Leveraging Pre-Existing Foundations: Pros and Cons for Pile Driving Projects

View the complete article here.

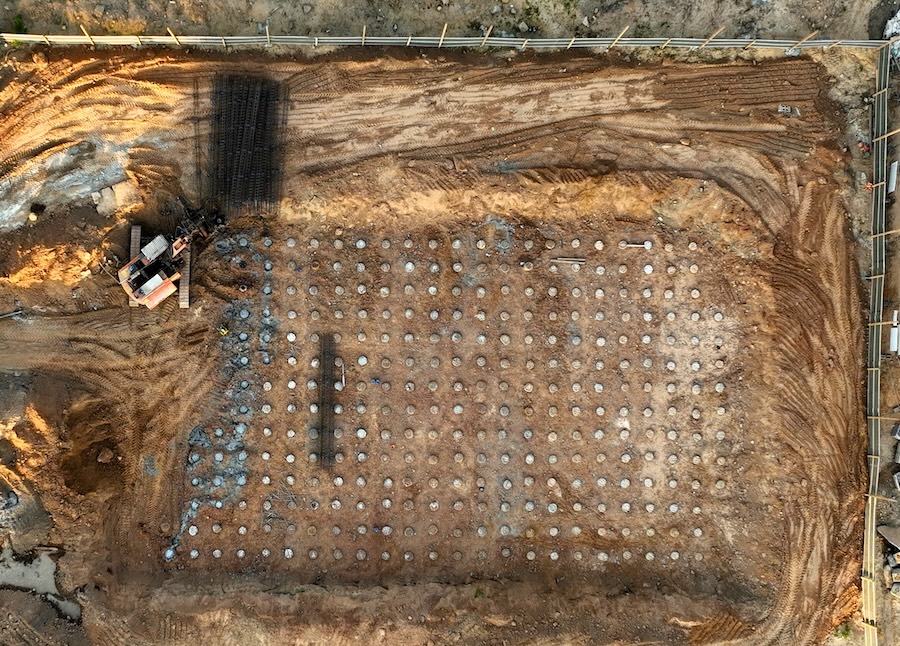

Whether it’s a weathered waterfront pier, an aging bridge support, or a decommissioned dock—reusing existing piles (often made of timber, steel, or concrete) presents an opportunity to support new structures efficiently. But is this approach universally beneficial, or should it be a carefully considered strategic choice? This article discusses the pros and cons, offering marine contractors and engineers a comprehensive guide to determine if building on pre-existing piles aligns with their project goals.

The Case for Reusing Pre-Existing Piles

Reusing pre-existing pile foundations can be a transformative strategy when executed with precision. Here’s a detailed look at the advantages that make this method appealing:

- Cost savings: Bypassing the need to extract pre-existing piles and install new ones can slash project costs by 30-50%, depending on site conditions and material prices. For instance, reinforcing existing steel piles with concrete encasement is often less expensive than driving new piles—especially in areas with high labor rates or difficult access.

- Sustainability: Repurposing pre-existing piles reduces waste and the carbon footprint associated with manufacturing new materials, aligning with the industry’s shift toward eco-friendly practices. This approach can enhance a project’s eligibility for green building certifications, such as LEED, or unlock funding from programs like the U.S. Army Corps of Engineers’ environmental initiatives. For example, reusing piles in a port expansion can minimize sediment disturbance—preserving local ecosystems.

- Time efficiency: In projects with tight deadlines, reusing piles eliminates the time-intensive process of driving new ones—which can take weeks or months in congested urban or marine settings. This is especially valuable for emergency repairs, such as restoring a storm-damaged wharf, where speed is critical. Contractors can redirect saved time to other phases, like superstructure construction, improving overall project flow.

- Proven longevity: Historical examples underscore the durability of well-maintained piles. The timber piles beneath Venice, some dating back to the 9th century, continue to support the city’s iconic structures due to the anaerobic, waterlogged conditions that preserve wood. Similarly, steel piles from mid-20th-century bridges have been successfully reused with proper reinforcement—proving that with the right care, pre-existing foundations can endure for decades more.

The Challenges to Consider

While the benefits are compelling, building on pre-existing piles presents challenges that require careful planning and expertise. Here’s an in-depth exploration of the potential drawbacks:

- Structural uncertainty: Over time, piles can degrade due to corrosion, rot, or fatigue—compromising their load-bearing capacity. Timber piles exposed to air may develop rot, while steel piles in saltwater environments can suffer from rust, and concrete piles may crack under prolonged stress. Without advanced testing methods—such as sonar, core sampling, or dynamic load testing—contractors risk overlooking these issues, which could lead to foundation instability if not addressed. Notably, while pre-existing piles might still be viable—their condition often introduces higher uncertainty, necessitating extra caution to ensure safety.

- Increased maintenance: Even with reinforcement, pre-existing piles may require ongoing monitoring and repairs—adding to long-term costs. For instance, timber piles might need periodic treatments to prevent fungal growth—while steel piles could demand cathodic protection to combat corrosion. These maintenance demands can erode the initial cost savings, particularly in harsh marine environments where wear accelerates.

- Regulatory hurdles: Permitting agencies, including the U.S. Army Corps of Engineers and state environmental bodies, often require extensive documentation to ensure pre-existing piles meet current safety and environmental standards. This process can involve detailed geotechnical reports, environmental impact assessments, and public consultations—potentially stretching timelines by months. Additionally, projects near sensitive habitats may face restrictions on sediment disposal or pile extraction—complicating compliance efforts.

- Incompatibility with new loads: Modern structures often impose greater or different stresses than the original designs accounted for, such as heavier equipment or dynamic loads from traffic. If the pre-existing piles aren’t upgraded, through additional piling or structural enhancements, they may settle unevenly or fail under the new demands. This mismatch requires engineers to perform detailed load analyses, adding complexity to the design phase.

Making the Decision: Is It the Right Fit?

Determining whether to build on pre-existing piles hinges on a thorough evaluation of project-specific factors. For sites with well-documented, intact piles—such as a steel-pile-supported dock decommissioned within the last decade—reinforcement can be a cost-effective and efficient solution.

Conversely, for older or undocumented foundations—such as timber piles from a 1950s wharf exposed to decades of saltwater—the challenges often outweigh the benefits. The lack of historical data and potential for extensive deterioration may necessitate full replacement to ensure safety and longevity.

A hybrid approach, combining pre-existing pile reuse with selective new pile installation, often emerges as the most balanced strategy. This method leverages existing assets while mitigating risks, allowing contractors to adapt to site conditions and regulatory requirements with confidence.

Expert Tips for Success

To maximize the potential of building on pre-existing piles, consider these detailed recommendations:

- Conduct comprehensive site assessments: Employ modern tools like ground-penetrating radar, ultrasonic testing, or pile integrity testing to map pile conditions. Partner with geotechnical experts to interpret data and identify areas needing reinforcement, ensuring a solid foundation for decision-making.

- Engage structural engineers early: Collaborate with engineers to design tailored reinforcement solutions—such as concrete encasement, grouting, or adding new piles—based on the new structure’s load requirements. This upfront investment can prevent costly retrofits later.

- Collaborate with regulatory bodies: Initiate early dialogue with agencies like the U.S. Army Corps of Engineers or local environmental departments to streamline permitting. Provide detailed plans and test results to demonstrate compliance, reducing the risk of delays or rejections.

- Implement real-time monitoring: Install sensors to track pile performance post-construction—monitoring settlement, vibration, or stress changes. This proactive approach allows for timely interventions, extending the foundation’s lifespan and ensuring safety.

View the complete article here.

Can pre-existing piles be reused for new construction?

Yes, if their condition is sound and reinforced, pre-existing piles can support new structures efficiently.

What are the risks of building on old piles?

Risks include structural degradation, increased maintenance, regulatory hurdles, and incompatibility with modern load requirements.