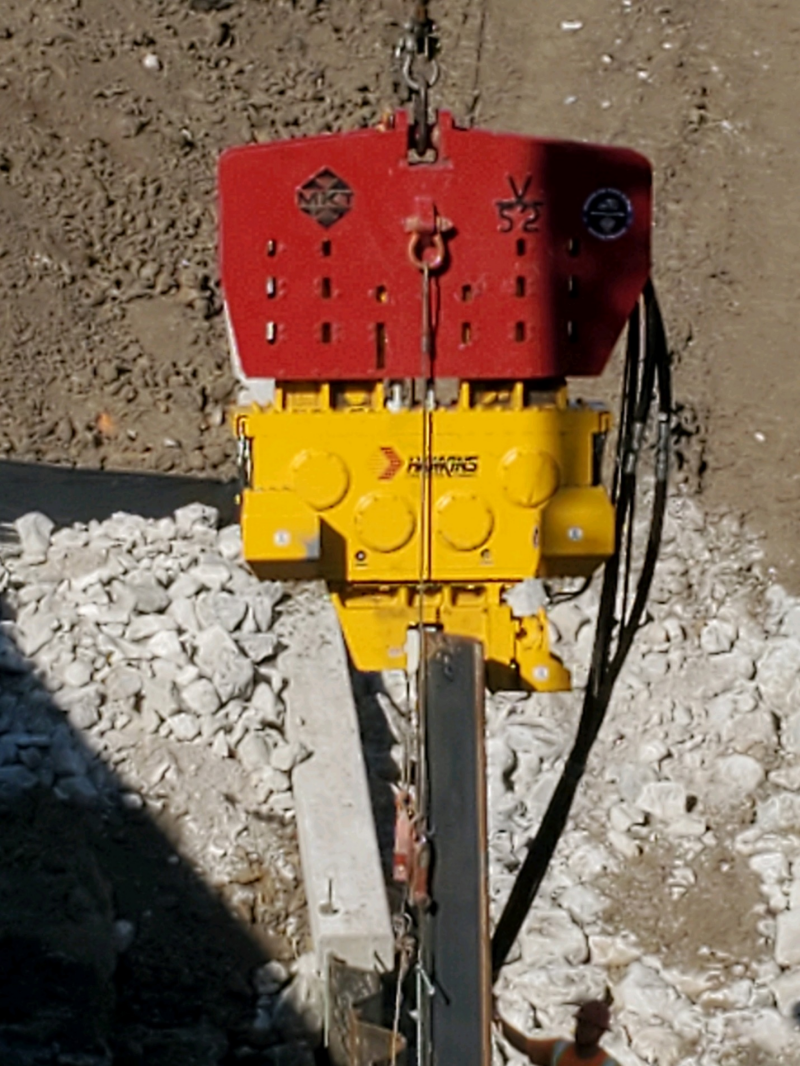

Custom Vibratory Pile Driving System: MKT & Hawkins Collaboration

MKT Manufacturing Inc. recently collaborated with Mississippi Valley Equipment and their customer, Hawkins Construction Company, on a custom designed V-52 / HP-700 Tier 4 vibratory pile driving system. Hawkins was in the market for a new large crane hung vibratory hammer and hydraulic power unit package but had certain design considerations they wanted built in to the new system. With nearly a century of pile driving experience and expertise, the Hawkins team, including their fleet manager, crane operator, and trainer, and seasoned service technician came up with 8-10 design considerations they wanted incorporated into the new system.

The MKT Team, who loves a challenge, happily accepted the task of customizing their current V-52/HP-700 designs. Nick Whisler, MKT’s Vice President and Engineer, was excited to gain invaluable insight directly from end users of MKT Equipment that have been driving pile likely before he was born. After a couple of weeks of collaboration between the two teams, the design changes were finalized and the build process was underway.

Some of the design considerations that are incorporated into the custom V-52 and HP-700 package include a removable lifting pin for easier rigging and maintenance, lifting eyes for picking pile, pivoting shipping stand so the hammer can be shipped fully assembled, warning lights and sirens on the power unit to alert if clamp or drive pressure is lost, and a custom paint job to match Hawkins’ current color scheme. The MKT Team is always looking for ways to improve their products and thought so highly of Hawkins’ suggestions that they are now part of MKT’s standard V-52/HP-700 Tier 4 package!