From the OSHA Files: Pile Driving, Drilling, and Marine Construction Incidents

Real-world incidents reveal how overlooked safety protocols can lead to serious injuries and fatalities on construction projects. Based on documented OSHA investigations, this article focuses on actual cases to highlight common hazards like equipment failures, collapses, falls, and struck-by events. Each case highlights key violations and offers expanded preventive lessons to help contractors integrate better practices into their operations.

This article is based on publicly available OSHA investigation reports, fatality summaries, and enforcement actions. Details are drawn from official records as of the publication date and are intended for educational and awareness purposes only. Readers should consult current OSHA standards, site-specific regulations, and qualified safety professionals for compliance and best practices. Pile Buck and its contributors are not providing legal advice or guaranteeing the completeness of any case summary.

All photographs and images used in this article are stock, illustrative, or unrelated to the specific incidents described. They are included for visual context only and do not depict the actual events, locations, or individuals involved.

Pile Driving Equipment Crushes Operator (2024)

An operator checking pile status was struck and killed by moving equipment. Hazard controls were insufficient.

Lesson: Maintain clear zones around operating machinery and use signaling systems for coordination. Expanding this to include stop-work authority for any unsafe condition empowers teams to halt operations, preventing crushed-by accidents in the fast-paced setting of geotechnical and piling sites.

Geotechnical Engineer Struck During Soil Testing in Bore Pit (2004)

A geotechnical engineer descended into a bore pit to conduct soil tests when he was struck by falling equipment or debris, leading to fatal injuries. OSHA noted failures in securing overhead hazards and inadequate pit protections.

Lesson: Always perform a thorough hazard assessment before entering confined spaces like bore pits, including stabilizing equipment above and using barriers or hard hats with additional overhead protection. This not only prevents struck-by incidents but also allows for quick evacuation if instability is detected, potentially saving lives through proactive engineering controls.

Falling Pile Driver Hammer Strikes Worker (2007)

During steel pile installation with a crane and pile driver, the hammer detached and fatally struck an employee due to inadequate rigging inspections and load securing—violating 29 CFR 1926.753.

Lesson: Implement mandatory pre-use inspections of all rigging components by certified personnel, documenting wear-and-tear to ensure compliance. This practice fosters a culture of accountability, reduces equipment failure risks, and can be paired with training on load dynamics to anticipate issues in high-force operations like pile driving.

Foundation Drilling Caisson Collapse Buries Worker (2011)

Employees were drilling a caisson on a hillside when significant sloughing and belling occurred, leading to a collapse that buried and killed a worker after hours of entrapment. No timely checks for instability were conducted.

Lesson: Conduct continuous monitoring of soil conditions during drilling, using geotechnical data to install shoring or casing as needed. Expanding this to include real-time communication with a competent person on site ensures early detection of belling or sloughing, preventing entombment and allowing for immediate evacuation protocols.

Pile Driving Worker Crushed by Hydraulic Tool (2019)

During pile driving, an employee was caught by hydraulic equipment and sustained fatal head injuries. Guarding and procedures were inadequate.

Lesson: Install machine guards on all moving parts and enforce lockout/tagout during maintenance or adjustments. Expanding training to include hands-on simulations helps workers recognize pinch points early, fostering a safer workflow in the intense environment of pile installation.

Geotechnical Worker Struck by Motor Grader During Soil Testing (2011)

An employee performing compactness tests on an active site was backed over by a motor grader due to lacking traffic controls and high-visibility gear, violating 29 CFR 1926.200.

Lesson: Establish dedicated exclusion zones around testing areas with barriers and require high-visibility clothing for all personnel. Additionally, assign spotters or use backup alarms on vehicles to enhance awareness—turning potential blind-spot accidents into preventable near-misses through layered safety measures.

Barge Worker Falls into Water and Drowns (2019)

A deckhand on a barge during marine construction (bridge work support) fell overboard without a life jacket or fall protection. No rescue boat was immediately available. OSHA cited violations of 29 CFR 1926.106 (working over water) and maritime standards.

Lesson: Require mandatory PFDs (personal flotation devices) for all over-water work, maintain readily available rescue boats/equipment, and conduct regular drills—critical for preventing drownings in marine environments.

Crane Operator Struck by Swinging Load on Floating Platform (2020)

During marine pile-related support work on a barge, a swinging crane load struck and killed an operator due to unstable deck conditions and no tag lines or load control. Violations included inadequate stability and rigging under 29 CFR 1926.1401 and maritime rules.

Lesson: Use tag lines and dedicated signal persons to control swinging loads on unstable platforms. Perform pre-lift stability assessments on barges to avoid struck-by fatalities.

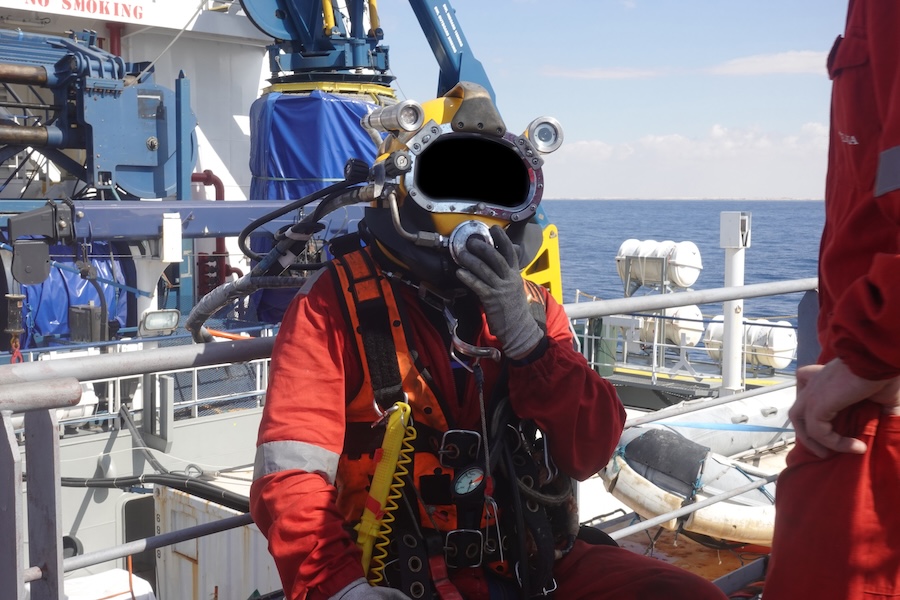

Diver Injured by Underwater Debris During Marine Salvage/Construction (2022)

A commercial diver performing underwater inspections/repairs near a marine structure was struck by shifting debris or equipment, suffering serious injuries. OSHA noted failures in hazard communication, dive team coordination, and protective barriers (violating 29 CFR 1910 Subpart T – Commercial Diving).

Lesson: Establish clear dive plans with surface support, use exclusion zones for overhead hazards, and ensure constant tender communication—essential for safer underwater marine operations.

Pile Driver Operator Falls from Equipment (2013)

An employee standing on the tracks of a pile driver at a construction site fell and sustained fatal injuries. No fall protection was in place.

Lesson: Mandate the use of harnesses, guardrails, or platforms on elevated equipment like pile drivers—with regular training on their proper application. This approach not only complies with fall protection standards but also builds worker confidence, reducing hesitation in dynamic environments where slips are common.

Sheet Pile Falls and Strikes Worker (2015)

During operations, a sheet pile broke free from the hammer and fell—striking and killing an employee in the back, neck, and head. Improper securing was cited.

Lesson: Ensure all piles are securely attached with redundant fastening methods before hammering begins and clear the area of non-essential personnel. By incorporating daily equipment checklists and exclusion zones, teams can mitigate falling object risks—preserving focus on precision work without constant fear of overhead hazards.

Foundation Drill Rig Overturns and Buries Operator (2018)

An operator fell from a foundation drill rig, then was suffocated under collapsing soil. No fall protection or stability assessments were performed, violating 29 CFR 1926.501.

Lesson: Require harness systems and guardrails on rigs, combined with daily soil stability evaluations by a qualified geotechnical expert. This dual focus on personal protection and site conditions prevents overturns and burials, enabling safer repositioning and operation in variable terrains common to deep foundation work.

Trench Collapse in Deep Foundation Preparation (2019)

An employee was working in a nine-foot-deep trench installing pipe when the walls collapsed, burying and killing them. No shoring or sloping was used.

Lesson: Always install trench boxes or properly slope banks for excavations over five feet, with daily inspections for water or vibration issues. Educating crews on soil types and using competent person oversight turns reactive responses into proactive defenses, drastically cutting cave-in risks in foundation prep.

Crane Collapse During Pile Driving Kills Two (2021)

Improper crane assembly caused a collapse during piling on Interstate 10, killing two workers. The employer ignored assembly instructions and regulations.

Lesson: Strictly follow manufacturer assembly guidelines and conduct pre-lift stability checks with certified operators. Incorporating third-party verifications for complex setups like marine or highway piling enhances reliability, preventing catastrophic failures that endanger entire crews.

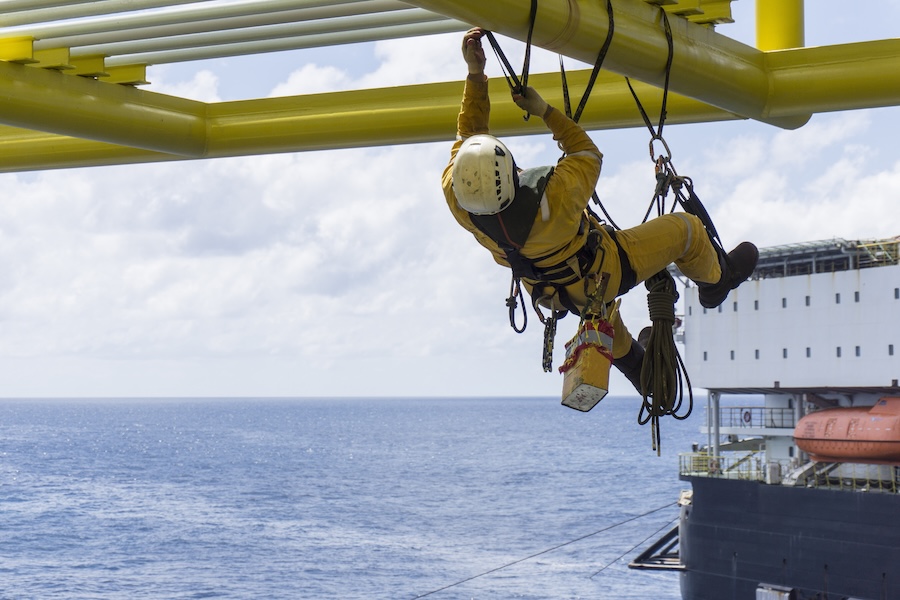

Marine Crane Collapse Leads to Drowning (2023)

A 29-year-old worker was pinned underwater by a fallen crane during marine piling in Key Largo. No stability assessments, guardrails, or life vests were provided—violating maritime standards.

Lesson: Perform barge stability tests before operations and equip all personnel with life vests and rescue gear. Developing comprehensive emergency response plans, including quick-access flotation devices, addresses the unique water hazards in marine construction—turning potential drownings into survivable events.

Repeat Trench Violations Cause Multiple Collapses (2023)

A waterproofing contractor repeatedly exposed workers to collapses in deep excavations without protections, injuring employees multiple times. Willful violations under 29 CFR 1926.651 for no competent inspections.

Lesson: Train and empower supervisors as competent persons to enforce shoring without exceptions, and conduct audits to catch repeat issues. This zero-tolerance policy, reinforced by company-wide safety incentives, breaks the cycle of violations—ensuring long-term compliance in foundation and excavation work.

These OSHA-documented cases demonstrate that many incidents stem from preventable oversights in training, inspections, and protective measures. Applying these expanded lessons—through rigorous site-specific planning and ongoing education—can significantly reduce risks, protect your workforce, and keep projects on track.