Chapter 3 – Laboratory Tests and Index Properties of Soils

- Pile Buck Guide to Soil Mechanics and Testing

- Chapter 1 – Soil Mechanics Introduction

- Chapter 2 – Identification and Classification of Soil and Rock

- Chapter 2 – Section 1: Soil Formation, Physical Properties, Moisture

- Chapter 2 – Section 2: Soil Surveys, Maps, Investigations, Samples

- Chapter 2 – Section 4: Soil Testing, Equipment

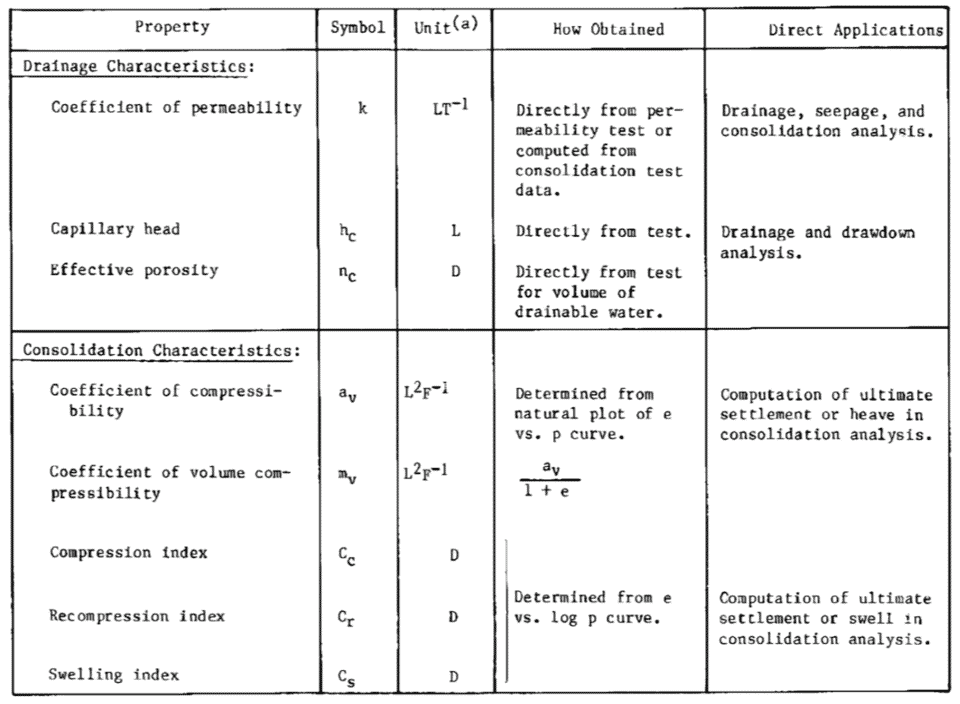

- Chapter 3 – Laboratory Tests and Index Properties of Soils

- Chapter 3 – Section 1: Bituminous Mixtures

- Chapter 4 – Field Exploration, Testing, and Instrumentation

- Chapter 6 – Soil Seepage and Drainage

- Chapter 7 – Analysis of Settlement and Volume Expansion

- Chapter 8 – Slope Stability and Protection

For a complete version of this document click here.

3.1. Overview of Laboratory Testing

Laboratory testing is an important element in foundation engineering. The complexity of testing required for a particular project may range from a simple moisture content determination to specialized strength testing. However, testing can be expensive and time consuming. The foundation engineer should recognize the project problems to be solved to optimize testing, particular strength and consolidation testing.

A sample of soil may be composed of soil grains, water and air. The soil grains are irregularly shaped solids, which are in contact with other adjacent soil grains. The weight and volume of a soil sample depends on the specific gravity of the soil grains (solids), the size of the area between soil grains (voids or pores) and the amount of void space filled with water. Common terms associated with weight-volume relationships are shown in Table 3-1. Of particular note is the void ratio (e) that is a general indicator of the relative strength and compressibility of the soil sample, i.e., low void ratios generally indicate strong, incompressible soils, and high void ratios may indicate weak, compressible soils.

When a load is applied to a soil sample, the deformation that occurs will depend on the grain-to-grain contacts (intergranular forces) and the amount of water in the voids (pore water). If no pore water exists, the sample deformation will be due to sliding between soil grains and deformation of individual soil grains. Experience has shown that rearrangement of soil grains due to sliding accounts for the most deformation. Adequate deformation is required to increase the grain contact areas to take the applied load. As the amount of pore water in the void increases the pressure it exerts on soil grains will increase and reduce the intergranular contact forces. In fact, tiny clay particles may be forced completely apart by water in the pore space.

Deformation of a saturated soil is more complicated than dry soil as water molecules, which fill the voids, must be squeezed out of the sample before readjustment of soil grains can occur. The more permeable a soil is, the faster the deformation under load will occur. However, when the load on a saturated soil sample is quickly increased, the increase is carried entirely by the pore water until drainage begins. Then more and more load is gradually transferred to the soil grains until the excess pore pressure has dissipated and the soil grains readjust to a denser configuration. The process is called consolidation and results in a higher unit weight and a decreased void ratio.

3.2.3. Testing Procedures

Since soils exist in an enormous variety, and since the problems of applied soil mechanics exist in a very great variety, testing procedures for determining the engineering properties of soils (such as strength- deformation relationships) cannot be standardized.

Before any soils testing is requested of a laboratory, the design engineer responsible for formulating the testing program must clearly define the purpose of each test to himself and to the person who will supervise the testing. It is generally necessary to adapt the testing procedures to the specific requirements of an investigation.

For example, the consolidation test can be performed in various ways. What is often called the “standard consolidation test” is performed by always doubling the previous load on the specimen. This procedure will produce time-consolidation curves that usually permit the most precise evaluation of the coefficients of permeability and consolidation. However, these load increments are not always satisfactory for defining the preconsolidation pressure from the shape of the void ratio-pressure curve; for this purpose, a much smaller factor than 2.0 should be used during incremental loading. In addition, the maximum load to which a consolidation test should be continued will depend on the consistency and stress history of the soil and the requirements of the project.

For example, if clay that had been normally consolidated under an effective overburden pressure of 1 ksf is to be loaded by an embankment that will exert an additional pressure of 2 ksf, the consolidation test need not be continued beyond a load of 8 ksf to fulfill the purpose of the test. On the other hand, highly overconsolidated clay that will be loaded by an embankment of substantial height may require that the consolidation test be continued to a loading of 40 ksf or more.

An even greater variety in testing procedures exists for measuring the strength of soils, and the purpose of the tests must be constantly reviewed to insure that the results have meaning with respect to design. Tests that do not measure clearly defined engineering properties such as Atterberg limits, specific gravity, grain-size analyses, and compaction), however, do require adherence to standardized procedures. Even here, the dangers of injudicious testing must be recognized. As an example, compaction test results-must be carefully evaluated if the material coarser than _” (or some other size) has been removed according to the standard method.

Deviations from these procedures may be necessary on occasion, according to the judgment of testing or design engineers, their experience with local soils, or peculiarities of a project. However, to insure that the test methods remain compatible with the purpose of the tests and that the results will be acceptable, every such deviation should be discussed in advance with the design office requesting the tests. In addition, a description of any non-conventional procedure must accompany the test data.

3.2.4. Reliability of Testing Apparatus and Responsibility of Personnel

All who are engaged in soils testing must constantly be aware of the importance of accuracy in measurement. Inaccurate measurements will produce test results that are not only valueless but are misleading.

Each test described below contains a list of the more common possible errors associated with the procedures described in that test. Serious errors can be caused by poorly constructed apparatus (for example, piston friction in triaxial compression chambers or rough finished consolidometer rings), by maladjusted apparatus (liquid limit devices, proving rings, or mechanical compactors), and by worn parts (liquid limit cup or grooving tool or knife edges of lever systems). Regular calibration and inspection must be a standard practice in all laboratories. The personnel performing the tests must be thoroughly familiar with the apparatus, the testing procedures, and good laboratory technique in general.

They must be conscientious in the handling of soils and must appreciate the purpose of each test they perform. Neat, thoughtful work, with the recording of all test data and a continuous watchfulness for irregularities can prevent most errors.

The philosophy should be that one good test is not only far better than many poor tests, but is also less expensive and less likely to permit a misjudgment in design.

3.2.5. Laboratory Facilities

A laboratory preferably should be on a ground floor or basement with a solid floor and should be free of traffic and machinery vibrations.

Separate areas should be designated for dust producing activities such as sieve analyses and sample processing. Temperature control of the entire laboratory is to be preferred. If the temperature-controlled space is limited, this space should be used for triaxial compression, consolidation, and permeability testing.

A humid room large enough to permit the storage of samples and the preparation of test specimens should be available.

3.2.6. Sample Handling and Storage

The identification markings of all samples should be verified immediately upon their receipt at the laboratory, and an inventory of the samples received should be maintained. Samples should be examined and tested as soon as possible after receipt; however, it is often necessary to store samples for several days or even weeks to complete a large testing program.

Every care must be taken to protect undisturbed samples against damage or changes in water content. Such samples should be stored in a humid room and may require rewaxing and relabeling before storage.

Except for special purposes, such as for viewing by designers or contractors or for research, soil samples should not be retained for long periods; even the most careful sealing and storing of undisturbed samples cannot prevent the physical and chemical changes which, in time, would invalidate any subsequent determinations of their engineering properties.

3.2.7. Selection and Preparation of Test Specimens

Under the most favorable circumstances, a laboratory determination of the engineering properties of a small specimen of undisturbed soil gives but an approximate guide to the behavior of an extensive nonhomogeneous geological formation under the complex system of stresses induced by the construction of an embankment or other structure; under the worst circumstances such a determination may have no meaning. In addition, the strength, compressibility, and permeability of a soil in place may vary by several orders of magnitude within a few inches.

No other aspect of laboratory soils testing is as important as the selection of test specimens to best represent those features of a foundation soil that influence the design of a project. The selection cannot be based on boring logs alone, but requires personal inspection of the samples and the closest teamwork of the laboratory personnel and the design engineer.

This cooperation must be continued throughout the testing program since, as quantitative data become available, changes in the initial allocation of samples or the securing of additional samples may be necessary. Second in importance only to the selection of the most representative undisturbed material is the preparation and handling of the test specimens to preserve in every way possible the natural structure and water content of the material.

Indifferent handling of undisturbed soils can result in test data that are erroneous by several times any errors caused by faulty testing apparatus. With but few exceptions, test specimens should always be prepared in a humid room.

Trimming instruments should be sharp and clean and the specimens should be adequately supported at all times; details of the preparation equipment and procedures are presented in the test procedures.

What cannot be gained from any manual, however, is the judgment and awareness necessary to adjust the techniques for each type of material in order to secure the most satisfactory specimens. During the preparation of specimens, the laboratory personnel have the best opportunity to record a complete description of the material and to judge whether the material is truly undisturbed.

The description should include an identification of the material, its color and consistency, the brittleness of the material and the loss of strength upon remolding, and any heterogeneity or unusual characteristics that might prove valuable in analyzing the test results. In addition, any indication of disturbance of boring samples (strata deformed at periphery or distortions concentric with axis of sample) must be noted.

Often these distortions cannot be seen except by slowly drying a slice of the material to water content at which the differences between strata show clearly.45 Photographs of such partially dried slices may be helpful when evaluating the test data and can contribute to improvements in sampling equipment and techniques.

Disturbed samples should never be used for any tests other than classification, specific gravity or water content.

3.2.8. Data Sheets and Report Forms

Examples of suggested form sheets for recording and computing test data are presented in the tests, and some tests show the forms to be used for reporting test results. These can be found in 11.2. The data sheets shown may be satisfactory in many instances, though each laboratory should adopt whatever data sheets are most suitable for their practices and apparatus.

Well-planned data sheets can improve the efficiency of testing and, by encouraging the recording of data which otherwise might be lost, can lead to better testing. Because they are intended for review purposes, these forms often do not display the test results in sufficient detail for interpretation by the design engineer. Therefore, each laboratory should include with the standard report forms whatever tabulated or plotted data are necessary to satisfy the purpose of a testing program.

Graphs should show all the plotted points, not just smooth curves, and be given scales in easily read units, such as 1, 2, or 5 divisions per unit. The report form should contain a complete description of the material, not just the classification, and sketches to illustrate the mode of failure of strength test specimens.

3.5.4. Preparation of Material

3.5.4.1. Selection of Material

It is essential that the same carefully prepared soil mixture be used for determining both the liquid and plastic limit. Layers of soil of different plasticity should not be mixed. Furthermore, if the natural water content is to be determined, the specimen must be taken from an identical mixture to permit valid correlations. If other test results are to be correlated with the liquid and plastic limits, the material used for the determinations must be the same as that tested. Clay shale materials require special preparation as discussed in 3.5.9.

3.5.4.2. Effects of Drying

Whenever possible, soils should be at the natural water content when preparation for testing is begun. If drying has occurred before testing, the limit values may change. The plasticity of soils containing organic colloids and certain types of inorganic colloids derived from volcanic rocks is highly sensitive to drying. The effects of drying can be determined by comparing the liquid limit values of specimens in “undried,” “air dried,” and “oven dried” states.

3.5.4.3. General Preparation of Material

- (1) Samples Passing the 425 mm (No. 40) Sieve. When by visual and manual procedures, it is determined that the sample has little or no material retained on the 425 mm (No. 40) sieve, prepare a specimen of 150 to 200 g by mixing thoroughly with distilled or demineralized water on the glass plate using the spatula. If desired, soak soil in a storage dish with small amount of water to soften the soil before the start of mixing. Adjust the water content of the soil to bring it to a consistency that would require 15 to 25 blows of the liquid limit device to close the groove. The time taken to adequately mix a soil will vary greatly depending on the plasticity and initial water content. Initial mixing times of more than 30 minutes may be needed for stiff, fat clays. If, during mixing, a small percentage of material is encountered that would be retained on a 425 mm (No. 40) sieve, remove these particles by hand, if possible. If it is impractical to remove the coarser material by hand, remove small percentages (less than about 15%) of coarser material by working the specimen through a 425 mm (No. 40) sieve using a piece of rubber sheeting, a rubber stopper, or other convenient device provided the operation does not distort the sieve or degrade material that would be retained if the washing method described in the next paragraph were used. If larger percentages of coarse material are encountered during mixing, or it is considered impractical to remove the coarser material by the methods just described, wash the sample as described in the next paragraph. When the coarse particles found during mixing are concretions, shells, or other fragile particles, do not crush these particles to make them pass a 425 mm (No. 40) sieve, but remove by hand or by washing. Place the mixed soil in the storage dish, cover to prevent loss of moisture, and allow to stand for at least 16 hours (overnight). After the standing period and immediately before starting the test, thoroughly remix the soil.

- (2) Samples Containing Material Retained on a 425 mm (No. 40) Sieve.

- a) Select a sufficient quantity of soil at natural water content to provide 150 to 200 g of material passing the 4250urn (No. 40) sieve. Place in a pan or dish and add sufficient distilled or demineralized water to cover the soil. Allow soaking until all lumps have softened and the fines no longer adhere to the surfaces of the coarse particles.

- b) When the sample contains a large percentage of material retained on the 425 mm (No. 40) sieve, perform the following washing operations in increments, washing no more than 0.5 kg (1 lb) of material at one time.

- Place the 425 mm (No. 40) sieve in the bottom of the clean pan.

- Pour the soil water mixture onto the sieve. If gravel or coarse sand particles are present, rinse as many of these as possible with small quantities of water from a wash bottle and discard. Alternatively, pour the soil water mixture over a 2-mm (No. 10) sieve nested atop the 425 mm (No. 40) sieve, rinse the fine material through and remove, the 2-mm (No. 10) sieve.

- After washing and removing as much of the coarser material as possible, add sufficient water to the pan to bring the level to about 13 mm (1/2”) above the surface of the 425 mm (No. 40) sieve.

- Agitate the slurry by stirring with the fingers while raising and lowering the sieve in the pan and swirling the suspension so that fine material is washed from the coarser particles.

- Disaggregate fine soil lumps that have not slaked by gently rubbing them over the sieve with the fingertips.

- Complete the washing operation by raising the sieve above the water surface and rinsing the material retained with a small amount of clean water.

- Discard material retained on the 425 mm (No. 40) sieve.

c) Reduce the water content of the material passing the 425 mm (No. 40) sieve until it approaches the liquid limit. Reduction of water content may be accomplished by one or a combination of the following methods:

- Exposing the air currents at ordinary room temperature,

- Exposing to warm air currents from a source such as an electric hair dryer,

- Filtering in a Buckner funnel or using filter candles,

- Decanting clear water from surface of suspension, or

- Draining in a colander or plaster of Paris dish lined with high retentivity, high wet- strength filter paper.65

If a plaster of Paris dish is used, take care that the dish never becomes sufficiently saturated that it fails to actively absorb water into its surface. Thoroughly dry dishes between uses. During evaporation and cooling, stir the sample often enough to prevent over drying of the fringes and soil pennacles on the surface of the mixture. For soil samples containing soluble salts, use a method of water reduction such as (i) or (ii) that will not eliminate the soluble salts from the test specimen.

d) Thoroughly mix the material passing the 425 mm (No. 40) sieve on the glass plate using the spatula. Adjust the water content of the mixture, if necessary, by adding small increments of distilled or demineralized water or by allowing the mixture to dry at room temperature while mixing on the glass plate. The soil should be at a water content that will result in closure of the groove in 15 to 25 blows. Return the mixed soil to the mixing dish, cover to prevent loss of moisture, and allow standing for at least 16 hours. After the standing period, and immediately before starting the test, remix the soil thoroughly.

-

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99 -

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00 -

Pile Driving (PDF Download)

$89.00

Pile Driving (PDF Download)

$89.00

-

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

-

Pile Driving (Book)

$89.00

Pile Driving (Book)

$89.00