Heavy Equipment and Materials – The Hazards of Counterfeiting

By Orest Protch

From this article’s title it might be easy to think that it has found its way into the wrong magazine and that it would be better suited to be featured in one that deals with money or jewelry. If you are sipping coffee in your office as you are reading you may want to seriously consider rummaging in your desk drawers for something stronger.

Every day we gamble. We gamble that whatever vices we may have will not hurt us, or at least not too badly. We gamble on the roads to and from work that the person in the vehicle coming towards us is not texting, inebriated or even falling asleep at the wheel. We gamble that our loved ones and significant others will also make it through the day unscathed. And since you are reading this magazine then every day you are gambling that you are making the right business decisions to keep your books in the black instead of awash with red paint.

But the sharks are always circling and not necessarily just the ones you know about from your bank or credit union. There are others out there and what they can do to your business can be quite devastating if you ignore the signs that they are nibbling or even outright crunching at your livelihood.

Every day in your working career as well as in your family life you are in constant contact with counterfeit products, from clothes and watches to nuts and bolts holding your equipment together to computer chips in your electronic gizmos to the steel products in your backyard barbecue. It is literally impossible not to be in intimate contact with them. Think your car has all the latest safety equipment? What if some of that safety equipment is counterfeit? One of my seminars was for an automotive parts stamping operation’s engineers.

When you look at Illustration #1, it may be hard to believe but the photos all show manufactured products that are at the mercy of counterfeit components. These components are insidious, dangerous and are as common and as widespread as the common cold. How common? One of the reasons why the US space shuttle program was cancelled was that it was almost impossible to ensure the integrity of the shuttles and the safety of its crews. Yes, even NASA is at the mercy of counterfeiters.

The US Senate Armed Services Committee had uncovered 1,800 cases in which the Pentagon had been sold electronics that may have been counterfeit. In total, without even looking too hard, it had found that more than a million fake parts had made their way into aircraft such as the Boeing C-17 transport jet and the Lockheed Martin C-130J Super Hercules. It also found fake components in Boeing’s CH-46 Sea Knight helicopter and the Theatre High-Altitude Area Defence (THAAD) missile defence system. And you think your own equipment and material is safe?

One US Senator said : “A million counterfeit parts is surely a huge number, but I want to repeat that we have only looked at a portion of the defence supply chain. So those 1,800 cases are just the tip of the iceberg.“

Canada’s own military has almost countless crates of unusable counterfeit nuts and bolts and other “simple” everyday use items. Even paper trails through the supply chain can be counterfeit.

According to very conservative estimates the global counterfeit material industry now makes up $1/2 trillion of the yearly global economy of about $85 trillion. But some reports say it is closer to $4 trillion when all counterfeit military spare parts are added and according to the Counterfeiting Intelligence Bureau it is exponentially growing and may be closer to 5-7% of world trade. No one in the worldwide counterfeiting industry seems to want to make official reports available. So guesstimates are based on field inspection work and failures of systems once they are put into service. And lawsuits.

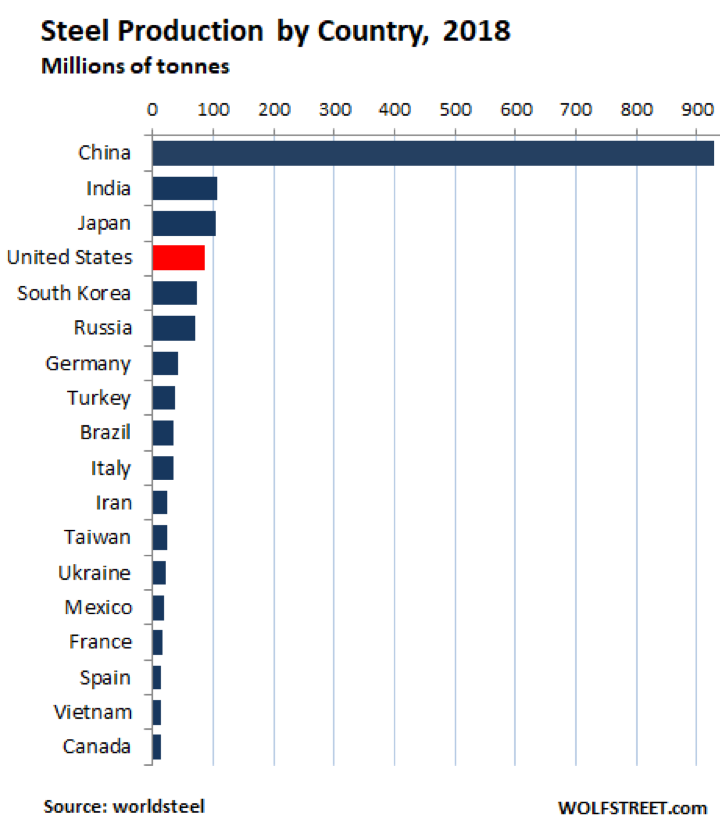

In 70% of the cases the fake parts originated in China, while investigators traced another 20 per cent of cases to the United Kingdom and Canada, known resale points for Chinese counterfeits. Other countries include India, Philippines and South Korea. It depends on the product and fabrication.

Counterfeiters have improved their production methods so that detection can be practically impossible to the naked eye and without high tech testing instrumentation. With this highly developed aptitude to imitate components, counterfeiting is a widespread and increasing trend. Many blame the steady increase of counterfeits to increased access to components via the internet and free trade agreements. In many purchasing instances there are no human to human interactions.

Procurement orders are done with the click of a mouse or keypad. Verification of the associated documentation in terms of codes and standards may be impossible. Today’s e-commerce is booming and is a convenient and less labour demanding purchasing alternative and so the internet is now ground-zero for counterfeit activity. And that is just within the bounds of the normal internet most of us use and not including the 95% of the internet that is made up by the dark web.

The following is a list of the top 10 construction counterfeited materials.

- Steel (including pilings)

- Fasteners

- Valves

- Pipe

- Circuit breakers

- Rotating equipment parts

- Electric equipment

- Pipe fittings

- Pressure vessels

- Cement

As you can see, there is very little that does not impact your own business. In the construction trade using low-grade steel in place of structural steel reduces costs by half and allows the counterfeit manufacturer to undercut the authentic competition. Due diligence becomes essential and critical.

The Construction Industry Institute formed a task force to investigate the scope of counterfeiting in the construction industry. Called Research Team 264 (RT 264), this group from the University of Florida (Gainesville) and Tsinghua University (PRC) conducted a meticulous scientific survey.

Most of the counterfeit items identified in North American construction supply chains come from vendors on the companies’ own approved vendor list. Many otherwise diligent U.S. companies are not regularly updating their supplier lists and they are not testing materials because they think they are dealing with a trusted and reliable source.

The report found that one of the major reasons that makers of counterfeit construction materials continue to produce cheaply made goods is that they simply lack awareness of the importance that standards play in the requirements of their customers. This is particularly true in cases where there is a cultural divide between Asian suppliers and Western manufacturers. And language barriers.

The task force found that one source of counterfeiting is a lack of knowledge and understanding of foreign standards on the part of Chinese manufacturers. Although a project may state US or EU material standards, the Chinese manufacturers will often continue to use their own national standards regardless of whether they meet the customers own standards. The attitude is simply that products that meet Chinese national standards are good enough for everyone else. Chinese manufacturers are used to supplying products according to their own national standards, not their clients’ standards. The belief is that one size should fit all. What you pay for you may not get.

Recently while out for a walk with my wife we saw a new bridge going in. The steel pilings were clearly marked MADE IN CHINA. (Illustration #2) The manufacturer had labeled each piece with a lot of pertinent information including the ASTM Grade, the steel mill Heat Number and other good information. All this is well and good but it means nothing without a verifiable paper trail, the COC, Chain Of Custody, starting with the manufacturer and right through the shipping providers to the various international and local chain of suppliers to the final customer in the field. Labels can be fake.

Identifying counterfeit COC paperwork for any procurements can be easy or it can be very difficult. You have probably seen examples of where documents or instructions written by people whose first language is not English has made you laugh.

But English is a difficult language to master. One simple word like CHARGE has at least 9 meanings. How many can you identify? Spelling and grammar mistakes can be obvious tells, to use the vernacular of popular poker game marathons. But sometimes pure detective and forensic document work is needed.

The following are just some warning flags and indications of counterfeit COC paperwork and products.

- Incorrect or nonexistent manufacturing locations on labels or documentation.

- Incorrect color markings on labels or documentation.

- Part/component coming from source other than the OEM/OCM (Original Equipment Manufacturer (OEM), Original Component Manufacturer (OCM) or authorized sources.

- Hand written labels or stencils on products.

- Misspelled Trade Names or supplier names on labels or documentation.

- Incorrect engraved manufacturer markings on items such as bolts, valves and piping.

- Conflicting ratings and code information on both documentation and on the items.

- Documentation or items listing multiple grade specifications when only one should be noted.

- Documentation accompanying items that have no manufacturer markings.

- Documentation indicating the wrong country of manufacture.

- Documentation or items showing obsolete manufacturer markings.

- Documentation or items showing the wrong trademarks.

- Items with ground-off manufacturers markings.

- Documentation not matching with the items actual measured dimensions.

- Documentation with altered dates, specifications or even signatures.

- Evidence of rework on the items.

- Price obviously too low and not matching historic prices.

- Scare items suddenly becoming available.

Another reason for the increase in counterfeit material and components is the deeply indoctrinated North American politics of recycling. We recycle everything. And even new construction sites need to hire nighttime security to prevent theft of copper wiring that entrepreneurs employed on the wrong side of the law want to recycle to make extra cash.

So what is wrong with recycling? To answer this we need to look at the metallurgical microscopic grain level of metal.

In a past career incarnation I was the melt foreman of a malleable iron foundry with three Brown Boveri Induction melt furnaces. Each melted 13 tons of iron/steel at a time. The iron was recycled from the foundry process itself and the scrap steel came from industrial scrap suppliers.

A crane with a built-in magnet in its grapples tried to shake out any non-metallic metals and alloys before unloading the grapple load into the huge bucket that then dumped the load into the melt furnace. Oil and other organic materials were hopefully burned off by the heat from the molten metal in the furnace but of course was not 100% successful and the inorganic contaminates remained untouched by the +2000°F molten temperatures.

So how does recycling affect the above process? Every time the iron and steel products are scrapped to be remelted the amount of contaminates in the newly made metal increases in concentrations.

In the case of the foundry I was at the recycled iron from process itself would be adding bismuth to the melt every time the melt furnaces were charged. But every time a fork lift came for its ladle of molten metal, two more bismuth pellets were added.

Metal and alloy grades depend on such physical factors as tensile strength, ductility, shear strength and modulus of elasticity and chemical properties such as corrosion inhibiting ability. And these come from the other elements in them. So a specific grade of carbon steel will have specific amounts of iron, nickel, sulphur and other trace metals to give it its physical properties.

But as these other “minor” elements increase over the years due to recycling, then the expected physical and chemical properties will change. Eventually grades and codes will need to be modified. But in the meantime your pilings may be coming from steel mills in countries that do not care about all the above and make no effort to try and control the amount of recycled metal that enters their mills and foundries.

In 2018 a record-breaking 90% of end-of-life shipping tonnage was scrapped on South Asian beaches. 744 large ocean-going commercial vessels were sold to the scrap yards in 2018. Of these vessels, 518 were broken down on tidal mudflats in India and Pakistan. This scrap steel then enters the recycle markets to be sold to steel mills and foundries. The scrap can be a mixture of steel and other alloys.

Other contaminates enter the recycle stream from the demolition of nuclear power plants allowing radioactive scrap material to enter the recycle stream. Radioactive material can also come from the demolition of hospitals and equipment and piping from the oil and gas industries.

Only certifiable and traceable COC’s, Chain Of Custody, will allow you to verify that the grade of steel you are paying for will have the physical and chemical properties that the design engineers and customers want. But you also need to verify the paperwork right from the production mill that may be located in another country to the various international warehouses and customs offices the product passes through and then to your stock pile. At every stage of transport the paperwork may be copied and modified to be added to the COC of steel that does not meet code or grade specifications.

Illustration #5 should be of great concern to you as it impacts the very survival of your business. Start verifying your own paper trail of materials that you use, otherwise you are allowing in the evil specter of lawsuits due to catastrophic failures, premature structural failures, injury and even death.

The author is now retired but continues to put on seminars in basic metallurgy and counterfeit materials. In March 2020 he did a week long metallurgy seminar with emphasis on counterfeit material for a special projects group of the DND, the Canadian Department of National Defense.

How does counterfeiting affect the construction industry, and what are the most commonly counterfeited construction materials?

Counterfeiting in the construction industry is a significant issue, impacting materials such as steel, fasteners, valves, pipe, and more, with the global counterfeit material industry estimated to be as high as $4 trillion.

Why is it essential for businesses to verify the Chain of Custody (COC) for construction materials, and what are the warning signs of counterfeit paperwork and products?

Verifying the COC ensures that construction materials meet code and grade specifications. Warning signs of counterfeit paperwork include incorrect manufacturing locations, color markings, hand-written labels, conflicting information, and discrepancies in ratings or dimensions.