first meter. The evolution of the hammer grab embodies this principle, blending strength, speed, and simplicity to create a tool that performs flawlessly in even the toughest environments.

From streamlined designs that cut through water and sand to durable jaws that stand up to years of impact, every element of modern hammer grab technology is engineered for efficiency. For contractors seeking dependable performance in deep foundation work, this innovation continues to set the standard for how excavation should be done — faster, cleaner, and smarter.

Hammer grabs efficiently remove loose soil, sand, and gravel from drilled shafts to ensure precise and stable bore piles.

Their streamlined design, durable jaws, and modular systems reduce excavation time, maintenance, and downtime. What is a hammer grab used for in bore pile construction?

How do hammer grabs improve efficiency on construction sites?