INTERVIEW: W.E. Couplings

Pile Buck’s interview with W. E. Couplings, a UK-based company providing high-quality custom hose and fittings to clients worldwide.

PB: Tell us about W.E. Couplings.

WEC: W.E. Couplings Ltd. was established in 1991. We specialize in the supply of custom hose and fittings. Our company manufactures and stocks a wide range of industrial rubber and PVC hose in long lengths, which can be assembled to your individual requirements. We also have one of the biggest hose crimpers in the world, and we can handle hoses up to a maximum of 24 inches Bore.

PB: What type of piling equipment do you offer?

WEC: We offer Tremie equipment for concrete and piling operations in sizes 6-18 inches with frame and ancillaries. We have Tremie hoppers, suspension jigs, tremie pipes, tremie couplings, and more. Lifting caps, hoppers and pump bends are available with LOLer certs and CE Marking. We also offer safety working platforms. We have recently supplied Rubber Tremie Pipes 14” bore for containing 1 ½” – 2” stone aggregate to a lower level.

PB: What other types of products do you offer?

WEC: Thanks to our In-house design capabilities we have designed, manufactured, and delivered ready-to-install tank drain and suction systems for all sizes and types of storage tank. When the medium in question is highly expensive and highly volatile, our superior quality and reliability is important to prevent contamination of the medium, or even potential ecological disaster in the event of a leak.

PB: Who uses these systems?

WEC: These systems have been utilized all around the world, from airports here in the UK to huge storage farms in the middle east.

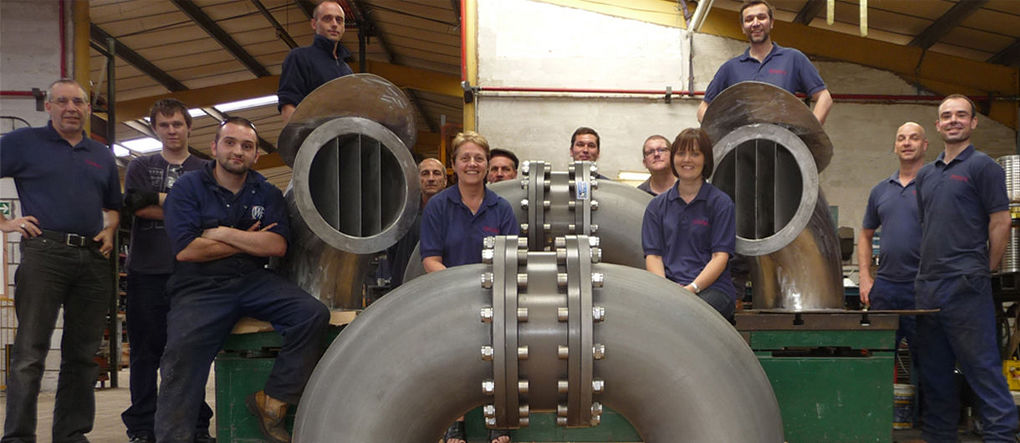

PB: Tell us about your manufacturing capabilities.

WEC: W.E. Couplings Lancashire-based factory has well equipped fabrication, hose fitting, and machining shops. We have nine CNC and two manual horizontal lathes, capable of up to 610mm diameter over the saddle, and up to two meters between centers.

PB: What other manufacturing equipment do you have at this factory?

WEC: We have three vertical CNC machining centers with an up to 1800mm width bed-size allowance. We also have a large-diameter sawing capability of up to 880mm, again set up to handle long lengths.

PB: Which market sectors does W.E. Couplings serve?

WEC: Because we manufacture a large range of fittings from various materials, we can serve many market sectors. Our main market sector up until recently was civil engineering, although now we have completed many contracts for the fuel & oil, agriculture, and food industries. We can supply and test complete assemblies for all types of applications, and for sizes ranging from 1/4″ to 24″ bore.

PB: You also have a large swaging capacity, yes?

WEC: To our knowledge, we believe we have the largest swaging capacity in the world, with internal swaging to 12″ (300mm) bore and external swaging to 24″ (610mm). We currently have eight external swaging machines and four internal machines. We have direct access to various hose manufacturers and carry extensive stocks to facilitate a speedy turnaround service. We have also developed a highly specialized “Layflat” swage, to which we have had exceptional results.

PB: Tell us about the WESwivel Joint.

WEC: The WESwivel joint is one of our flagship products. It’s used in the articulated drain and floating suction systems. It is specially designed and manufactured to allow 360 degrees of low-friction rotation without reducing the through-bore at all.

PB: What configurations do you offer?

WEC: The WESwivel joint is available in a range of configurations, sizes, and materials. It also comes with a customized seal configuration, depending on the medium, pressure, and environment in which it will be used.

PB: What is the coupling system for layflat hose?

WEC: We have developed a heavy duty, field-fittable coupling system for layflat hose. It comprises special tails and clamps that securely grip the layflat material without compromising its surface integrity, like a sharp serrated tail might.

PB: What versions are available?

WEC: We offer this coupling system in 2 bolt (WEFlat21) and 5 bolt (WEFlat1200) versions. This coupling is designed to take the punishment of a layflat application, even in offshore and fuel handling environments. As with some of our other couplings, we can offer this system in hard anodized aluminum material. This provides the user with a superior corrosion resistance, 65% of the weight of their steel counterparts.

PB: What is the Dragline Coupling?

WEC: Dragline is our registered trade name for a low-profile coupling for steel pipes and flexible hoses. This hard-wearing, dynamic coupling has proved essential in a multitude of environments and applications internationally.

PB: Tell us about your industrial drop hoses.

WEC: We have developed the unique and sought-after ability to swage large bore industrial hoses. With both the custom machinery and practical experience of the workers operating it, our UK factory is currently able to handle and externally swage bore sizes up to 24 inches. We plan to expand on this in the future.

WEC: In an offshore environment, after wastewater has been fully treated and certified safe to be put back into the sea, it cannot just be discarded at deck level. A vertical hose string, sometimes reinforced with chain or secured to a leg of the rig, delivers the fluid straight down to the water’s surface to cause the minimum amount of disturbance to any operations that may be going on, i.e., bunkering hose transfer.

PB: We hear W.E. Couplings is doing some interesting work on a remote island.

WEC: We became involved with the ship-to-shore transfer of fuel and other liquids. One project in this field is for a remote island in the Atlantic Ocean. The island, once an outpost of the British Empire, is just beginning to build up its industry and capabilities such as an airport and fueling facilities, and W.E. Couplings are helping to supply the equipment required.

PB: What are hammer lug unions used for?

WEC: The hammer lug union, also known as a “WECO” coupling, hammer lug union, or hammer lug adaptor, is used for quick connecting flexibles and pipelines. It is available in a variety of options, including threaded API line pipe, butt weld, and sour gas service. They are suitable for pressures from 500psi to 20,000psi. The unions are manufactured from forgings and come complete with material certification.

PB: What else do you want our readers to know about W.E. Coupling?

WEC: We are here to serve your specific requirements. Please contact us to get a quote or talk with our sales team.