INTERVIEW: Denso North America

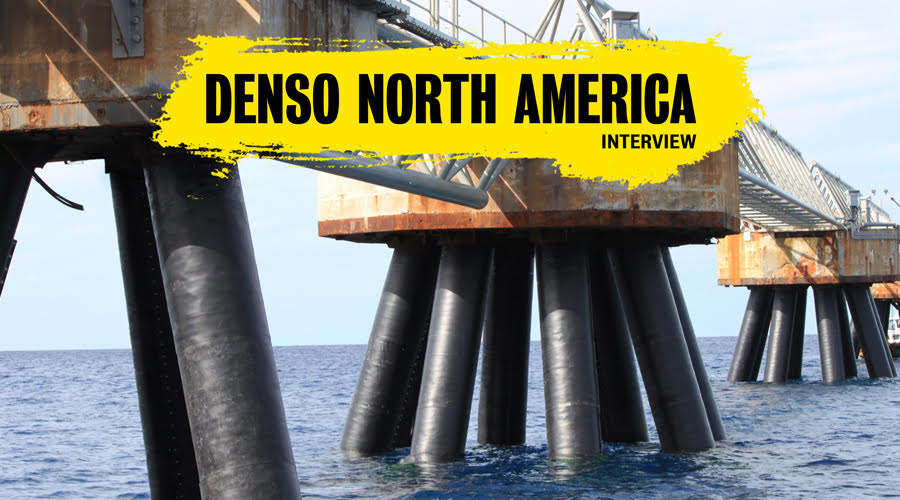

Pile Buck’s interview with Denso North America, a leading manufacturer of anti-corrosion coatings that include Protal liquid epoxies, Denso petrolatum tapes, mastics, primers, bitumen tapes, butyl tapes, hot applied tapes, and a full line of marine pile protection systems.

PB: What is the general purpose of the Denso SeaShield Marine Systems?

D: We offer a wide range of systems to protect marine pilings from corrosion and/or deterioration. They are specifically designed for the protection and rehabilitation of in-situ piles. Most of these repairs can be completed for a fraction of the cost of installing new piles. Most importantly, our SeaShield Marine Systems will provide an additional 30+ years of service life to the existing piles.

PB: What are the most common types of issues that your clients face that require rehabilitation?

D: Quite often pipe pile coatings are damaged during the transportation process from the coating facility to the job site as well as during the driving process. Soon after these piles are driven, corrosion can occur very rapidly, especially in the tidal zone where there are repeated wet/dry cycles. Most liquid coating repairs are not sufficient due to the inability to provide a proper surface preparation. In order to work long term, liquid coatings require an abrasive blasted surface profile. In addition, the surface needs to be clean and dry. This is not the case for the Denso Marine Piling Tape. The surface only needs minimal surface prep. This consists of hand/power tool cleaning to remove any marine growth, loose rust, loose paint and/or foreign matter.

PB: What are the most popular models that Denso offers and the application(s) for each?

D: Our SeaShield Series 2000HD System is the industry standard for protecting new or existing steel pilings from corrosion. The system consists of our Denso Marine Piling Tape (petrolatum wax tape) and an HDPE outercover for long term mechanical and UV protection. The inner layer of tape spirally wrapped around the pile essentially seals out water and air, thus eliminating further corrosion. The product can even be applied underwater by divers. This SeaShield Series 2000HD System has a long established track record with thousands of successful applications in all types of environments dating back to the 1990’s.