Repair of Corroded Steel Sheet Piles at Weston Pump Stations Using the SPiRe®+ System

Introduction

Like many municipalities in South Florida, the City of Weston faces the recurring challenge of managing large volumes of stormwater during heavy rainfall events. Stormwater is first stored in manmade lakes distributed throughout the community. When water levels exceed safe capacity, it is pumped through designated pump stations into a network of canals that eventually discharge into the Everglades.

The proper functioning of these pump stations is critical not only for flood protection but also for safeguarding public infrastructure, residential neighborhoods, and the surrounding ecosystem. Over time, however, the sheet pile walls that form part of the pump station structures had deteriorated severely. This case study describes how the City of Weston successfully rehabilitated two pump station seawalls using the innovative Sheet Pile Repair (SPiRe®+) system, an FRP-based solution developed and patented by Professor Mo Ehsani at QuakeWrap, Inc.

Problem Statement

The original walls at the pump stations were constructed using steel sheet piles. Constant exposure to alternating wet and dry conditions, combined with Florida’s aggressive environment, led to significant corrosion. In many areas, the section loss of the steel was so advanced that large perforations had formed, creating both structural and operational risks.

The city was faced with several pressing concerns:

- Structural integrity: Advanced corrosion compromised the walls’ load-bearing capacity, threatening long-term performance.

- Operational reliability: Loss of containment around the pumps could undermine the system’s ability to manage flood events.

- Environmental risk: Continued degradation could release rust and debris into stormwater discharges.

- Replacement cost: Driving new sheet piles in front of the existing walls was not feasible due to tight site constraints and high costs.

An alternative rehabilitation method was needed—one that could restore strength, provide a durable protective barrier, and be installed within the limited access conditions of the pump stations.

The SPiRe®+ System

To meet these challenges, the City selected the SPiRe®+ system, an advanced composite repair solution.

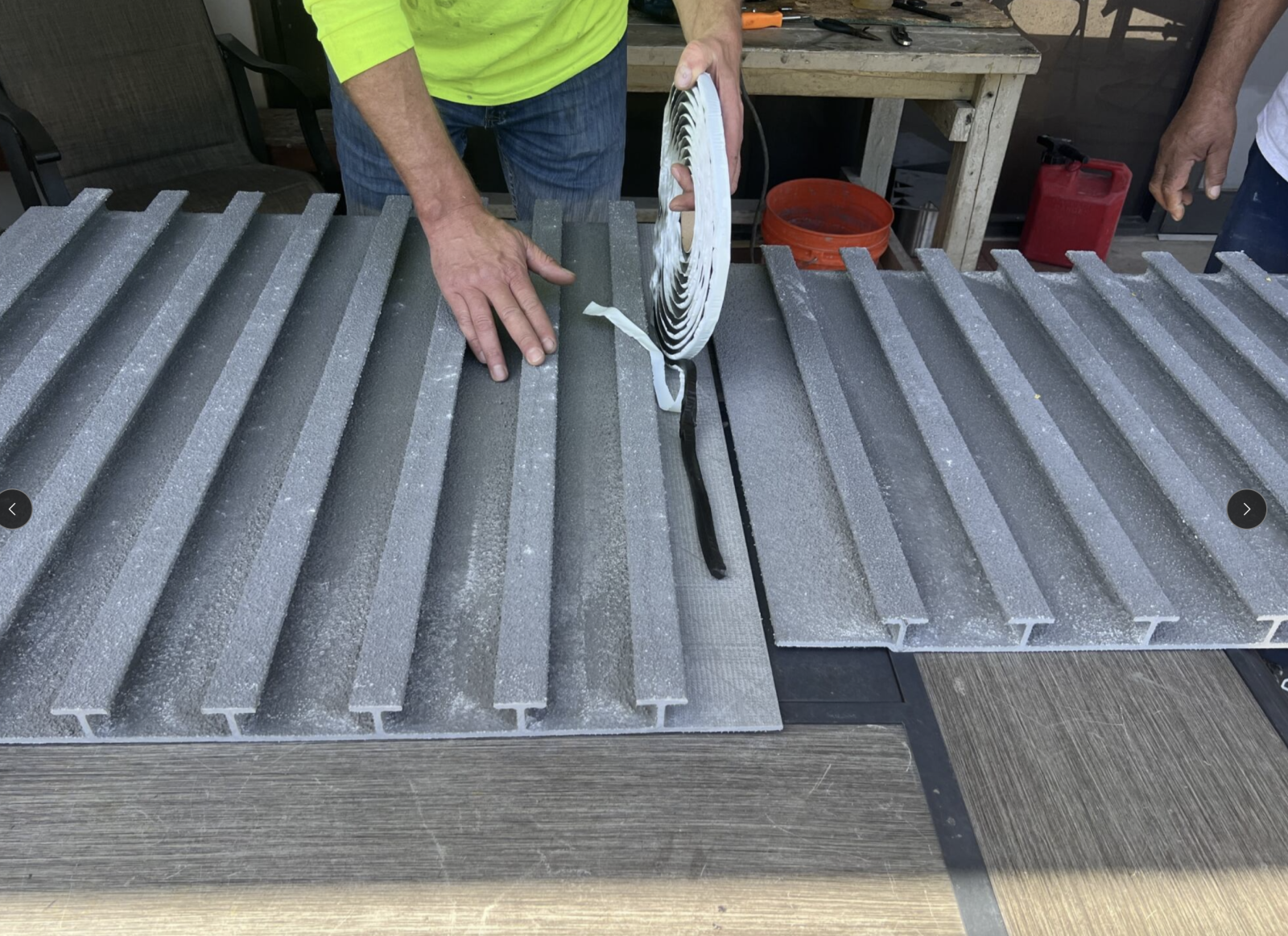

Each SPiRe®+ panel is a high-strength fiberglass laminate with integrally molded T-shaped ribs. These ribs act like built-in reinforcing bars, giving the panels exceptional flexural capacity. Independent testing has shown that the reinforcement provided is equivalent to No. 6 Grade 60 steel bars spaced at approximately 3.5 inches.

Additional features include:

- Grit-coated surfacesto enhance bonding with concrete.

- Light weightfor easy handling in tight spaces.

- Field adaptability, allowing panels to be cut to size for penetrations or pump openings.

- Prefabricated corner piecesavailable at 90° and 135° angles for geometric transitions.

- Impervious barrierproperties, preventing moisture and oxygen from reaching the underlying steel.

Together, these attributes make SPiRe®+ particularly well suited for rehabilitating corroded steel structures in water environments.

Installation Process

The repair work at Weston’s pump stations followed a carefully sequenced procedure:

- Wall preparation

Holes were cut into the existing corroded steel sheet piles using torches. This allowed for installation of new mechanical anchors. - Anchorage

J-bolts were secured into the wall at regular spacing, providing anchor points for the SPiRe®+ panels. - Panel installation

Three-foot-wide SPiRe®+ panels were lifted into position and mounted onto the J-bolts. Overlapping joints between adjacent panels were sealed with marine-grade sealant to ensure watertightness. Panels were then secured using self-tapping screws, creating a continuous impervious barrier over the corroded steel. - Dual-sided protection

In particularly deteriorated areas, panels were installed on both the front and back faces of the sheet pile wall. This effectively “sandwiched” the corroded steel between two composite layers, adding redundancy and strength. - Corners and openings

Field crews cut panels as needed to accommodate pump openings and other penetrations. Prefabricated 90° and 135° corner pieces were installed to match the wall geometry and maintain continuity. - Temporary strongbacks

To prevent panel deflection during the subsequent grouting process, timber strongbacks were temporarily fixed in place. - Grouting

Because access from above was limited, traditional tremie grouting could not be used. Instead, grout ports were installed directly through the panels. Cementitious underwater grout was injected into the annular space between the old sheet piles and the new SPiRe®+ wall. This created a solid, bonded repair section. - Finishing

After grouting, the exposed ends of threaded rods were cut flush and capped with protective covers, giving the repair a clean and durable finish.

Results and Benefits

The completed repairs delivered significant improvements:

- Structural restoration: The SPiRe®+ panels with integral ribs provided reinforcement equivalent to conventional steel rebar, restoring load-bearing capacity of the walls.

- Durability: The impervious FRP panels block both oxygen and moisture, the two essential components of corrosion. This ensures that the underlying steel will not deteriorate further.

- Extended service life: The repairs are expected to protect the pump station walls for decades, delaying or eliminating the need for costly full replacement.

- Ease of installation: Lightweight panels allowed crews to perform the work in constrained spaces without heavy equipment.

- Adaptability: Field modifications for pump penetrations and the use of prefabricated corners allowed for seamless integration into existing geometry.

- Cost savings: Compared to replacement with new sheet piles, the SPiRe®+ method offered substantial economic and time advantages.

Broader Implications

This project demonstrates how innovative FRP technology can address the aging infrastructure crisis faced by municipalities across the country. Many stormwater systems built in the mid-to-late 20th century are reaching the end of their service lives, and corrosion of steel elements is a common problem. The SPiRe®+ system provides cities like Weston with a practical, long-term, and environmentally conscious alternative to replacement.