Crucial Technologies Available to Dredging and Marine Contractors for Positioning, Navigation, and Surveying

View the complete article here.

Whether a contractor is dredging or performing any other type of marine construction project—positioning, navigation, and surveying are essential tasks that must be executed with efficiency and safety.

For this reason, it is imperative that marine contractors have an in-depth understanding of the various technologies available—technologies that have evolved significantly in recent years, and are continuing to evolve each year.

GPS (Global Positioning System)

Widely used in dredging and marine construction projects, GPS is a satellite-based navigation system that provides accurate location information anywhere on Earth.

Consider the dredging of a shipping channel or port. GPS can be used to accurately survey and map the areas to be dredged, including the location of underwater obstacles—such as rocks and other hazards.

GPS can also track the movement of the dredging equipment to ensure that it remains on course and is operating in the correct area—improving productivity and reducing the risk of accidents or damage to the equipment.

And once dredging is complete, GPS can be used to survey the newly-dredged channel or port—ensuring that the finished product meets the required specifications and is ready for vessels to navigate.

However, it should be noted that the accuracy of GPS measurements can be affected by various factors like signal obstruction, atmospheric effects, and receiver noise. For that reason, Differential GPS is used for high-precision work.

DGPS (Differential GPS)

DGPS is a technique that improves the accuracy of GPS measurements by comparing signals received at a fixed reference station with signals received at the location where the measurement is taken. The reference station receives the same GPS signals as the measurement location, but its known location allows it to calculate and broadcast any potential error corrections to the measurement location.

Consider the construction of a bridge over a river. The DGPS system is used to accurately survey and map the riverbed and surrounding areas—as well as track the movement of the barges and cranes being used on the project. The DGPS system can provide real-time location data to the construction team, allowing them to make precise adjustments to the bridge’s foundation to ensure that the bridge is built to the correct specifications.

Could this bridge project been completed with GPS? Probably—but not at the level of precision that DGPS would be able to achieve.

RTK (Real-Time Kinematic)

RTK is a method of determining the precise position of a receiver using measurements from the portion of the signal transmitted by GPS satellites.

It should be noted that RTK can provide much more accurate results than standard GPS by using a fixed-base station, in addition to the mobile receiver.

Consider how RTK can be utilized in marine construction projects for determining the precise location of underwater structures. A survey vessel would be equipped with an RTK-enabled GPS receiver, and a fixed base station would be established on shore. By comparing the portion of the GPS signal received by the survey vessel to the signal received near the base station, the vessel’s position could be determined with great accuracy. This data can then be used to guide the appropriate construction equipment and ensure that underwater structures are placed in the proper location.

Total Station

A total station is a surveying instrument used to measure angles and distances in order to establish control points and to provide accurate data for mapping and construction projects.

Consider the construction of a new marina. In order to survey the site, a total station could be utilized to take measurements of the shoreline and water depths. These measurements could then be used to create detailed maps of the area—showing the location of the shoreline, the water depths, as well as any underwater obstacles that might need to be avoided or removed.

These maps could then be used by the contractor to plan and construct the marina—ensuring that it is built in the correct location and to the correct specifications.

Echo Sounder

Commonly used on vessels to determine water depth and to help navigate through shallow waters, an echo sounder is a device that uses sound waves to measure the depth of water.

Consider how an echo sounder could be utilized for a site investigation for the construction of a new port. The echo sounder would survey the sea floor, and the collected data would be used to create detailed maps of the sea floor—showing the location of any potential underwater obstacles that might need to be removed or avoided during construction. These maps could additionally be used to determine the most suitable location to construct the port.

INS (Inertial Navigation Systems)

INS are a type of navigation technology that uses accelerometers and gyroscopes to measure the linear and angular velocity of a moving object—usually a ship. The system then uses this data to calculate the position, velocity, and orientation of the ship by integrating the velocity data over time.

It should be noted that INS can be used as a standalone navigation system or it can be integrated with other navigation systems—such as GPS—to improve the overall accuracy.

Consider the use of remotely operated vehicles (ROVs) for underwater inspections and construction tasks. The INS can be used to measure the ROV’s position, velocity, and orientation in real-time—even when the ROV is operating in areas with limited visibility or poor communication. This data can be used to ensure that the ROV is operating within a safe area, and to control its movement to avoid any potential hazards. Additionally, the INS can be used to provide precise positioning data for the ROV’s manipulator arms, in order to perform precise tasks such as cutting or welding underwater.

LIDAR (Light Detection and Ranging)

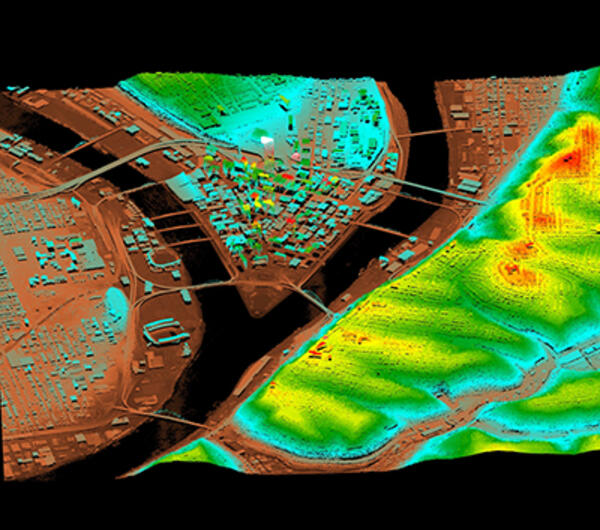

Used to create detailed, high-resolution maps of the seafloor and underwater topography, LIDAR is a remote sensing technology that uses laser beams to measure the distance between the sensor and the surface of the water or seafloor.

Consider how LIDAR could be utilized for a site investigation for the construction of a new port. The LIDAR system could be mounted on a vessel or a helicopter, and the collected data could be used to create detailed maps of the sea floor—showing the location of any potential obstacles that might need to be removed or avoided during construction.

Unmanned Surface Vehicles (USV) and Unmanned Aerial Vehicles (UAV)

USVs and UAVs are autonomous vehicles that can be operated without a human on board and can be utilized for many tasks on a marine construction project—particularly by surveying and mapping, as well as monitoring and inspection.

USVs equipped with sonar and other sensors can be used to survey the sea floor and gather data on the topography and geology of the area.

UAVs equipped with cameras and other sensors can be used to gather aerial images and other data—providing an overall view of the project area to help contractors plan their operations and assess environmental impact.

USVs and UAVs can also be used to monitor the progress of marine construction projects, inspect equipment and various marine structures, and detect and prevent potential safety hazards.

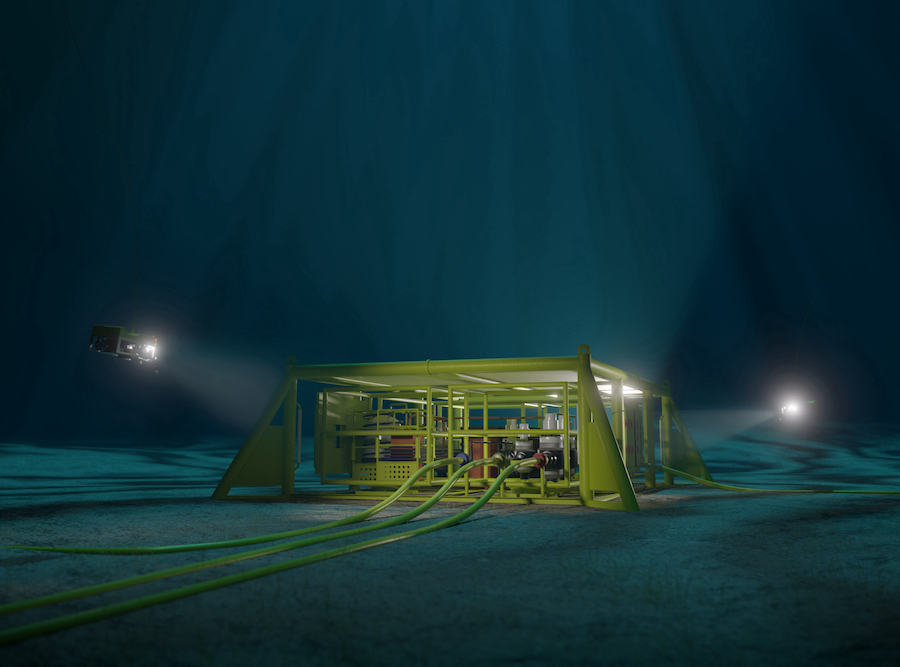

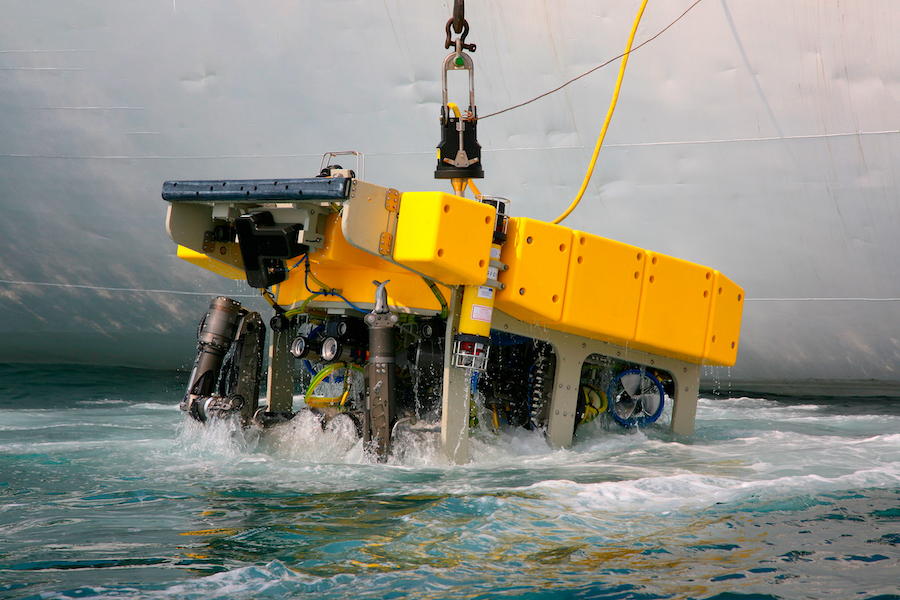

Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs)

Although similar to USVs and UAVs, ROVs and AUVs are different. However, both offer tremendous value to marine construction projects.

ROVs and AUVs are underwater robots that can be controlled remotely or operate autonomously—that is, with the freedom to act independently.

ROVs and AUVs are ideal for underwater inspection and maintenance. ROVs equipped with cameras, lights, and other sensors can be used to inspect underwater structures and equipment. In addition, they can also perform maintenance tasks—such as cleaning and repairing pipelines, seawalls, and mooring systems.

ROVs and AUVs equipped with excavation tools and sensors can also be used to perform subsea excavation and dredging operations—removing sediment and other materials from the ocean floor.

3D Modeling Software

3D modeling software allows marine contractors to create virtual 3D models of objects or environments—such as detailed simulations of the underwater terrain and structures, as well as the placement of equipment and materials during a marine construction project.

Consider how 3D modeling software could be used to create a virtual representation of a dredging site, including the location of underwater obstacles and the depth of the sediment. This data can then be used to optimize the dredging plan and minimize the risk of damage to the equipment and the underwater environment. The contractor can also use the 3D model to simulate the movements of the dredging equipment and vessels, allowing them to identify any potential issues and make necessary adjustments before the start of the project.

Survey Management Software

Survey management software is a type of software that is used to manage and organize survey data and results—such as underwater terrain and structures.

Consider how a marine contractor working on a dredging project could use survey management software to store and analyze data from bathymetric surveys, which provide information on the depth and contours of the seabed. The contractor could then use this data to create maps and models of the underwater environment, as well as to identify areas that require dredging. The software could also be used to track changes in the underwater terrain over time and to monitor the progress of the dredging operation.

Conclusion

Of course, there are other technologies available to dredging and marine contractors—with more technologies developed each year—but the technologies mentioned in this guide should serve as a benchmark.

Again, we should mention that technologies are rapidly improving—by the day—so it is always best to contact manufacturers directly in order to ask specific questions and gather information that will be crucial to your next marine construction project.

View the complete article here.

What are the crucial technologies available for dredging marine contractors?

For dredging marine contractors, crucial technologies include positioning, navigation, and surveying systems. These technologies help improve accuracy, efficiency, and safety in operations. They include GPS, echo sounders, and multi-beam sonar systems for accurate positioning and depth measurements, software for data processing and visualization, and integrated systems for real-time monitoring and control of dredging operations.

Why are positioning, navigation, and surveying technologies important in dredging?

Positioning, navigation, and surveying technologies are important in dredging as they help in accurately determining the location and depth of the dredging area, planning and controlling the dredging operation, and monitoring the progress and results. They help reduce risks and costs, improve operational efficiency, and ensure that the dredging is carried out according to the specifications and environmental regulations.