Micropile Foundations for Transmission Line Structures

View the complete article here.

by Chintan J. Patel

Introduction

At present, the Power and Energy sectors are set to be one of the largest contributions to North America’s economic growth. From 2021 to 2028, the Powerline transmission market is projected to grow at a 4.0% rate and set to exceed 40 billion dollars market value during that span. With the growing electricity demand, rising power load demand, retrofitting of existing infrastructure, efficient grid of electricity lines, mixed-use of micro-grid and renewable energy, the powerline transmission sector requires standard construction practices, strong structures, and robust foundation systems to resist larger loads and stand for its design lifespan.

With an aging infrastructure of transmission lines and the development of high-power voltage lines, foundation systems of overhead structures need to be efficient, resilient, and economical. These days, Energy companies are bidding for modern foundation systems that can be beneficial to their infrastructures and able to transfer large loads from overhead structures. Foundations of transmission line structures should be sufficient to overcome challenges faced due to high terrain conditions, environmentally sensitive areas, compact foot area for construction, difficulties for material transportation, uncertain geological conditions.

Micropiles are becoming groundbreaking solutions for transmission line structures due to their advantages over the past two decades. This innovative and compact foundation system gives more instrumenting benefits for major transmission line structures.

This article discusses the overview of micropile systems, their benefits for transmission line structures, and project photos by Utility companies.

Micropile Overview

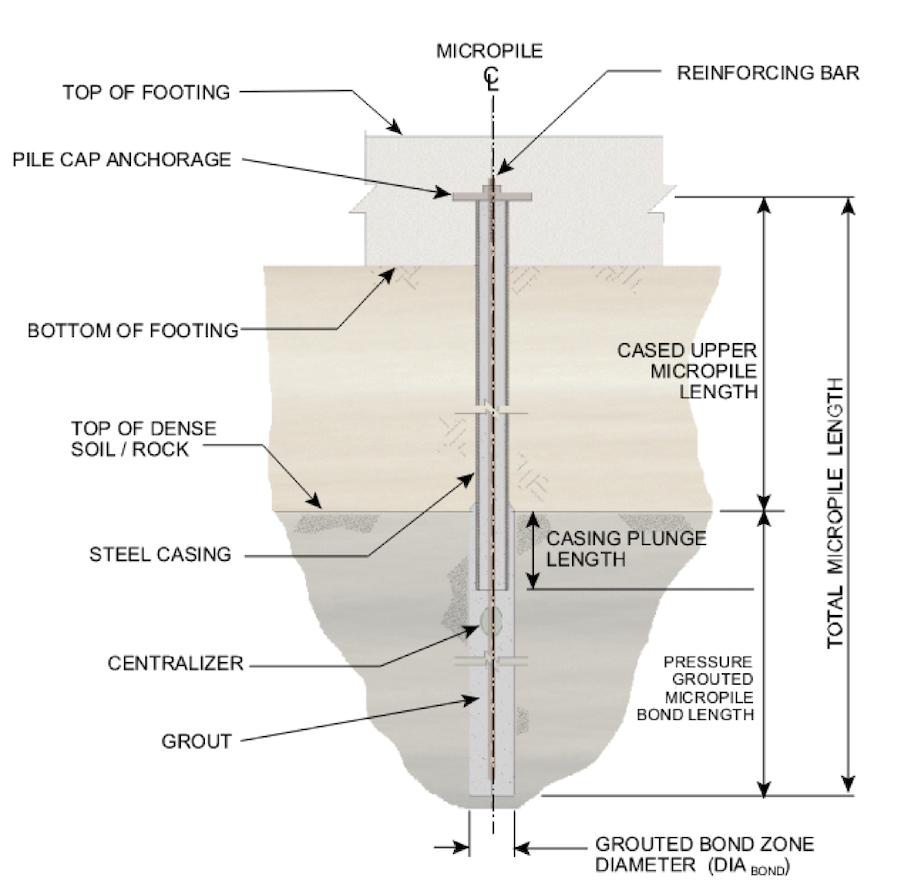

Micropiles are slender, high capacity drilled, smaller diameter (less than 12in) pile systems. Micropile consists of an upper-cased section to resist lateral load followed by uncased grouting bonded section to competent bearing strata and central reinforcing bar to the entire length of the pile. Micropile is constructed through drilling borehole into geological strata to competent bearing layer, lowering reinforced steel bar and grouting at the end.

Micropile upper cased section develops friction to surrounding soil to resist the lateral loads. High strength threaded bar interacts to combined loading in compression and tension from overhead structures. Micropile is connected with a steel pile cap or concrete cap on top with a high-strength coupler and washer and they can also develop high uplift and axial capacity bonded into rock layer.

Accurate determination of lengths can be recorded from the first installation of micropile to site and cased lengths and bond lengths can be adjusted based on accurate characterization. Pile load tests like a proof test, an ultimate/a verification test are used per FHWA recommendations to validate the ultimate capacity of bond area and deflection against test load.

FHWA SA-97-070 and FHWA-NHI-05-039 design standards are the most current publications available for the design of micropiles. AASHTO and IBC have recently published research case studies on micropiles. Deep Foundation Institute (DFI) is developing comprehensive design guidelines of foundations for transmission line structures and also focusing on micropile practices for it. For transmission line structures, a group of micropile systems is constructed for foundation layouts battered away from the center of the foundation to derive capacity from surrounding native soil. Overall stiffness and group combined interactions of micropile systems develop composite resistance against higher combined loads from overhead structures.

Micropiles are advantageous in below favorable options to construct for transmission line structures:

- Significant geological strata challenges

- Transportation, overhead clearance, and access restrictions to a project site

- Environmental sensitive area

- Noise and disturbance limitation

- Relatively uncertain conditions for construction and value engineering indeed

- Hard rock, high groundwater, and special Geotech conditions

- Ability to specify and characterize actual geological conditions while drilling

- Steel pile cap utilization, compact and shop fabrication

Micropiles in transmission line structures are an efficient solution delivered in past for these types of challenging conditions.

View the complete article here.

What are micropiles?

Micropiles are slender, high capacity drilled, smaller diameter (less than 12in) pile systems. Micropile consists of an upper-cased section to resist lateral load followed by uncased grouting bonded section to competent bearing strata and central reinforcing bar to the entire length of the pile. Micropile is constructed through drilling borehole into geological strata to competent bearing layer, lowering reinforced steel bar and grouting at the end.