Revitalizing Anabel Basin: Strengthening New York’s Maritime Hub with SPiRe®+ Innovation

Anabel Basin: A Strategic Maritime Hub for New York

Anabel Basin, situated along New York’s extensive waterfront, plays a critical role in supporting the state’s economy and infrastructure. As a key entry point for cargo, vessels, and logistics operations, the basin is integral to facilitating the movement of goods essential to New York City and its surrounding areas. It serves both as a protective barrier against coastal erosion and as a support structure for piers, docks, and other marine operations, making it invaluable for local businesses and industries reliant on waterfront access.

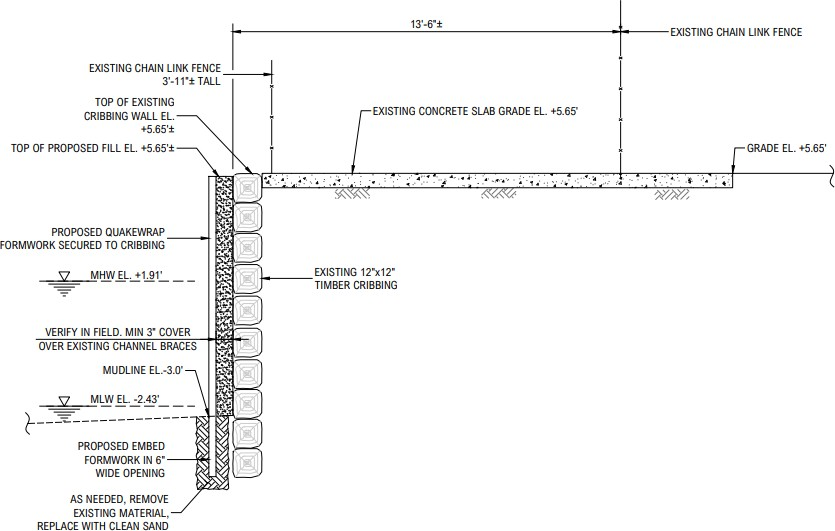

The client report details a comprehensive timeline of repairs, wherein six sections of the blocks in basin facility underwent structural assessment. Initial inspections conducted in September 2018 classified one section as serious, one as poor, and two as critical. A follow-up survey in February 2021 revealed that these four sections had all deteriorated to a critical condition, highlighting the immediate necessity for structural intervention to restore and stabilize the facility.

The seawall in question had sustained severe damage due to prolonged exposure to environmental elements, resulting in notable rot and deterioration. Some timber elements were missing or broken, which left the structure compromised. In certain sections, soil beneath the deck had washed away, forming cavities that further weakened the foundation and contributed to instability along the wall. These conditions not only reduced the seawall’s effectiveness in protecting the shoreline but also posed a risk of erosion and property damage. There is no standard method for repairing corroded seawalls. In cases of severe steel loss, new steel plates may be welded to the damaged sections, but underwater welding is costly and difficult to permit. Additionally, the unprotected steel remains vulnerable to future corrosion.

Another approach is to clean the rust and apply a corrosion-inhibiting paint, which blocks oxygen and water to slow corrosion. However, this requires costly coffer dam construction for access, especially in deep water. Moreover, the coating’s durability is limited—once it cracks, corrosion resumes as water and oxygen seep in.

ǪuakeWrap Innovative Repair Techniques and Material Selection

The scope of work for the Anable Basin Bulkhead Stabilization project involved several key techniques to restore and enhance the shoreline infrastructure. First, partial demolition of the existing timber and concrete bulkheads targeted areas compromised by decades of exposure and deterioration. This was followed by the installation of new stone revetments to absorb wave energy and stabilize the shoreline, as well as concrete retaining walls that add resilience by preventing soil erosion.

To improve accessibility for inspection and maintenance, a structural steel catwalk designed for a high live load of 125 psf was installed, offering durability against environmental stresses.

SPiRe®+: The Optimal Solution for Marine Projects

ǪuakeWrap‘s newest innovation, the SPiRe®+ panels, addresses traditional repair challenges with cutting-edge efficiency. Crafted through a pultrusion process that combines glass fabric and resin, these panels form a thin yet durable laminate, bringing notable improvements over conventional FRP methods:

• Minimal Surface Preparation: Panels adhere well to rough surfaces, significantly reducing preparation time.

• Underwater Application: Designed for underwater use, these panels are a breakthrough for marine infrastructure repairs.

Applications and Benefits of SPiRe®+ Panels in Anable Basin

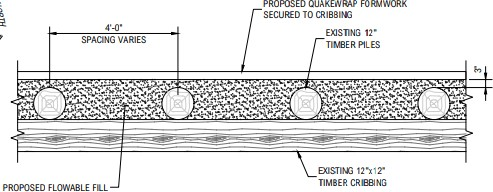

The panels are bolted onto corroded structures, creating an annular space filled with cementitious or epoxy grout. Flexural tests indicate that SPiRe®+ panels deliver reinforcement comparable to #6 Grade 60 steel bars, providing an efficient alternative to traditional steel reinforcements.

The exterior face of the panels is flat and smooth. The interior face has protruding T profiles. That face is also grit coated for improved bonding to concrete. Together, the flat panel and the T profiles act as reinforcing bars for strengthening the seawall repair.

Formwork was utilized to shape the new concrete sections, while flowable fill was placed to fill voids behind the timber bulkhead, providing lightweight support under the deck without excessive load. To align with New York environmental standards, advanced erosion and sediment control measures, including turbidity curtains, were implemented to minimize construction impact on the aquatic environment.

Transform Your Marine Infrastructure with Sustainable, Cost-Saving Solutions

For a wide range of marine projects—from seawalls and decks to bulkheads, piers, and docks—ǪuakeWrap’s SPiRe®+ panels offer an innovative, sustainable solution. These panels reduce costly preparation and eliminate the need for underwater welding, providing corrosion-resistant strength for various applications. By choosing SPiRe®+ panels, clients can enhance durability and performance across diverse structures, ensuring long-term resilience while minimizing environmental impact. Explore how our advanced technologies can bring cost-effective, reliable repairs and upgrades to your essential marine assets.