Essential Maintenance Practices for Wire Ropes in Over-Water Crane Operations

Operating cranes over water places exceptional demands on wire ropes. Constant exposure to moisture, salt spray, fluctuating temperatures, and dynamic loading conditions accelerates wear mechanisms that may remain hidden until a critical failure occurs. In marine construction, where cranes often handle heavy loads over open water, wire rope maintenance is not just a reliability concern but a fundamental safety requirement. Understanding how environmental factors affect wire rope performance is essential for maintaining lifting integrity and preventing unplanned downtime.

Over-water crane operations introduce corrosion, fatigue, and abrasion risks that are significantly more severe than those encountered in land-based lifting. Even well-designed lifting systems can experience rapid degradation if inspection and maintenance practices are not adapted to marine conditions. Applying disciplined maintenance practices helps extend service life, supports regulatory compliance, and reduces the likelihood of sudden wire rope failure during critical lifts.

Environmental Stressors in Marine Lifting

Corrosion Exposure in Saltwater Environments

Saltwater exposure is one of the most aggressive contributors to wire rope deterioration. Chloride ions penetrate protective coatings and lubricants, accelerating corrosion at both the surface and internal wire levels. Even freshwater environments present corrosion risks due to constant moisture and oxygen availability. Over time, corrosion reduces metallic cross-section, weakens individual wires, and compromises overall rope strength.

Corrosion often initiates internally, particularly in multi-strand ropes where moisture becomes trapped between wires. These hidden corrosion mechanisms are difficult to detect without targeted inspection techniques, making routine evaluation of marine lifting wire rope conditions essential in over-water crane operations.

Cyclic Loading and Fatigue Damage

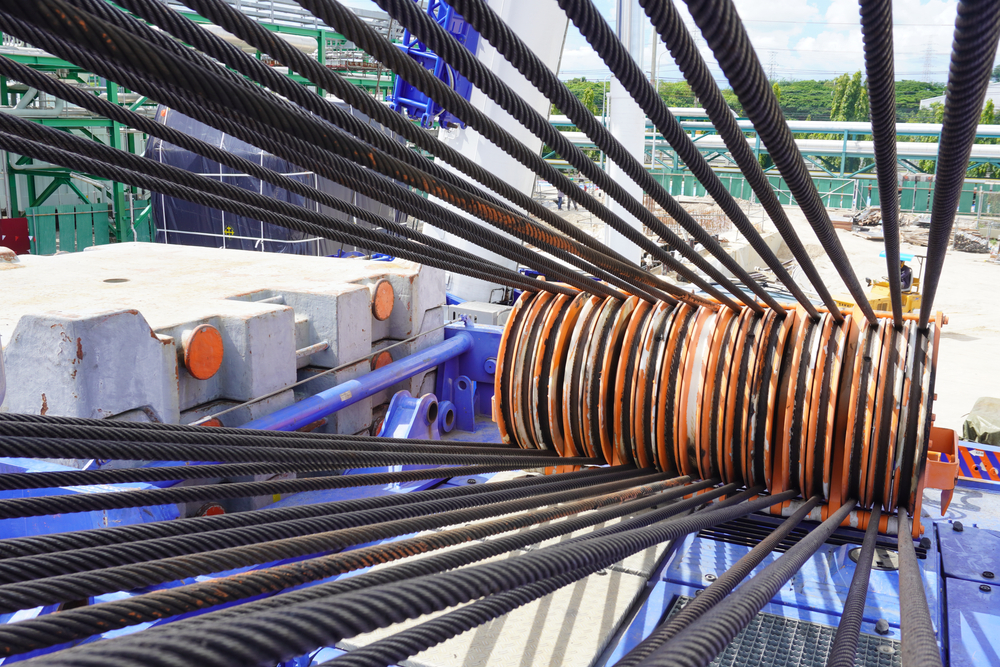

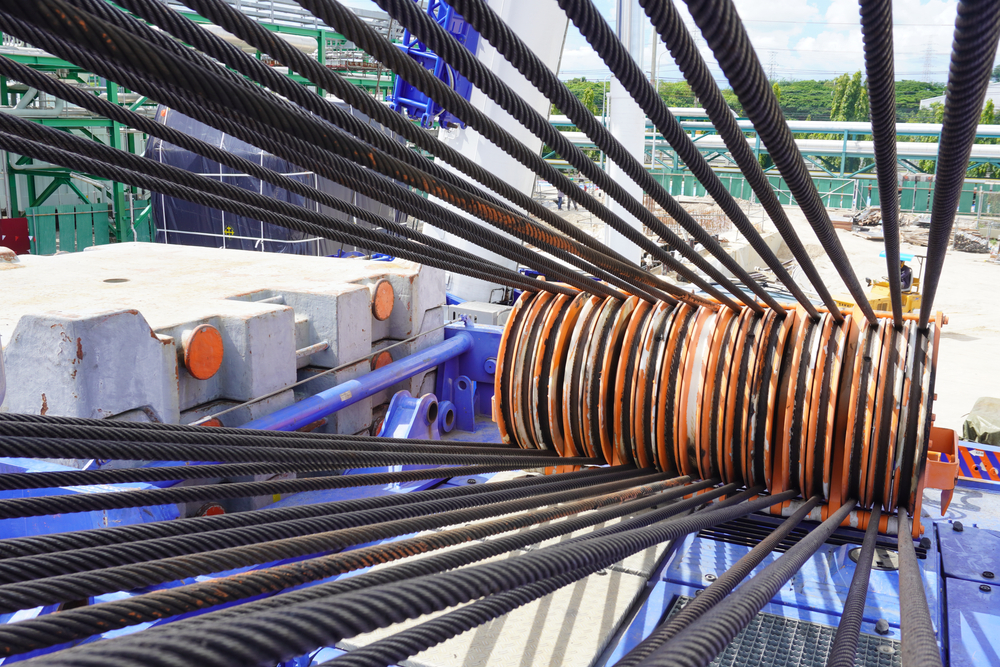

Wire ropes used in crane applications experience repeated bending over sheaves, drums, and fairleads. In over-water operations, these cycles are frequently combined with variable loads influenced by wave action, wind, and vessel movement. The resulting stress reversals accelerate fatigue damage, particularly at points where the rope bends under load.

Fatigue-related wire breaks tend to develop progressively and may cluster in localized areas. Without consistent monitoring, fatigue damage can advance to a critical stage before visible warning signs appear, increasing the risk of sudden failure during lifting operations.

Inspection Protocols for Over-Water Cranes

Visual Inspection Best Practices

Routine visual inspections remain the first line of defense in identifying wire rope deterioration. Inspectors should examine the full length of the rope where practical, paying close attention to high-stress zones such as termination points, sheave contact areas, and sections exposed to standing water. Indicators such as broken wires, corrosion pitting, flattened strands, or distorted rope geometry require immediate evaluation.

Visual inspections should be performed under adequate lighting and, when possible, with the rope unloaded to reveal internal deformation. For marine operations, inspection frequency typically increases due to accelerated environmental wear. Many operators integrate guidance from industry references on wire rope inspection standards to ensure inspection intervals align with operating conditions.

Advanced Inspection Techniques

Visual inspection alone may not detect internal corrosion or wire breaks hidden beneath the rope surface. Non-destructive testing methods, such as magnetic flux leakage inspection, are often used in critical crane applications to assess internal wire condition. These techniques provide quantitative data on metal loss and internal damage, supporting more informed maintenance decisions.

Advanced inspections are particularly valuable for ropes used in continuous over-water service, where replacement planning must balance safety considerations with operational demands. Incorporating periodic non-destructive testing improves confidence in wire rope integrity and reduces the likelihood of unexpected failures.

Lubrication and Protective Measures

Role of Lubrication in Marine Conditions

Lubrication plays a critical role in protecting wire ropes against corrosion and wear. Proper lubrication reduces friction between individual wires, minimizes internal abrasion, and creates a barrier against moisture intrusion. In marine environments, lubricants must be selected for resistance to washout and compatibility with saltwater exposure.

Re-lubrication intervals should account for environmental severity, rope usage frequency, and observed lubricant condition. Inadequate lubrication accelerates internal wear and corrosion, even when the rope appears acceptable externally. Consistent lubrication practices significantly extend service life in over-water crane applications.

Protective Coatings and Handling Practices

Beyond lubrication, protective measures such as galvanized wires or specialized coatings help resist corrosion in marine environments. However, coatings alone do not eliminate the need for inspection and maintenance. Improper handling, such as dragging ropes across abrasive surfaces or allowing them to sit submerged when not in use, can damage protective layers and accelerate deterioration.

Good handling practices include proper spooling on drums, maintaining correct fleet angles, and avoiding shock loading during lifts. These operational controls reduce mechanical damage and complement lubrication and inspection efforts.

Storage and Operational Controls

Storage Considerations Between Operations

Wire ropes used intermittently in over-water crane operations require careful storage when not in service. Storing ropes in dry, well-ventilated conditions reduces corrosion risk and preserves lubricant effectiveness. When onboard storage is unavoidable, ropes should be protected from standing water and shielded from direct exposure to spray whenever possible.

Periodic rotation of stored ropes helps redistribute lubricant and prevents localized corrosion. Storage practices often receive less attention than active maintenance, yet they play a significant role in long-term wire rope performance.

Load Management and Operational Discipline

Operational discipline directly influences wire rope longevity. Avoiding overloads, minimizing side loading, and maintaining smooth lifting motions reduce stress concentrations within the rope. Over-water lifts frequently involve dynamic conditions, making precise load control and communication essential.

Operators who align lifting procedures with established marine crane safety practices reduce the cumulative fatigue imposed on wire ropes. These practices support both safety outcomes and asset preservation in demanding marine environments.

Replacement Criteria and Lifecycle Planning

Recognizing End-of-Service Indicators

Wire rope replacement decisions should be based on measurable condition indicators rather than arbitrary service intervals. Excessive broken wires, significant corrosion, diameter reduction, or deformation typically signal that a rope has reached the end of its safe service life. In marine operations, replacement thresholds may be more conservative due to the elevated consequences of failure.

Documenting inspection findings over time supports trend analysis and proactive replacement planning. This approach reduces reliance on reactive decisions made under operational pressure.

Integrating Maintenance into Project Planning

Effective wire rope maintenance extends beyond individual inspections and repairs. Integrating maintenance planning into project schedules ensures that inspection, lubrication, and replacement activities occur without disrupting critical lifts. For long-duration marine construction projects, lifecycle planning helps balance safety, cost, and operational continuity.

By adopting structured maintenance strategies informed by industry experience and operational data, contractors can improve reliability while minimizing unexpected downtime. Reference materials related to wire rope maintenance for marine cranes often emphasize the importance of aligning maintenance practices with environmental exposure and usage patterns.

Closing Considerations for Over-Water Operations

Wire ropes used in over-water crane operations operate in one of the most demanding lifting environments in construction. Exposure to moisture, salt, and dynamic loads accelerates wear mechanisms that require vigilant inspection, disciplined lubrication, and thoughtful operational controls. Relying solely on visual condition or service age is insufficient when environmental stressors actively degrade rope integrity.

A comprehensive maintenance approach that combines routine inspection, advanced testing, proper lubrication, and informed replacement planning significantly reduces the risk of failure. As marine construction projects grow in scale and complexity, consistent attention to wire rope condition remains a cornerstone of safe and efficient crane operations.