Key Steps To Profitable Foundation Drilling

Click here to view the complete article.

Unlike geothermal and water well drilling operators, a foundation drilling contractor is a small cog in a large wheel. Whether it is civil construction or bridge construction, foundation drillers work with the prime contractors and perform within the confines of the design parameters of the larger project.

The activities the foundation drillers perform, such as anchored earth retention, pile construction and drilled shaft foundations, are all determined by the factors that govern the engineering project they are part of. This necessitates a closer partnership between foundation drillers and prime contractors.

A lot of issues determine the profitability of foundation drilling operations and the contractors must remain vigilant of poor bidding practices, delays, change-orders, budget overruns, distrust, disputes, and technical challenges to make sure that the drilling job is completed safely, soundly and profitably. This white paper discusses some of the key steps foundation drilling contractors need to take to keep their jobs profitable.

1. THOROUGHLY STUDY THE SITE CONSTRUCTION REPORT

When a foundation drilling contractor is called in by a prime contractor, in most cases, some kind of preliminary work is already done on the project. The prime contractor will have access to site investigation reports performed on the project site before he or she bid for the project.

These site investigation reports are a good source of information which every drilling contractor should study before bidding any work. The site investigation reports usually have a series of test borings or core borings done on site to check the soil properties and other geological information.

A careful analysis of these reports will provide the drilling contractor with a lot of information critical to understanding the scope of the work such as; the type, size, quantity and the structural details of the piles that need to be constructed; site specific information about the structural nature of the overburden and rock layers (e.g. clays, glacial till, shale rock etc.) will be detailed in the bore logs on these reports.

There are different types of deep foundation piles such as end bearing piles, skin friction piles, settlement reducing piles, tension piles, laterally loaded piles, etc., but end bearing and friction piles are the two most commonly used construction techniques.

End bearing piles are deep foundations which terminate in hard, relatively impenetrable material such as rock or very dense sand, gravel and sometimes limestone. They derive most of their load bearing capacity from the resistance of the stratum at the base of the pile. This requires foundation drillers to drill down through all the soft soil layers and drill into the bed rock and construct the pile.

Drillers need to case the pile all the way down to the bed rock and drill further into the bed rock. Once the hole is drilled and cased common practice is to pressure fill the cavity with concrete. The pre-constructed steel pile is then lowered into the hole. Upon curing of the concrete the casing is removed leaving a constructed pile. This construction technique displaces the load on the pile into the solid bed rock.

Friction piles obtain a greater part of their carrying capacity by skin friction or adhesion. This tends to occur when piles do not reach an impenetrable stratum but are driven for some distance into a penetrable soil. Their carrying capacity is derived partly from end bearing and partly from skin friction between the embedded surface of the soil and the surrounding soil.

Foundation drillers employ pile driving machines to drive the casing down into the ground, beating it until it doesn’t go any further. They drill down through the casing; drill underneath the casing and then pressure fill the hole with concrete. The casing is sometimes lifted as the hole is pressure-filled or removed after the concrete has cured.

The concrete being forced into the hole under pressure swells out underneath the casing. As the casing is removed the bond between the concrete and the soil layers creates a friction on which the load of the pile is handled.

Your site investigation report will help you choose the correct type of the pile method that should be employed. It also helps you to arrive at better informed decisions regarding pile bearing capacity and the methods of verification being used on site; specification of structural materials.

2. UNDERSTAND YOUR CAPABILITIES

Every foundation drilling contractor needs to have a thorough and realistic understanding of their firm’s capabilities in handling the size and scope of the drilling operations. The foundation drilling industry is littered with examples of when a contractor has embarked on a project exceeding his or her capabilities and has to call in external assistance half-way through the job; incurring expenses and compromising the profitability of the contract.

You need to understand the capabilities in terms of your expertise and experience and then the capabilities of the equipment you employ in foundation jobs. Both are very important to be able to sail through drilling assignments smoothly. A mismatch between your capabilities and the requirements of the project may set you on a very huge and expensive learning curve.

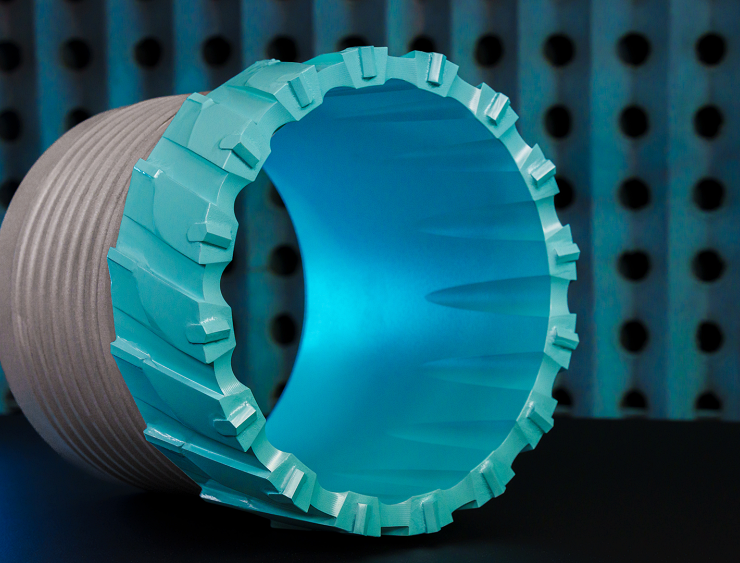

Capabilities of equipment are something foundation drillers should focus on. If their inventory consists of smaller rigs then their machinery is best suited for micro pile work in 5-. Inch OD, 6-5.8 inch OD, 7 inch OD, and 7-7.8 inch OD slots. These are the standard casing sizes used in foundation drilling industry. Since most projects build piles according to the standard casing sizes available in the industry, the smaller rigs have the capability to handle such micro pile and tie back work.

Such rigs are also capable of building slanted piles in some bridge construction work. If a wall needs to be built at an angle of 70 or 80 degrees, a number of holes can be drilled from the side and anchors can be pushed into the bed rock so that walls can be attached firmly to these anchors dug deep into the solid rock.

When foundation drillers try to employ the same machinery in drilling holes of large diameter, such as 20 inch or 24 inch, there is a serious mismatch between the available and the required capabilities. Smaller rigs just donft have the required torque needed and in most cases will not have the pullback capability to extract tooling safely.

One way to solve this problem is to seek outside resources from specialists who have the experience in handling such large diameter works. By outsourcing or subcontracting different parts of your job to different specialists you can avoid an expensive learning curve and you can actually capitalize on their expertise and keep your foundation drilling job profitable.

Click here to view the complete article.

Why do you need to thoroughly study site construction reports?

The site investigation reports usually have a series of test borings or core borings done on site to check the soil properties and other geological information. A careful analysis will provide the drilling contractor with a lot of information critical to understanding the scope of the work such as; the type, size, quantity and the structural details of the piles that need to be constructed.

What are the most critical steps to profitable foundation drilling?

1. Thoroughly study site construction reports. 2. Understand your capabilities in terms of your expertise and experience and then the capabilities of the equipment you employ in foundation jobs.