Precision Positioning Systems For Accurate Pile Placement In Marine Projects

Pile installation forms the backbone of marine infrastructure, supporting piers, jetties, breakwaters and offshore platforms. Any horizontal or vertical deviation during installation can compromise long term performance, increase project costs and impose safety risks. Unlike land based installations, marine environments introduce additional challenges such as vessel movement, current, tide variation and complex seabed conditions. Precision positioning systems have become essential in overcoming these challenges. These technologies give contractors the ability to place piles within extremely tight tolerances while maintaining efficient workflows on the water.

Core Components of Precision Positioning Systems

Satellite Based Positioning and Real Time Correction

Modern systems rely on GNSS receivers capable of receiving real time kinematic corrections that enable centimetre level accuracy. With dual antenna heading and stable correction links, operators can maintain precise alignment even when the barge or crane platform is in motion. Real time data allows the operator to compare the design coordinates with the live position of the pile frame, ensuring accurate placement throughout the installation process.

Sensor Fusion and Machine Tool Integration

Advanced guidance tools merge GNSS data with tilt sensors, depth indicators, motion reference units and onboard software. This combination creates an integrated workflow where every change in pile position, inclination or depth is monitored in real time. Operators receive visual feedback that shows the pile’s path and its deviation from the target coordinates. Machine integration also streamlines quality control by logging as built information during each installation.

Adaptation to Challenging Marine Conditions

Marine installation requires equipment that can withstand vessel heave, wave action, wind and current. Positioning systems designed for marine use include motion compensation features that maintain accuracy despite platform movement. These marine specific systems help the installation team maintain confidence in their data even during dynamic environmental conditions.

Benefits of Precision Positioning in Piling Operations

Consistency and accuracy are the most immediate benefits. With real time guidance, the likelihood of incorrect placement is significantly reduced. This directly lowers the cost of rework and minimises delays during follow up construction activities. Operators also benefit from a more controlled workflow since the system reduces the need for manual stakeout or repeated repositioning. Safety improves as fewer personnel need to work close to the pile frame during alignment. Additionally, automatic data logging provides transparency and clear documentation for engineering review and regulatory requirements.

Implementation Challenges and Best Practices

Site Set Up and Reference Network

Achieving high accuracy begins with a reliable correction source. Some projects rely on local base stations while others use network based correction services. Regardless of approach, system stability and signal strength are essential for supporting continuous installation activities. Proper planning of communication links and antenna placement helps maintain the integrity of the positioning solution.

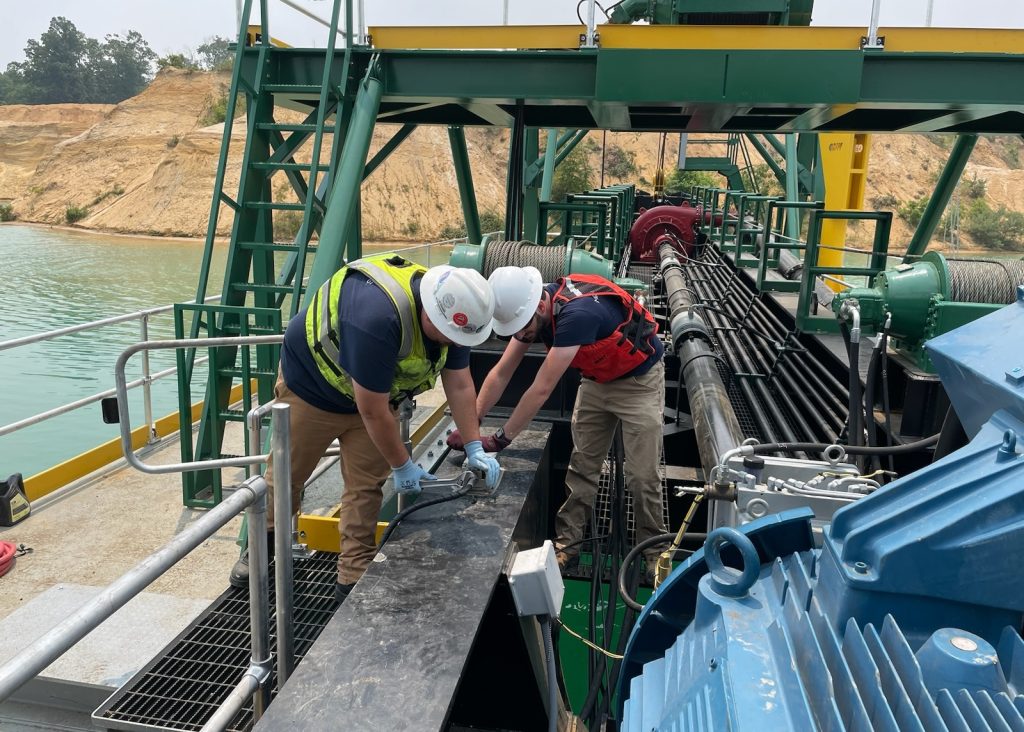

Equipment Integration and Calibration

Before work begins, the system must be calibrated to the exact configuration of the crane, barge or piling frame. This includes alignment checks, tilt and heading calibration and verification of sensor offsets. Once calibrated, the operator can rely on the guidance interface to make informed decisions throughout the installation.

Environmental Factors and Data Confidence

Marine conditions constantly change, affecting platform movement and sensor performance. Systems engineered for coastal and offshore use counteract these challenges with motion sensors, heave compensation and rugged marine grade components. Continuous monitoring builds confidence that the displayed data reflects the true position of the pile relative to the seabed.

Case Example of Real Time Guidance in Marine Pile Placement

A typical marine installation project may involve a floating crane barge installing piles in a navigation channel. By using an integrated positioning system with RTK GNSS, heading sensors and real time motion data, the installation crew can locate each pile position accurately despite current and wave influence. The live display allows the operator to stay on target while driving the pile to the required depth. Once installed, the system logs the location and orientation automatically for engineering verification. This efficient workflow results in faster progress, fewer errors and improved documentation.

Future Trends in Marine Pile Placement Technology

Technology is advancing rapidly across marine construction. The next generation of positioning tools will likely include more powerful sensor fusion, better 3D visualisation and expanded automation capabilities. Cloud connected systems will allow project managers to monitor installation progress in real time from any location. Improved integration between vessel control, motion reference units and installation software will further reduce human error and deliver more predictable outcomes. As marine structures become more complex and design tolerances tighten, the demand for precise guidance tools will continue to grow.

Precision positioning systems have transformed marine pile installation by providing dependable accuracy in environments where traditional methods fall short. By combining GNSS correction, motion compensation, integrated sensors and advanced software, contractors can place piles exactly where they are designed to be. These systems improve efficiency, reduce rework and support high quality construction practices in challenging conditions. Investing in modern marine positioning technology strengthens the reliability and safety of marine infrastructure projects.

They ensure piles are placed within tight tolerances despite vessel movement, currents and tides, reducing rework and long term performance risks.

They combine RTK GNSS with motion sensors and real time correction to compensate for heave, tilt and platform movement during installation. Why are precision positioning systems important for marine pile installation?

How do modern positioning systems maintain accuracy in moving marine environments?