Floating Concrete Breakwater Overcomes Worst Storms

When it comes to heavy vessels and heavier weather, the protection afforded by the SFBW1000 floating concrete breakwater pontoon is unrivaled in the marketplace. An innovative SF Marina design proven through 40 years of storms, cyclones, hurricanes and typhoons, the wave attenuator safeguards countless commercial and megayacht ports worldwide.

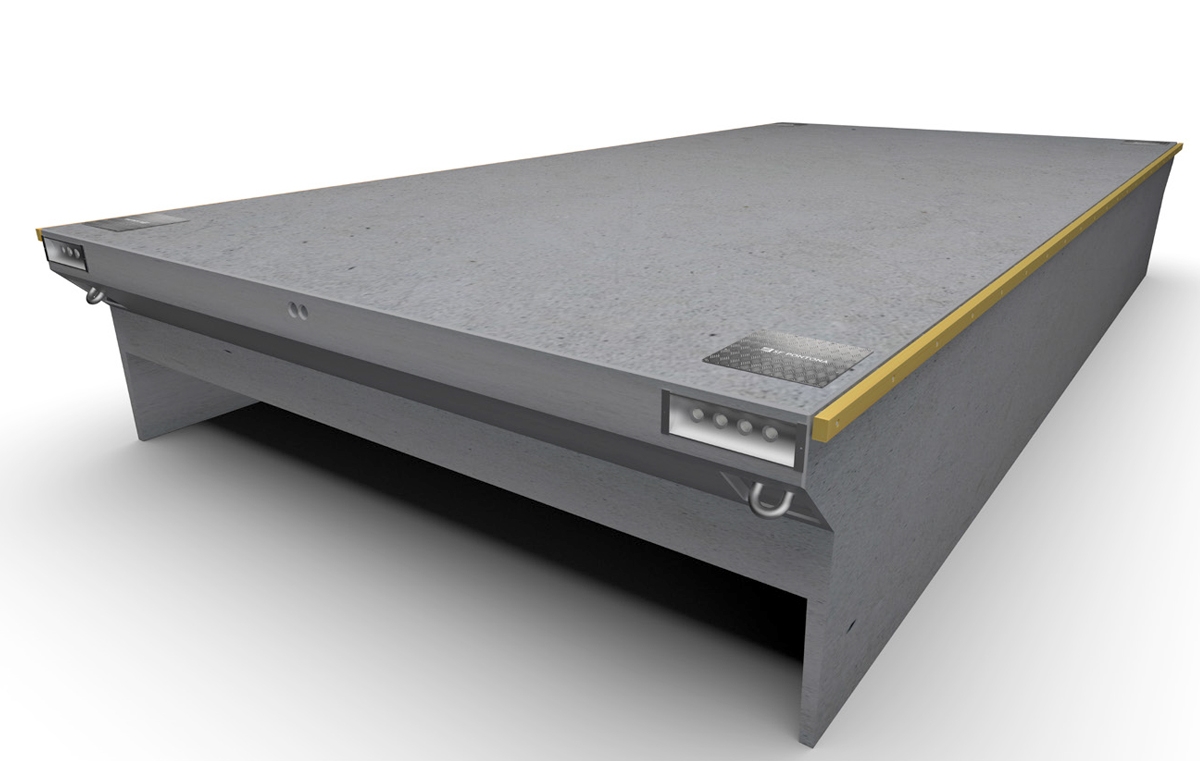

The key to the success of the SFBW1000 lies in its engineered geometry, innovative coupling system, and advanced mooring solution. Specific formulations of concrete refined for marine applications, along with carefully engineered reinforcement, makes each 65′ L x 32′ W pontoon’s approximate mass of 220 US tons stable for vehicles to drive on. Encapsulated flotation affords each SF Marina breakwater a high degree of buoyancy, making it virtually unsinkable. Conduits can be molded into the concrete for fuel, water, electrical, waste, and other utilities.

When wave energy exceeds the SFBW1000 breakwater’s maximum absorption load, couplers comprised of stainless steel components and heavy rubber cylinders allow excess energy to pass through. Highly versatile, SF Marina can also use center couplings to eliminate torsional loads on longer piers or for sections used to build angle attenuators.

SF Marina‘s typical anchoring for the SFBW1000 utilizes heavy chains coupled with shackles to the pontoon’s mooring ring and bridle rings, and to concrete anchors. The mooring rings are so heavily reinforced, one is strong enough to lift an entire 220-ton breakwater section. In use, when forces on the chain increase, as the coupling gets pulled downwards under load the total force causes the pontoons to be pulled together rather than apart, while the rubber cylinders maintain safe spacing.

With 20 licensed and regulated production locations spanning the globe, SF Marina can custom construct an entire wave attenuator system and deliver it anywhere in the world. Every SFBW1000 pontoon is manufactured in accordance with Eurocode SS-EN1992-1-1, inspected, tested in water, and certified. The result of SF Marina’s commitment to quality is why its floating concrete breakwater pontoons are internationally recognized as able to overcome the worst weather events on record and still be there after the storm.