Ground Improvement Design: Methods to Enhance Soil Performance

View the complete article here.

Ground improvement techniques encompass a variety of methods designed to enhance the engineering properties of soil and rock to meet specific project requirements. These techniques are employed to increase soil strength, reduce compressibility, and improve overall stability—making them crucial for the successful execution of construction projects. Common ground improvement methods include aggregate piers, rigid inclusions, stone columns, soil mixing, compaction grouting, permeation grouting, and more—which will all be discussed in this article. Each technique offers unique benefits and applications, allowing engineers to tailor solutions to site-specific conditions and project demands.

In deep foundation construction, the stability and performance of the foundation system are paramount. Ground improvement plays a vital role in ensuring that the soil can adequately support the loads imposed by structures. By enhancing the mechanical properties of the ground—these techniques help mitigate risks associated with settlement, bearing capacity failures, and soil liquefaction. This is particularly important in challenging soil conditions where traditional foundation solutions may be insufficient or overly expensive. Effective ground improvement can also lead to safer, more reliable, and cost-effective foundation systems—ultimately contributing to the longevity and resilience of the constructed facilities.

This guide is going to provide a comprehensive overview of the various ground improvement techniques and their applications, focusing on best practices and practical insights. The goal is to equip deep foundation contractors with the knowledge and tools necessary to select and implement the most appropriate ground improvement methods for their specific project needs.

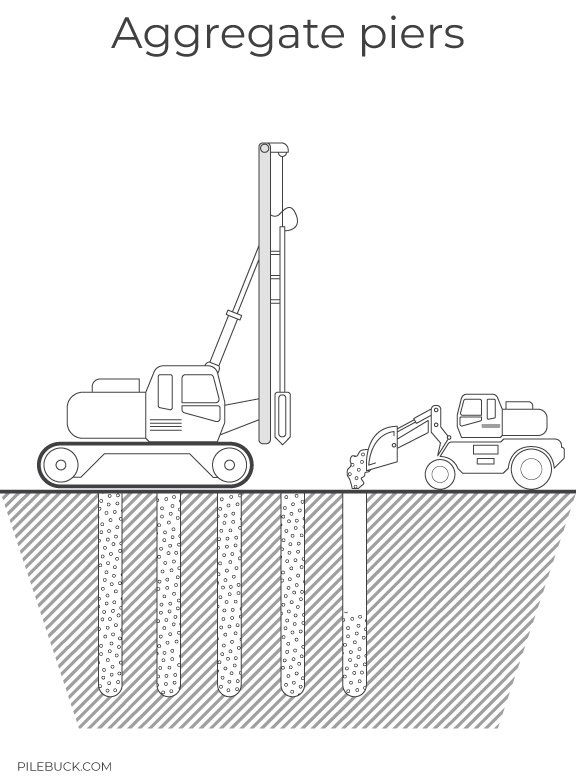

Aggregate Piers

Aggregate piers are ground improvement elements constructed by compacting layers of stone or aggregate in cylindrical holes drilled into the ground. The primary purpose of aggregate piers is to reinforce weak, compressible soils—thereby enhancing their load-bearing capacity and reducing settlement. They are commonly used in projects such as supporting foundations for buildings, bridges, and industrial facilities—as well as stabilizing embankments, retaining walls, and slopes. The benefits include increased load-bearing capacity, reduced settlement, enhanced drainage, cost-effectiveness, and environmental friendliness due to the use of natural and recycled materials.

The design and installation process involves several steps to ensure optimal performance. Materials used typically include clean, crushed stone or recycled materials with appropriate gradation and compaction characteristics. Geotextile fabric may also be used to prevent contamination of the aggregate. Equipment like rotary drilling rigs or augers create holes to the required depth, and compaction equipment such as Vibroflot compacts the aggregate in layers within the drilled holes. For instance, in a commercial building project on soft clay—aggregate piers increased soil load-bearing capacity and reduced settlement, ensuring the structure’s stability. Similarly, they stabilized bridge abutments on loose sandy soils—preventing settlement under heavy loads.

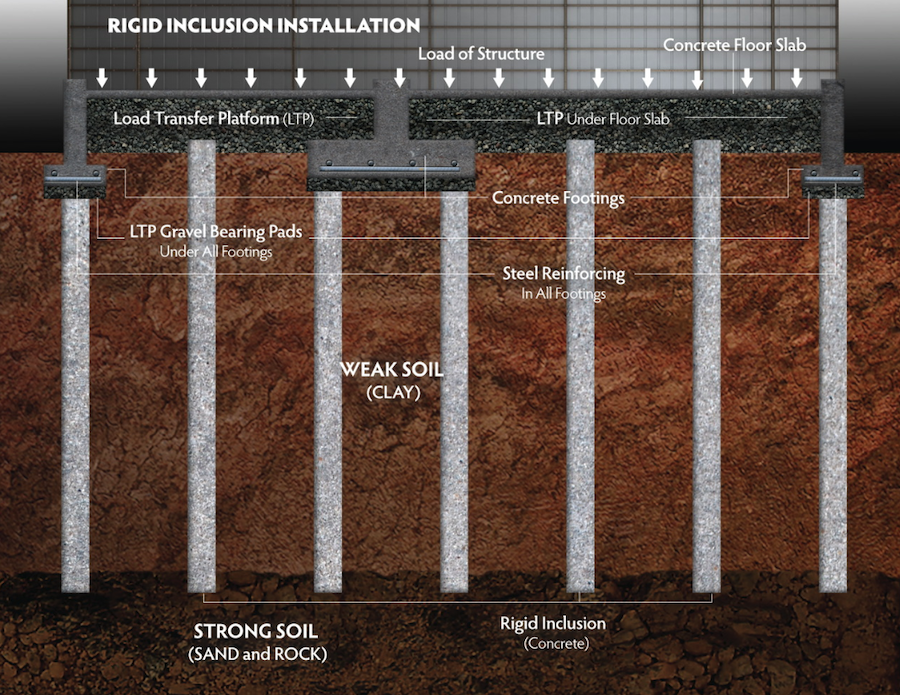

Rigid Inclusions

Rigid inclusions enhance the load-bearing capacity of weak soils by installing stiff elements that transfer structural loads to deeper, more competent layers. These inclusions mitigate settlement and improve overall soil stability, making them essential in challenging soil conditions. They are used in supporting buildings, industrial facilities, and infrastructure like bridges and embankments. The advantages include enhanced load transfer, reduced settlement, and improved bearing capacity.

Design considerations involve understanding load transfer mechanisms and soil-structure interaction. Equipment used includes drilling rigs for creating holes, filled with materials like concrete or grout to form the inclusions. For example, rigid inclusions were used in an industrial facility project to stabilize the foundation on compressible soil—reducing settlement and ensuring long-term stability. In another case, they improved a bridge foundation over soft silty soil—enhancing load-bearing capacity and preventing settlement.

Stone Columns

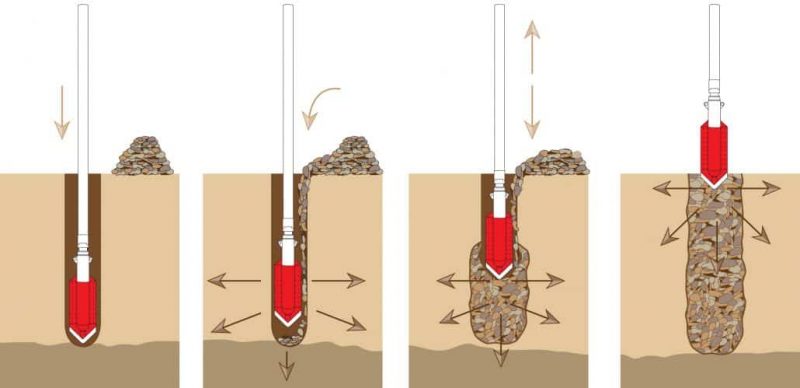

Stone columns involve installing compacted columns of coarse aggregates to enhance soil strength and stability. They are effective in soils prone to settlement and low shear strength—often used in foundations for buildings, bridges, industrial facilities, and stabilizing slopes and embankments. Benefits include increased load-bearing capacity, reduced settlement, enhanced drainage, cost-effectiveness, and environmental friendliness.

The design involves careful consideration of spacing, depth, and material selection. Vibratory probes create holes, and the aggregate is compacted in layers using vibratory techniques. Installation can be dry or wet, depending on soil conditions. An example case study would be a residential project where stone columns reinforced foundations on soft soil, reducing settlement and ensuring stability. Similarly, in highway construction—they stabilized a landslide-prone slope, providing additional support and improving drainage.

Soil Mixing

Soil mixing involves blending the existing soil with cementitious or other materials to improve its properties. It is used to enhance soil strength, reduce compressibility, and improve stability in projects such as foundations, embankments, and slope stabilization. Benefits include increased soil strength, durability, and versatility in application.

The design process includes selecting appropriate mixing agents and additives, considering strength and durability requirements. Installation techniques include in-situ mixing, where soil is mixed in place—and ex-situ mixing, where soil is excavated, mixed, and replaced. Equipment used includes mixing augers and paddles. For example, in a project to stabilize a soft clay embankment—soil mixing improved soil strength and reduced settlement, ensuring long-term stability. In another case, it was used to reinforce the foundation of an industrial facility on weak soil.

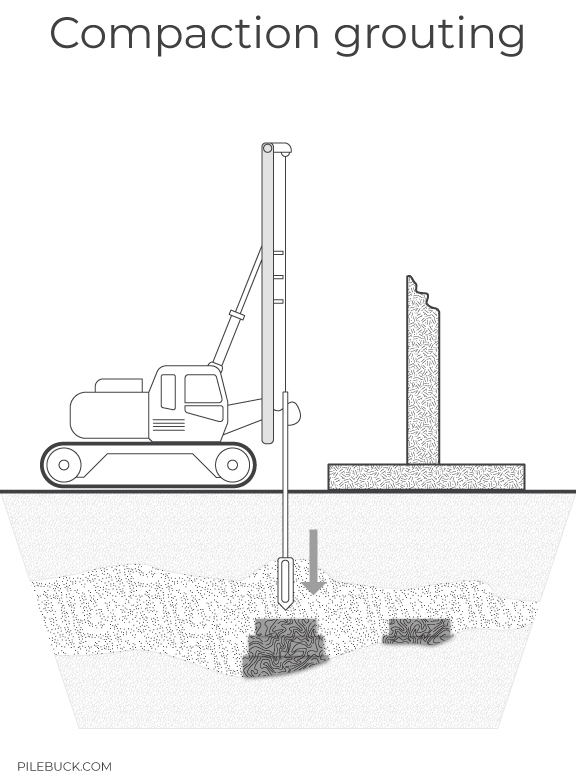

Compaction Grouting

Compaction grouting involves injecting grout into the ground to compact and densify the soil, enhancing its load-bearing capacity and reducing settlement. It is used in a variety of applications—including foundation support, slope stabilization, and void filling. Key benefits include increased soil density, improved load distribution, and reduced settlement.

Design guidelines involve selecting appropriate grout materials and considering pressure and volume requirements. The installation process includes several stages of grouting, using equipment like grout pumps and injection rods. For instance, in a project to stabilize a building foundation on loose sandy soil—compaction grouting increased soil density and reduced settlement, ensuring structural stability. Another example includes stabilizing a slope prone to landslides, where grouting provided additional support and improved soil stability.

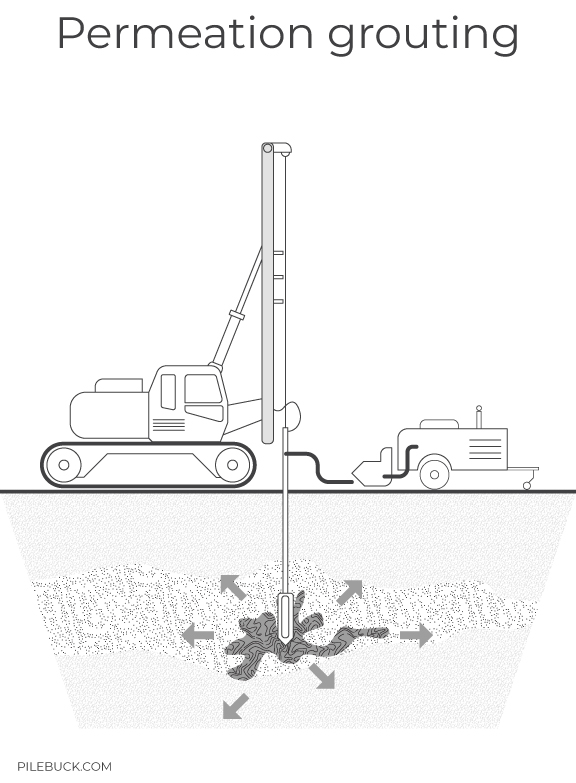

Permeation Grouting

Permeation grouting involves injecting a fluid grout into porous soils to fill voids and bond particles, enhancing soil strength and stability. It is used in applications such as foundation support, groundwater control, and soil stabilization. Benefits include improved soil strength, reduced permeability, and increased stability.

Design parameters include selecting grout materials and considering soil permeability. Installation methods involve grout injection techniques using equipment like pumps and injection pipes. Consider the following case study where, in order to reinforce a bridge foundation on sandy soil, permeation grouting filled voids and improved load-bearing capacity. Another example involves controlling groundwater infiltration in an excavation site, where grouting reduced soil permeability and ensured stability.

Vibro-Compaction

Vibro-compaction is a ground improvement technique that uses vibratory probes to densify granular soils, enhancing their load-bearing capacity and stability. This method is particularly effective for loose, non-cohesive soils such as sands and gravels. It is commonly used for preparing sites for construction projects like buildings, bridges, and industrial facilities—as well as improving the stability of embankments and slopes. The benefits include increased soil density, reduced settlement, improved load distribution, and enhanced stability.

The design and installation process involves assessing soil conditions and determining the depth and spacing of the vibratory probes. Equipment used includes vibratory probes that penetrate the soil and compact it through vibration. The installation process involves inserting the probes into the ground and vibrating them to rearrange soil particles into a denser configuration. For example, in a coastal development project—vibro-compaction was used to densify loose sandy soils, ensuring a stable foundation for the structures. Another example is its use in preparing the foundation for a large industrial facility, where it significantly improved soil density and stability.

Dynamic Compaction

Dynamic compaction is a ground improvement method that involves dropping heavy weights from a significant height to compact the ground, increasing its density and load-bearing capacity. This technique is suitable for a variety of soil types, including granular and cohesive soils. It is used in large-scale construction projects such as airport runways, highways, and industrial sites. The benefits include increased soil density, improved bearing capacity, reduced settlement, and cost-effectiveness for large areas.

The design includes determining the weight of the drop, drop height, and spacing of drop points based on soil conditions and project requirements. Equipment used involves cranes or rigs to lift and drop heavy weights. The installation process consists of repeatedly dropping the weight on the ground in a grid pattern to achieve the desired compaction. For instance, in the construction of an airport runway—dynamic compaction was used to densify the fill material, ensuring a stable and durable surface. In another project, it was applied to an industrial site to improve the load-bearing capacity of the soil before constructing heavy equipment foundations.

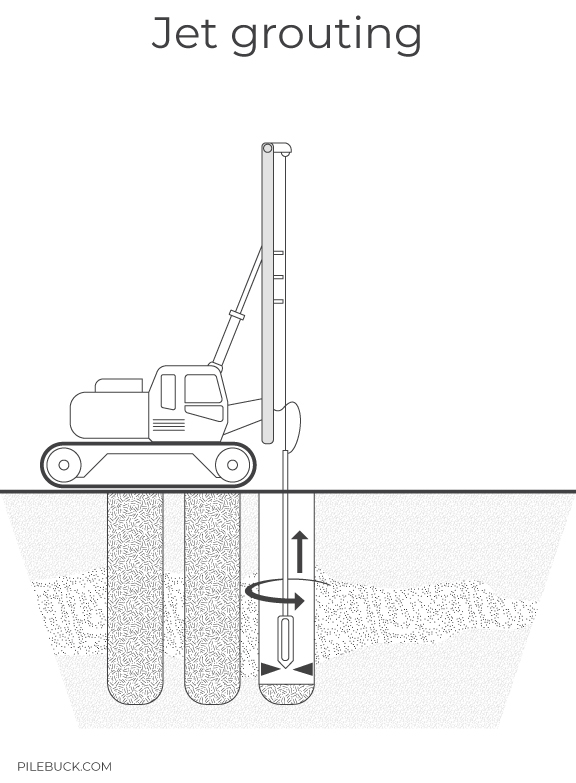

Jet Grouting

Jet grouting is a ground improvement technique that uses high-pressure jets to inject grout into the soil, creating soil-cement columns that enhance strength and stability. This method is effective for a wide range of soil types—including sands, silts, and clays. It is used for foundation support, excavation stabilization, and creating impermeable barriers for groundwater control. The benefits include increased soil strength, reduced permeability, and versatility in application for various soil conditions and project requirements.

The design process involves selecting appropriate grout materials and determining the spacing and depth of the grout columns based on soil conditions and load requirements. Equipment used includes high-pressure grout pumps and rotating jets. The installation process involves drilling a hole to the required depth and then injecting grout at high pressure while rotating and lifting the drill to form a continuous column. For example, jet grouting was used to reinforce the foundation of a building constructed on soft, compressible clay—significantly improving its load-bearing capacity. Another example is its use in creating impermeable barriers for an excavation site, effectively controlling groundwater and ensuring stability.

Conclusion

Ground improvement techniques are essential for enhancing soil properties to meet specific project requirements, ensuring stability, and improving load-bearing capacity. Each technique has unique benefits and applications—making it crucial to select the most suitable method based on soil conditions, project demands, and budget constraints.

Selecting the right ground improvement method is vital for the success of construction projects. Properly chosen techniques can significantly reduce settlement, enhance soil strength, and improve overall project outcomes. It is essential to consider factors such as soil type, load requirements, and environmental impact when making this decision.

Garbin Geostructural Group plays a pivotal role in advancing ground improvement techniques, offering expertise and innovative solutions tailored to meet the complex needs of various projects. Their commitment to quality and technical excellence ensures that contractors receive the most effective and economical solutions for their ground improvement needs.

Contractors are encouraged to consult with experts like Garbin Geostructural Group to determine the optimal ground improvement methods for their specific projects. Expert consultation ensures that the chosen techniques are implemented correctly—resulting in enhanced project performance, safety, and longevity.

View the complete article here.

What is the primary purpose of ground improvement techniques?

Ground improvement techniques enhance soil strength, stability, and load-bearing capacity to meet specific project requirements.

When should dynamic compaction be used for ground improvement?

Dynamic compaction should be used for large-scale projects requiring increased soil density and load-bearing capacity, such as airport runways and industrial sites.