Complete Guide to Foundation Drilling Augers

View the complete article here.

Augers, each tailored to address specific soil conditions and project requirements, play a pivotal role in applications ranging from building foundations to bridge construction and environmental drilling. In this comprehensive guide—we will explore their various types, applications, as well as the critical factors influencing their selection. In addition, we will emphasize the importance of regular maintenance and provide troubleshooting tips to ensure the reliability, longevity, and safety of these indispensable tools.

Types of Augers

Foundation drilling applications rely on a range of specialized augers, each designed to tackle specific soil conditions and project requirements.

Continuous Flight Augers (CFA)

Continuous Flight Augers, often referred to as CFA augers, are one of the most commonly used tools in foundation drilling. They feature a single spiral blade that runs continuously along the length of the auger, creating a continuous flighting. CFA augers are typically hollow, allowing concrete to be pumped through the center during installation—forming a continuous concrete column.

Characteristics of continuous flight augers:

- Well-suited for soft to moderately dense soils.

- Minimal soil disturbance during drilling.

- High drilling speed and efficiency.

- Ideal for creating deep, continuous concrete piles used in building foundations and bridges.

Drilling Buckets

Drilling buckets are designed for drilling through hard and compacted soils, as well as rocks. These augers feature a cylindrical bucket with cutting teeth at the base, which excavates and retains soil or rock as it rotates.

Characteristics of drilling buckets:

- Suitable for drilling in rocky terrain and hard soil layers.

- Excellent for creating boreholes for caissons and drilled piers.

- Variations include rock buckets for drilling in challenging rock formations.

Hollow-Stem Augers

Hollow-stem augers are primarily used in environmental drilling and soil sampling applications. They feature a hollow center that allows for the collection of soil samples without removing the auger from the borehole.

Characteristics of hollow-stem augers:

- Ideal for soil sampling and environmental assessments.

- The hollow stem facilitates the extraction of soil cores for analysis.

- Typically used for environmental monitoring, geotechnical investigations, and groundwater sampling.

Helical Screw Piles

Helical screw piles, also known as helical piers or anchors, are innovative auger-based foundation systems. They consist of helical plates or flights welded to a central shaft, and they are screwed into the ground to provide support for structures.

Characteristics of helical screw piles:

- Excellent load-bearing capacity.

- Minimal vibration during installation, making them suitable for sensitive areas.

- Used in residential, commercial, and industrial foundation projects.

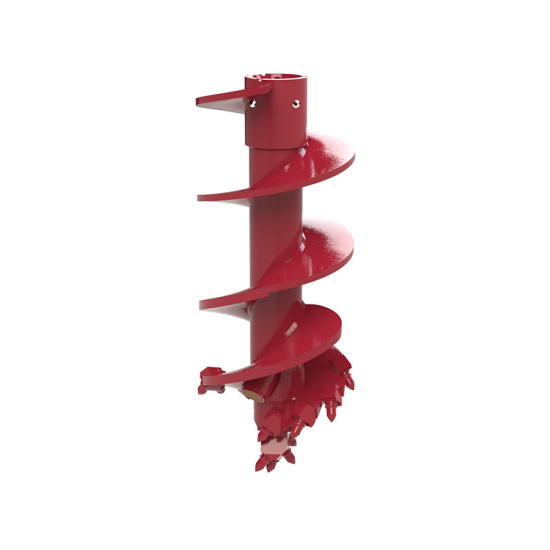

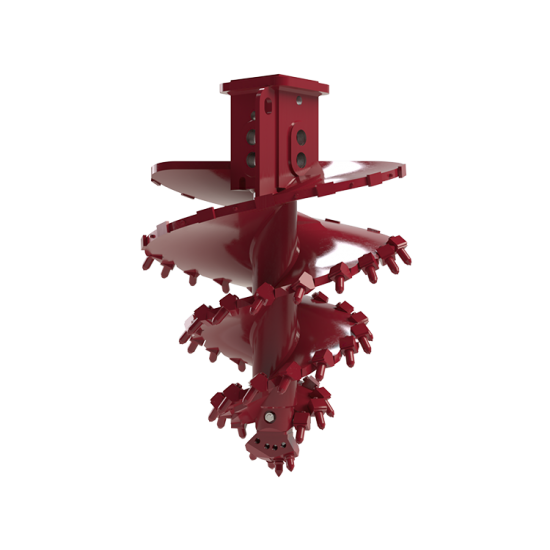

Rock Augers

Rock augers are heavy-duty tools designed explicitly for drilling in hard rock formations. They feature reinforced cutting teeth and robust construction to withstand the demands of rock drilling.

Characteristics of rock augers:

- Suited for drilling in challenging geological conditions.

- Typically used for creating boreholes for geological investigations and foundation construction in rocky terrain.

- Require high-powered drilling equipment.

Core Barrels

Core barrels are specialized augers used for collecting intact soil or rock core samples. They consist of a hollow tube with cutting bits at the base and a mechanism for retaining the core sample inside the barrel.

Characteristics of core barrels:

- Essential for geotechnical and environmental investigations.

- Provide undisturbed core samples for laboratory analysis.

- Used in assessing soil and rock properties for construction and engineering projects.

Factors Influencing Auger Selection

Selecting the appropriate auger for a foundation drilling project is a critical decision that can significantly impact the project’s success and efficiency. To make an informed choice, it’s essential to consider various factors that influence auger selection.

Soil Conditions

The soil composition at the project site plays a fundamental role in auger selection. Different auger types are better suited to specific soil conditions:

- Soft soils: Continuous Flight Augers (CFA) and hollow-stem augers are well-suited for drilling in soft, loose soils where stability is a concern.

- Hard soils and rocks: For drilling through hard soils or rocky terrain, bucket augers and rock augers are the preferred choices due to their robust cutting capabilities.

- Mixed soils: In areas with varying soil types, it may be necessary to switch between different auger types during the drilling process to address changing conditions.

Project Requirements

The specific requirements of your foundation drilling project are another crucial factor:

- Foundation type: Consider the type of foundation being constructed. Helical screw piles, for example, are commonly used for building foundations—while core barrels are employed for soil sampling and testing.

- Depth and diameter: Determine the required depth and diameter of the drilled hole. Some augers are better suited for deep drilling, while others excel in creating wider holes.

- Load-bearing capacity: If the foundation must support heavy loads, the auger choice should consider load-bearing capacity. Helical screw piles, with their high load-bearing capacity, may be preferable in such cases.

Equipment Compatibility

Compatibility with the drilling equipment being used is a practical consideration:

- Auger attachment: Ensure that the selected auger is compatible with the drilling equipment’s attachment mechanism, such as the auger drive or hydraulic system.

- Power requirements: Verify that the drilling equipment has sufficient power and torque to drive the chosen auger through the intended soil or rock types.

Choosing the Right Auger for a Specific Foundation Drilling Project

Choosing the right auger is a crucial step in the foundation drilling process. By considering soil conditions, project requirements, equipment compatibility, and seeking expert guidance—you can make an informed decision that maximizes the efficiency and success of your foundation drilling project.

Conduct a thorough soil analysis at the project site to understand the soil composition and conditions at various depths. This information is invaluable for selecting the most suitable auger type.

Seek advice from experienced foundation drilling professionals or geotechnical engineers who can provide insights into the ideal auger choice based on the site-specific factors.

Carefully review the project plans and specifications to determine the foundation type, depth, and diameter requirements. This will guide your auger selection.

Evaluate budget constraints and project timelines when selecting an auger. Some auger types may require more time or resources than others.

Ensure that the chosen auger is compatible with the drilling equipment available on-site. If necessary, acquire or rent the appropriate equipment.

Conduct test drilling, if feasible, to assess how the selected auger performs in the actual soil conditions. This can help identify any unforeseen challenges and refine the selection.

Auger Applications

Foundation drilling augers find a wide range of applications in construction and geotechnical engineering projects. Understanding these applications is essential for selecting the right auger for the job.

Building Foundations

Building foundations are among the most common applications for foundation drilling augers. They are used to create stable, load-bearing footings that support various structures—including residential homes, commercial buildings, and industrial facilities.

Continuous Flight Augers (CFA) and helical screw piles are often chosen for building foundation projects due to their efficiency, load-bearing capacity, and suitability for various soil conditions.

Bridge Construction

Augers play a vital role in bridge construction, where deep foundations are required to support the weight of the bridge structure. Augers are used to create boreholes for bridge piers and abutments.

Depending on the geological conditions at the site, bucket augers or rock augers may be employed to drill through hard or rocky terrain. The choice is influenced by the type of soil or rock encountered.

Retaining Walls

Retaining walls provide structural support to hold back soil or prevent erosion. Foundation drilling augers are used to create the foundation piles or caissons for retaining walls, ensuring stability and long-term durability.

The selection of auger type for retaining walls depends on the design specifications and soil conditions. CFA augers are commonly used for retaining wall foundations in softer soils, while bucket augers may be used in harder soils or rocky terrain.

Soil Sampling and Testing

Soil sampling and testing are essential for geotechnical investigations, environmental assessments, and construction projects. Augers equipped with soil sampling tools are used to collect intact soil cores for analysis.

Hollow-stem augers are specifically designed for soil sampling and environmental drilling applications. They allow for the extraction of undisturbed soil samples through the hollow center of the auger.

Environmental Drilling

Environmental drilling involves activities such as groundwater monitoring, soil remediation, and the installation of monitoring wells. Augers are used to create boreholes for these purposes, ensuring accurate data collection and environmental protection.

Hollow-stem augers are the preferred choice for environmental drilling due to their ability to collect soil and groundwater samples without contamination.

Auger Maintenance and Care

Proper maintenance and care of foundation drilling augers are essential to ensure their longevity, reliability, and safe operation. Neglecting maintenance can lead to equipment failures, project delays, and increased costs.

Importance of Regular Maintenance

Maintaining foundation drilling augers is crucial for several reasons…

Well-maintained augers are less likely to malfunction, reducing the risk of accidents and injuries on the job site.

Regular maintenance helps maintain optimal performance and efficiency, ensuring that projects are completed on time and within budget.

Preventative maintenance is often less expensive than repairing or replacing damaged augers.

Proper care extends the service life of augers, maximizing their return on investment.

Steps for Cleaning, Lubrication, and Inspection

To keep foundation drilling augers in top condition, follow these essential maintenance steps…

Cleaning:

- After each use—remove excess soil, rocks, and debris from the auger’s flighting—cutting edges, and other components.

- Use a pressure washer or high-pressure air to thoroughly clean the auger.

- Pay special attention to areas prone to buildup, such as the auger’s teeth or cutting blades.

Lubrication:

- Regularly lubricate moving parts—such as bearings, gears, and hydraulic components—according to the manufacturer’s recommendations.

- Ensure that all lubrication points are adequately greased to prevent excessive wear and friction.

Inspection:

- Conduct a visual inspection before and after each use to identify any signs of wear, damage, or loose components.

- Check for loose bolts, nuts, or fasteners and tighten them as needed.

- Inspect hydraulic hoses and connections for leaks or damage.

- Examine the auger teeth or cutting blades for signs of wear and replace them when necessary.

- Verify that safety features, such as guards and shields, are intact and functioning correctly.

Troubleshooting Common Issues and Solutions

Even with regular maintenance, issues may arise during auger operation. Here are some common problems and their potential solutions to anticipate:

If the auger experiences reduced drilling efficiency, it may be due to dull teeth or cutting blades. Sharpen or replace them as needed.

Hydraulic fluid leaks can occur at hose connections or seals. Address leaks promptly, replace damaged hoses or seals, and replenish hydraulic fluid.

Vibrations during operation can indicate misalignment or imbalance. Inspect the auger components for proper alignment and balance.

If the auger becomes stuck in the ground, stop operation immediately. Attempt to reverse the auger’s rotation to free it. If the problem persists, seek professional assistance to avoid equipment damage.

Unusual noises during drilling could indicate mechanical problems. Conduct a thorough inspection to identify and address the source of the noise.

Conclusion

From building foundations to bridge construction, retaining walls, soil sampling, and environmental drilling—the choice of auger type plays a pivotal role in the success of these applications. Moreover, recognizing the significance of regular maintenance—including cleaning, lubrication, and inspection—is paramount to ensuring the longevity, efficiency, and safety of these valuable tools. By understanding auger selection principles and embracing maintenance best practices, foundation contractors can maximize the potential of foundation drilling augers in their projects.

View the complete article here.

What are the key factors to consider when selecting an auger for foundation drilling?

Consider soil conditions, project requirements, equipment compatibility, and seek expert guidance for informed auger selection.

Why is regular maintenance important for foundation drilling augers?

Regular maintenance ensures optimal performance, reduces the risk of accidents, extends the auger's service life, and maximizes return on investment.