Pile Driving Part V: Subsurface Explorations

View the complete article here

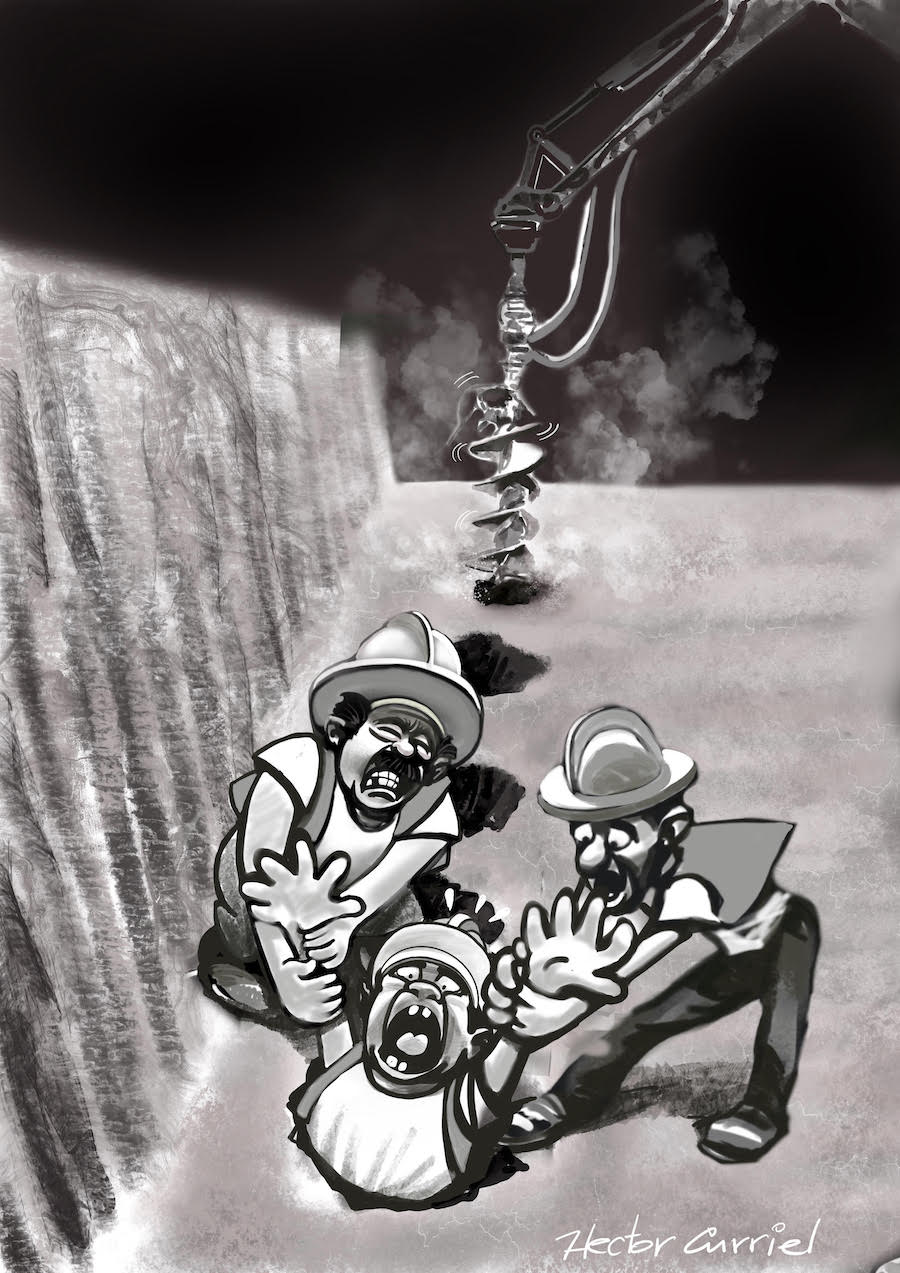

Designing a Safe Foundation

The design of a structure’s foundation requires adequate knowledge of the subsurface conditions at the construction site. If the designer has the appropriate information, then an economical foundation system can be designed. The absence of a thorough foundation study or adequate geotechnical data often leads to a foundation system with a large factor of safety which is generally more expensive and difficult to construct. An unsafe foundation can lead to construction disputes and claims.

A thorough foundation study consists of:

- A subsurface exploration program (which includes borings, sampling, groundwater measurements, and in-situ testing).

- Laboratory testing.

- Geotechnical analysis of all data.

- A determination of design properties.

- Design recommendations.

Subsurface Exploration Phases

There are three major phases in a subsurface exploration program: planning, field reconnaissance, and site exploration.

Planning the Subsurface Exploration Program

The purpose of this phase is to obtain information about the proposed structure and general information on the subsurface conditions. The structural information can be obtained from studying the preliminary structure plan prepared by the bridge design office and by meeting with the structural designer. Approach embankment preliminary design and performance requirements can be obtained from the roadway office. The planning phase prepares the engineer for the field reconnaissance survey and identifies possible problems and areas to scrutinize.

Field Reconnaissance Survey

In this phase you will substantiate the information gained from the subsurface exploration program planning phase and plan the detailed site exploration program. The field reconnaissance for a structure foundation exploration should include:

- Inspection of nearby structures to determine their performance with the particular foundation type used.

- Inspection of existing structure footings and stream banks for evidence of scour (for stream crossings) and movement. Large boulders in a stream are often an indication of obstructions that may be encountered in pile installations.

- Visual examination of terrain for evidence of landslides.

- Recording of the location, type, and depth of existing structures that may be affected by the new structure construction.

- Relating site conditions to proposed boring operations. This includes recording the locations of overhead and below ground utilities, site access, private property restrictions, and other obstructions.

- Recording of any feature or constraint that may impact the constructability of potential foundation systems.

Executing the Site Exploration Program

You will now perform a detailed site exploration program that is based on your planning and field reconnaissance. This will include boring, sampling, and in-situ testing. The purpose of any boring program is not just to drill a hole, but to obtain representative information on the subsurface conditions, to recover disturbed and undisturbed soil samples, and to permit in-situ testing. This information provides the factual basis upon which all subsequent steps in the pile design and construction process are based. Its quality and completeness are of paramount importance. Each step in the process directly or indirectly relies on this data.

Testing Plan

The first step in the site exploration program phase is to prepare a preliminary boring, sampling, and in-situ testing plan.

Pilot Borings

For major structures, pilot borings are usually performed at a few select locations during the preliminary planning stage. These pilot borings establish a preliminary subsurface profile and thus identify key soil strata for testing and analysis in subsequent design stage borings.

Two-Phase Boring Program

During the design stage of major structures, a two phase boring program is recommended. First, control borings are performed at key locations identified in the preliminary subsurface profile to determine what, if any, adjustments are appropriate in the design stage exploration program. Following analysis of the control boring data, verification borings are then performed to fill in the gaps in the design stage exploration program.

Guidelines For Minimum Structure Exploration Programs

The cost of a boring program is comparatively small in relation to the foundation cost. However, in the absence of adequate boring data, the design engineer must rely on extremely conservative designs with high safety factors. At the same time, the designer assumes enormous risk and uncertainty during the project’s construction. The number of borings required, their spacing, and sampling intervals depend on the uniformity of soil strata and loading conditions.

General Guidelines

Erratic subsurface conditions require closely spaced borings. Structures sensitive to settlements or subjected to heavy loads require detailed subsurface knowledge. In these cases borings should be closely spaced. Rigid rules for number, spacing, and depth of borings cannot be established. However, the following are general guidelines useful in preparing a boring plan.

- A minimum of one boring with sampling should be performed at each pier or abutment. The boring pattern should be staggered at opposite ends of adjacent footings. Pier and abutment footings over 30 m in length require borings at the extremities of the substructure units.

- Estimate required boring depths from data gathered in the planning and field reconnaissance phases. The geotechnical engineer should make confirmation of boring depth suitability for design purposes as soon as possible after field crews initiate a boring program.

Resistance Criteria

Although less preferred, it may be possible for field crews to adjust boring depths using a resistance criteria such as: “Structure foundation borings shall be terminated where a minimum SPT resistance of 50 blows per 300 mm has been maintained for 7.5 m.” (This rule is intended for preliminary guidance to drillers. For heavy structures with high capacity piles, the borings must go deeper. A resistance criterion may also be inappropriate in some geologic conditions such as sites with boulder fields.)

Extend Borings Through Unsuitable Strata

All borings should extend through unsuitable strata, such as unconsolidated fill, peat, highly organic materials, soft fine-grained soils, and loose coarse-grained soils to reach hard or dense materials. Where stiff or dense soils are encountered at shallow depths, one or more borings should be extended through this material to a depth where the presence of underlying weaker strata cannot affect stability or settlement of the structure.

Standard Penetration Test (SPT)

SPT samples should be obtained at 1.5 m intervals or at changes in material with the test data recorded in accordance with American Society for Testing and Materials (ASTM) D1586. Undisturbed tube samples should be obtained in accordance with ASTM D1587 at sites where cohesive soils are encountered. The location and frequency of undisturbed soil sampling should be based on project requirements.

Other Investigation Methods

When rock is encountered at shallow depths, additional borings or other investigation methods such as probes, test pits, or geophysical tests may be needed to define the rock profile. When feasible, borings should extend a minimum of 3 m into rock having an average core recovery of 50% or greater with an NX-core barrel (54 mm diameter core).

Field Drilling Log

Drill crews should maintain a field-drilling log of boring operations. The field log should include a summary of drilling procedures including SPT hammer type, sample depth and recovery, strata changes, and visual classification of soil samples. The field log should also include pertinent driller’s observations such as location of ground water table, boulders, loss of drilling fluids, artesian pressures, etc. Disturbed and undisturbed soil samples as well as rock cores should be properly labeled, placed in appropriate storage containers (undisturbed tube samples should be sealed in the field), and properly transported to the soils laboratory.

Water Level Reading

The water level reading in a borehole should be made during drilling, at completion of the borehole, and a minimum of 24 hours after completion of the borehole. Long term readings may require installation of an observation well or piezometer in the borehole. More than one week may be required to obtain representative water level readings in low permeability cohesive soils or in bore holes stabilized with some drilling muds.

Backfill and Seal Boreholes

All boreholes should be properly backfilled and sealed following completion of the subsurface exploration program, data collection, and analysis. Borehole sealing is particularly important where groundwater migration may adversely affect the existing groundwater conditions (aquifer contamination) or planned construction (integrity of tremie seals in future cofferdams).

Descriptions of More Common Subsurface Tests for Pile Foundations

The capacity of the soil medium surrounding the pile can be estimated from geotechnical engineering analysis using the following subsurface tests:

- Shear strength parameters of the soil surrounding the pile.

- Pressure meter or dilatometer test data.

- Dynamic penetration test data (i.e., Standard Penetration Test).

- Static penetration test data (i.e., static cone penetrometer).

Common Errors in SPT Tests

Common Errors in SPT Tests

SPT tests are subject to common errors, some of which are:

- Effect of overburden pressure. Soils of the same density will give smaller SPT N values near the ground surface.

- Variations in the 760 mm free fall of the drive weight, since this is often done by eye on older equipment using a rope wrapped around a power takeoff (cathead) from the drill motor. Newer automatic hammer equipment does this automatically.

- Interference with the free fall of the drive weight by the guides or the hoist rope. New equipment eliminates rope interference.

- Failure to properly seat the sampler on undisturbed material in the bottom of the boring.

- Inadequate cleaning of loosened material from the bottom of the boring.

- SPT results may not be dependable in gravel. Since the split spoon inside diameter is 35 mm, gravel sizes larger than 35 mm will not enter the spoon. Therefore, soil descriptions may not reflect actual gravel content of the deposit. Also, gravel pieces may jam the end of the spoon that may get plugged and cause the SPT blow count to be erroneously high.

- Samples retrieved from dilatant soils (fine sands, sandy silts) which exhibit unusually high blow count should be examined in the field to determine if the sampler drive shoe is plugged. Poor sample recovery is an indication of plugging.

With all of these variations, for use in design, SPT values should be corrected for at least two factors: the overburden pressure and the efficiency of the hammer.

Conclusion

A well planned and executed foundation study should result in subsurface exploration data that clearly identify subsurface stratigraphy and any unusual conditions, allow laboratory assessments of soil strength and compressibility, and document the groundwater table conditions. This information permits a technical evaluation of foundation options and probable costs.

View the complete article here

What is Field Drilling Log?

A drilling log is a written record of the geological formations (soil layers), according to depth. The field log should include a summary of drilling procedures including SPT hammer type, sample depth and recovery, strata changes, and visual classification of soil samples.

When do you measure the water level in your borehole?

The water level reading in a borehole should be made during drilling, at completion of the borehole, and a minimum of 24 hours after completion of the borehole. Long term readings may require installation of an observation well or piezometer in the borehole.

Common Errors in SPT Tests

Common Errors in SPT Tests