Chapter 6 – Soil Seepage and Drainage

- Pile Buck Guide to Soil Mechanics and Testing

- Chapter 1 – Soil Mechanics Introduction

- Chapter 2 – Identification and Classification of Soil and Rock

- Chapter 2 – Section 1: Soil Formation, Physical Properties, Moisture

- Chapter 2 – Section 2: Soil Surveys, Maps, Investigations, Samples

- Chapter 2 – Section 4: Soil Testing, Equipment

- Chapter 3 – Laboratory Tests and Index Properties of Soils

- Chapter 3 – Section 1: Bituminous Mixtures

- Chapter 4 – Field Exploration, Testing, and Instrumentation

- Chapter 6 – Soil Seepage and Drainage

- Chapter 7 – Analysis of Settlement and Volume Expansion

- Chapter 8 – Slope Stability and Protection

For a complete version of this document click here.

This section covers surface erosion, and analysis of flow quantity and groundwater pressures associated with underseepage. Requirements are given for methods of drainage and pressure relief.

Control of soil erosion must be considered in all new construction projects. Seepage pressures are of primary importance in stability analysis and in foundation design and construction. Frequently, drawdown of groundwater is necessary for construction. In other situations, pressure relief must be incorporated in temporary and permanent structures. For erosion analysis, the surface water flow characteristics, soil type, and slope are needed. For analysis of major seepage problems, determine permeability and piezometric levels by field observations.

6.1. Introduction to Permeability

6.1.1. Theory of Permeability using Darcy’s Law

The flow of water through a soil medium is assumed to follow Darcy’s law:

Equation 6-1: q = k Dh A L

Where

- q = discharge (volume/time)

- A = cross-sectional area

- Dh = height of water drop, length

- L= length of water flow

- Dh/L = the hydraulic gradient (dimensionless; use of this as the hydraulic gradient is based on Bernoulli’s equation)

- k = coefficient of permeability, expressed in length per unit time If we define the hydraulic gradient asEquation 6-2: i = Dh L

The application of Darcy’s law to a specimen of soil in the laboratory is illustrated in Figure 6-1.

The coefficient of permeability, k, is defined as the rate of discharge of water at a temperature of 20o C under conditions of laminar flow through a unit cross-sectional area of a soil medium under a unit hydraulic gradient. The coefficient of permeability has the dimensions of velocity and is usually expressed in centimeters/second. The permeability of a soil depends primarily on the size and shape of the soil grains, the void ratio of the soil, the shape and arrangement of the voids, and the degree of saturation. Permeability computed based on Darcy’s law is limited to the conditions of laminar flow and complete saturation of the voids.

In turbulent flow, the flow is no longer proportional to the first power of the hydraulic gradient. Under conditions of incomplete saturation, the flow is in a transient state and is time-dependent. The laboratory procedures presented herein for determining the coefficient of permeability are based on the Darcy conditions of flow. Unless otherwise required, the coefficient of permeability shall be determined for a condition of complete saturation of the specimen. Departure from the Darcy flow conditions to simulate natural conditions is sometimes necessary; however, the effects of turbulent flow and incomplete saturation on the permeability should be recognized and taken into consideration.

6.1.2. Application of Permeability Data

The permeability coefficient is used to compute the quantity and rate of water flow through soils in drainage and seepage analysis. Laboratory tests are appropriate for undisturbed samples of fine-grained materials and compacted materials in dams, filters, or drainage structures.

- Fine-Grained Soils. Permeability of fine-grained soils (undisturbed or compacted) generally is computed from consolidation test data or by direct measurement on consolidation or triaxial shear specimens. For soils with permeability less than 10-6 cm/sec, a sealant must be used between the specimen and the wall of the permeameter.

- Sand Drain Design. Sand drain design may require complete permeability data for soils to be stabilized, including determination of permeabilities in both vertical and horizontal direction.

- Field Permeability Tests. The secondary structure of in situ soils, stratification, and cracks has a great influence on the permeability. Results of laboratory tests should be interpreted with this in mind, and field permeability tests should be performed where warranted.Permeability is the most variable of all the material properties commonly used in geotechnical analysis. A permeability spread of ten or more orders of magnitude has been reported for a number of different types of tests and materials. Coefficient of permeability is a property highly sensitive to sample disturbance, and shows a wide range of variation due to differences in structural characteristics.143 Permeability of clean, coarse-grained samples is related to D10 size (Figure 6-2).

6.1.3.2. Piping and Subsurface Erosion

Most piping failures are caused by subsurface erosion in or beneath dams. These failures can occur several months or even years after a dam is placed into operation.

In essence, water that comes out of the ground at the toe starts a process of erosion (if the exit gradient is high enough) that culminates in the formation of a tunnel-shaped passage (or “pipe”) beneath the structure. When the passage finally works backward to meet the free water, a mixture of soil and water rushes through the passage, undermining the structure and flooding the channel below the dam. It has been shown that the danger of a piping failure due to subsurface erosion increases with decreasing grain size.

Similar subsurface erosion problems can occur in relieved dry-docks, where water is seeping from a free source to a drainage or filter blanket beneath the floor or behind the walls. If the filter falls or is defective and the hydraulic gradients are critical, serious concentrations of flow can result in large voids and eroded channels.

Potential passageways for the initiation of piping include: uniformly graded gravel deposits, conglomerate, open joints in bedrock, cracks caused by earthquakes or crustal movements, open joints in pipelines, hydraulic fracture, open voids in coarse boulder drains including French drains, abandoned wellpoint holes, gopher holes, cavities formed in levee foundations by rotting roots or buried wood, improper backfilling of pipelines, pipes without antiseepage collars, etc.

Failure by piping requires progressive movement of soil particles to a free exit surface. It can be controlled by adequately designed filters or relief blankets.

6.2. Seepage Analysis

6.2.1. Flow Net

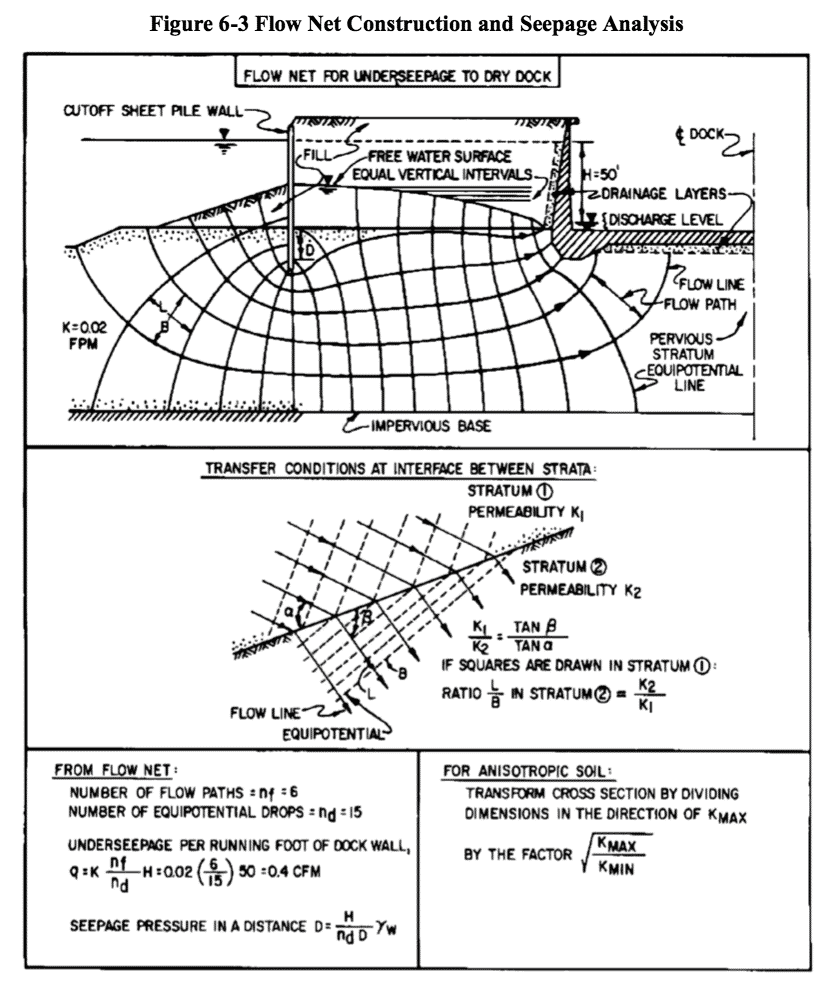

Figure 6-3 shows an example of flow net construction. Use this procedure to estimate seepage quantity and distribution of pore water pressures in two-dimensional flow. Flow nets are applicable for the study of cut-off walls and wellpoints, or shallow drainage installations placed in a rectangular layout whose length in plan is several times its width. Flow nets can also be used to evaluate concentration of flow lines.

6.2.1.1. Rules for flow net construction

- When materials are isotropic with respect to permeability, the pattern of flow lines and equipotentials intersect at right angles. Draw a pattern in which square figures are formed between flow lines and equipotentials.

- Usually it is expedient to start with an integer number of equipotential drops, dividing total head by a whole number, and drawing flow lines to conform to these equipotentials. In the general case, the outer flow path will form rectangular rather then square figures. The shape of these rectangles (ratio b/l) must be constant.

- The upper boundary of a flow net that is at atmospheric pressure is a “free water surface”. Integer equipotentials intersect the free water surface at points spaced at equal vertical intervals.

- A discharge face through which seepage passes is an equipotential line if the discharge is submerged, or a free water surface if the discharge is not submerged. If it is a free water surface, the flow net figures adjoining the discharge face will not be squares.

- In a stratified soil profile where ratio of permeability of layers exceeds 10, the flow in the more permeable layer controls. That is, the flow net may be drawn for more permeable layer assuming the less permeable layer to be impervious. The head on the interface thus obtained is imposed on the less pervious layer for construction of the flow net within it.

- In a stratified soil profile where ratio of permeability of layers is less than 10, flow is deflected at the interface in accordance with the diagram shown above.

- When materials are anisotropic with respect to permeability, the cross section may be transformed by changing scale as shown above and flow net drawn as for isotropic materials. In computing quantity of seepage, the differential head is not altered for the transformation.

- Where only the quantity of seepage is to be determined, an approximate flow net suffices. If pore pressures are to be determined, the flow net must be accurate.

- Groundwater Pressures. For steady state flow, water pressures depend on the ratio of mean permeability of separate strata and the anistropy of layers. A carefully drawn flow net is necessary to determine piezometric levels within the flow field or position of the drawdown curve.

- Seepage Quantity. Total seepage computed from flow net depends primarily on differential head and mean permeability of the most pervious layer. The ratio of permeabilities of separate strata or their anisotropy has less influence. The ratio nf/nd in Figure 6-3 usually ranges from 1/2 to 2/3 and thus for estimating seepage quantity a roughly drawn flow net provides a reasonably accurate estimate of total flow. Uncertainties in the permeability values are much greater limitations on accuracy.

For special cases, the flow regime can be analyzed by the finite element method. Mathematical expressions for the flow are written for each of the elements, considering boundary conditions. A computer solves the resulting system of equations to obtain the flow pattern.

6.3.1. Sheet Piling

A driven line of interlocking steel sheeting may be utilized for a cut-off as a construction expedient or as a part of the completed structure.

• Applicability. The following considerations govern the use of sheet piling: Page 368 of 723

The Pile Buck Guide to Soil Mechanics and Testing © 2007 Pile Buck International, Inc.

o Sheeting is particularly suitable in coarse-grained material with maximum sizes less than about 6 inches or in stratified subsoils with alternating fine grained and pervious layers where horizontal permeability greatly exceeds vertical.

o To be effective, sheeting must be carefully driven with interlocks intact. Boulders or buried obstructions are almost certain to damage sheeting and break interlock connections. Watertightness cannot be assumed if obstructions are present.

o Lossofheadacrossastraightwallofintactsheetingdependsonitswatertightnessrelativeto the permeability of the surrounding soil. In homogeneous fine-grained soil, head loss created by sheeting may be insignificant. In pervious sand and gravel, head loss may be substantial depending on the extent to which the flow path is lengthened by sheeting. In this case, the quantity of water passing through intact interlocks may be as much as 0.1 gpm per foot of wall length for each 10 feet differential in head across sheeting, unless special measures are taken to seal interlocks.

• Penetration Required. This paragraph and the next apply equally to all impervious walls listed in Table 6-1. Seepage beneath sheeting driven for partial cut-off may produce piping in dense sands or heave in loose sands. Heave occurs if the uplift force at the sheeting toe exceeds the submerged weight of the overlying soil column. To prevent piping or heave of an excavation carried below groundwater, sheeting must penetrate a sufficient depth below subgrade or supplementary drainage will be required at subgrade. See Figure 6-4 for sheeting penetration required for various safety factors against heave or piping in isotropic sands. For homogeneous but anisotropic sands, reduce the horizontal cross-section dimensions by the transformation factor of Figure 6-3 to obtain the equivalent cross section for isotropic conditions. See Figure 6-5 for sheeting penetration required in layered subsoils. For clean sand, exit gradients between 0.5 and 0.75 will cause unstable conditions for men and equipment operating on the subgrade. To avoid this, provide sheeting penetration for a safety factor of 1.5 to 2 against piping or heave.

6.3.2. Grouted Cut-off

Complete grouted cut-off is frequently difficult and costly to attain. Success of grouting requires careful evaluation of pervious strata for selection of appropriate grout mix and procedures. These techniques, in combination with other cut-off or drainage methods, are particularly useful as a construction expedient to control local seepage.

6.3.3. Impervious Soil Barriers

Backfilling of cut-off trenches with selected impervious material and placing impervious fills for embankment cores are routine procedures for earth dams.

- Compacted Impervious Fill. Properly constructed, these sections permit negligible seepage compared to the flow through foundations or abutments. Pervious layers or lenses in the compacted cut-off must be avoided by blending of borrow materials and scarifying to bond successive lifts.

- Mixed-in-Place Piles. Overlapping mixed-in-place piles of cement and natural soil forms a cofferdam with some shear resistance around an excavation.

- Slurry-filled Trench. Concurrent excavation of a straight-sided trench and backfilling with slurry of bentonite with natural soil is done. Alternatively, a cement bentonite mix can be used in a narrower trench where coarser gravel occurs. In certain cases, tremie concrete may be placed, working upward from the base of a slurry-filled trench, to form a permanent peripheral wall.

6.4. Design of Drainage Blanket And Filters

6.4.1. Filters

If water flows from silt to gravel, the silt will wash into the interstices of the gravel. This could lead to the following, which must be avoided:

- 1) The loss of silt may continue, causing creation of a cavity.

- 2) The silt may clog the gravel, stopping flow, and causing hydrostatic pressure build-up.

The purpose of filters is to allow water to pass freely across the interface (filter must be coarse enough to avoid head loss) but still be sufficiently fine to prevent the migration of fines. The filter particles must be durable, e.g., certain crushed limestones may dissolve. Filter requirements apply to all permanent subdrainage structures in contact with soil, including wells.

6.5. Wellpoint Systems and Deep Wells

6.5.1. Methods

Excavation below groundwater in soils having permeability greater than 10-3 fpm generally requires dewatering to permit construction in the dry. For materials with a permeability between 10-3 and 10-5 fpm, the amount of seepage may be small but piezometric levels may need to be lowered in order to stabilize slopes or to prevent softening of subgrades. For intermediate depths, wellpoint systems or sumps normally accomplish drawdown.

Deep drainage methods include deep pumping wells, relief wells, and deep-sheeted sumps. These are appropriate when excavation exceeds a depth that can be dewatered efficiently by wellpoint systems alone or when the principal source of seepage is from lower permeable strata.

-

- Construction Controls. For important construction dewatering, install piezometers below the base of excavations and behind slopes or cofferdams to check on the performance and adequacy of drainage system.

- Settlement Effects. Where dewatering lowers the water levels in permeable strata adjacent to compressible soils, settlement may result. See 5.4 for methods of settlement evaluation.

6.5.2. Wellpoint Systems

Wellpoints consist of 1 1/2” or 2” diameter pipes with a perforated bottom section protected by screens. They are jetted or placed in a prepared hole and connected by a header pipe to suction pumps.

- Applicability. Wellpoints depend upon the water flowing by gravity to the well screen. Pumping methods for gravity drainage generally are not effective when the average effective grain size of a soil D10 is less than 0.05 mm. In varved or laminated soils where silty fine sands are separated by clayey silts or clay, gravity drainage may be effective even if the average material has as much as 50% smaller than 0.05 mm. Compressible, fine-grained materials containing an effective grain size less than 0.01 mm can be drained by providing a vacuum seal at the ground surface around the wellpoint, utilizing atmospheric pressure as a consolidating force. See Section 4 for limitations due to iron and carbonate clogging.

- Capacity. Wellpoints ordinarily produce a drawdown between 15 and 18 feet below the centre of the header. For greater drawdown, install well points in successive tiers or stages as excavation proceeds. Discharge capacity is generally 15 to 30 gpm per point. Points are spaced between 3 and 10 feet apart. In finely stratified or varved materials, use minimum spacing of points and increase their effectiveness by placing sand in the annular space surrounding the well point.

- Analysis. Well point spacing usually is so close that the seepage pattern is essentially two- dimensional. Analyse total flow and drawdown by flow net procedure. For fine sands and coarser material, the quantity of water to be removed controls well point layout. For silty soils, the quantity pumped is relatively small and the number and spacing of well points will be influenced by the time available to accomplish the necessary drawdown.

-

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99 -

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00 -

Pile Driving (PDF Download)

$89.00

Pile Driving (PDF Download)

$89.00

-

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

-

Pile Driving (Book)

$89.00

Pile Driving (Book)

$89.00