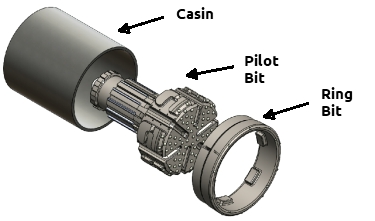

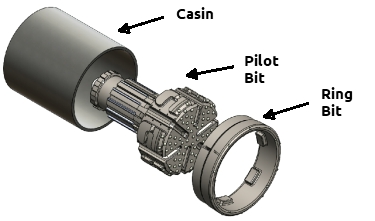

Numa Casing Ring Bit System

Thompson, Connecticut USA – Numa, the world’s leading drilling technology provider, has announced a new range of Casing Ring Bit Systems for simultaneously drilling and casing vertical or horizontal holes in piling, foundation, anchoring, geothermal, and other casing applications. It is a complementary product to Numa’s highly successful Super Jaws® Overburden Bits and Impact Ring Bit Systems®.

Numa’s Casing Ring Bit System consists of a pilot bit, casing shoe, and heavy-duty ring bit and is available in a wide range of sizes for drilling holes 16″ to 48″ (406 – 1219 mm) in diameter. The design is highly configurable, with options for both drill through and non-drill through applications requiring the installation of casing into bedrock. The system also boasts the ability to handle overburden and/or hard rock conditions using either conventional or reverse circulation DTH hammers. Some of the many benefits of Numa’s Casing Ring Bit System include:

- Reduces cost with same pilot bit used with multiple ring sizes

- Provides simple lock design to better engage and disengage from ring

- Eliminates carbide issues locking into pilot

- Cleans holes efficiently through large flushing slots

- Capable for use in vertical and horizontal applications

“We are pleased to announce the addition of Numa’s Casing Ring Bit Systems to our product line,’” said Numa President, Ralph Leonard. “This advancement is yet another example of Numa’s rock-solid reputation for designing dependable drilling products that deliver in mission-critical, harsh applications.”