Cofferdams 101: History, Applications, Materials, Types, and More

View the complete article here

Among other obstacles faced in the construction process, water can be one of the most challenging and costly barriers during construction. With 71% of the earth’s surface covered in water, and new construction beginning every day, cofferdams are proving to be just as significant today as they were before the birth of Christ.

By definition, a cofferdam is a work area constructed and dewatered to temporarily provide dry land for construction of various types of structures.

In this article, we’re going to cover the different uses for cofferdams, the different types, the materials involved, the construction process, removal, and much more.

Cofferdams in History

The first recorded use of a cofferdam goes back to 539 BC. King Cyrus of Persia used cofferdams as a weapon of war. He diverted the Euphrates River with earthen cofferdams, which allowed his army to capture Babylon. Cofferdams were used by the Romans in 102AD to build Trajan’s Bridge. A cofferdam made of wood pilings allowed the Romans to build the bridge across the Danube River.

Cofferdam Uses

There are various construction scenarios where a cofferdam is necessary:

- Building a structure in a riverbed, seashore, or lake.

- Building in an area of course-grained soil, where deep excavations are required.

- Building below the groundwater table.

- Building when trenches would likely collapse – typically during deep excavations.

- To protect adjoining buildings or nearby structures.

- To remove a sunken vessel.

Cofferdam Requirements

There are several basic requirements of any cofferdam. It must be watertight. A cofferdam must remain standing against the pressure of existing or added water (such as a flood). Existing water includes water at, above, or below the groundwater table.

Cofferdam Materials

Cofferdams can be made from several different materials, such as earth, rocks, timber, steel, and concrete. If possible, the selected material should be relatively easy to dismantle and recycle to reduce construction costs.

Types of Cofferdams

There are various types of cofferdams, including:

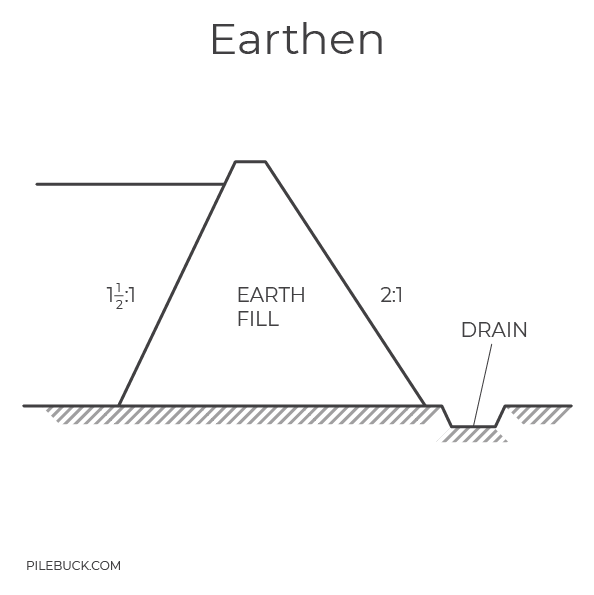

Earthen Cofferdams

Earthen Cofferdams

Earthen cofferdams are the simplest to construct but have somewhat limited use. An embankment made of earth is used to enclose the work area. Earthen cofferdams are best for areas with a low depth of water flowing at a low velocity. Typically, the top of the embankment is built approximately 1m above the water. Boulders may be used on the side slopes of the bank on the water side to prevent erosion.

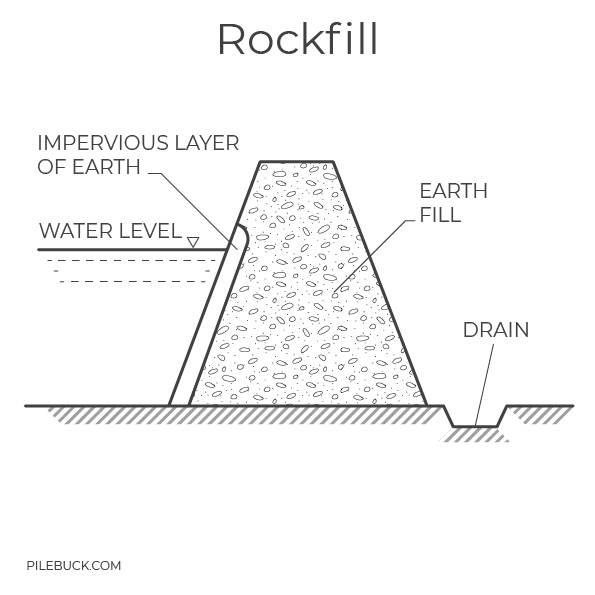

Rock-Filled Cofferdams

Rock-Filled Cofferdams

Similar to earthen cofferdams, rock-filled cofferdams have a rubble or stone embankment to surround the work area. A rock-filled cofferdam is still used in lower-depth water – perhaps 2m to 3m.

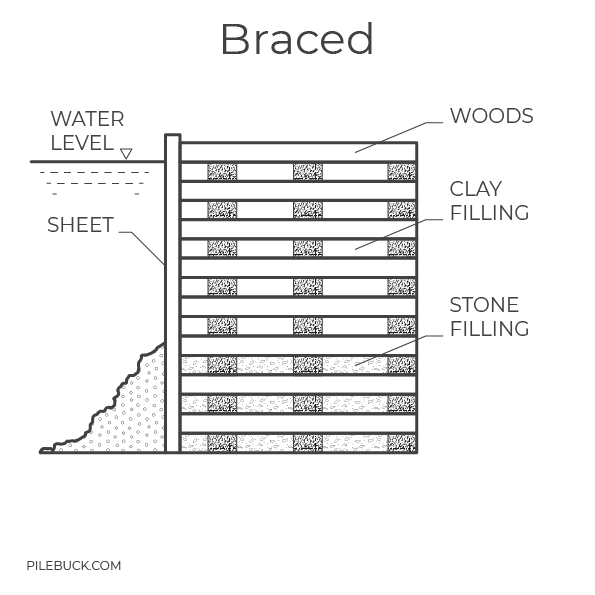

Braced Cofferdams

Braced Cofferdams

Braced cofferdams consist of a single wall of sheet pile that is supported by struts. This prevents the wall from collapsing inward. Braced cofferdams are typically used for smaller work areas. You may see this type of cofferdam used in the repair of bridge piers and abutments.

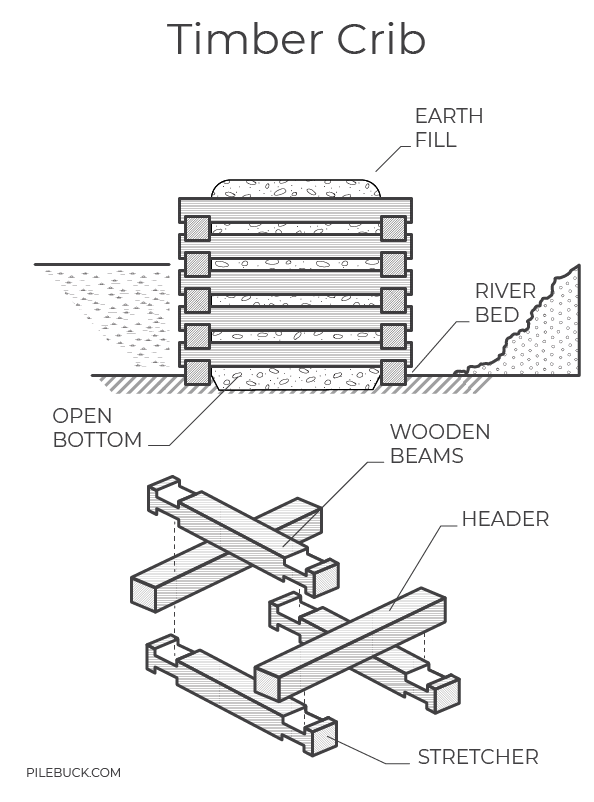

Timber Crib Cofferdams

Timber Crib Cofferdams

Timber crib cofferdams are made of a frame comprised of wooden beams. Horizontal and cross beams are laid in an alternate course. Timber crib cofferdams are left open at the bottom and filled in with either earth, gravel, or rock.

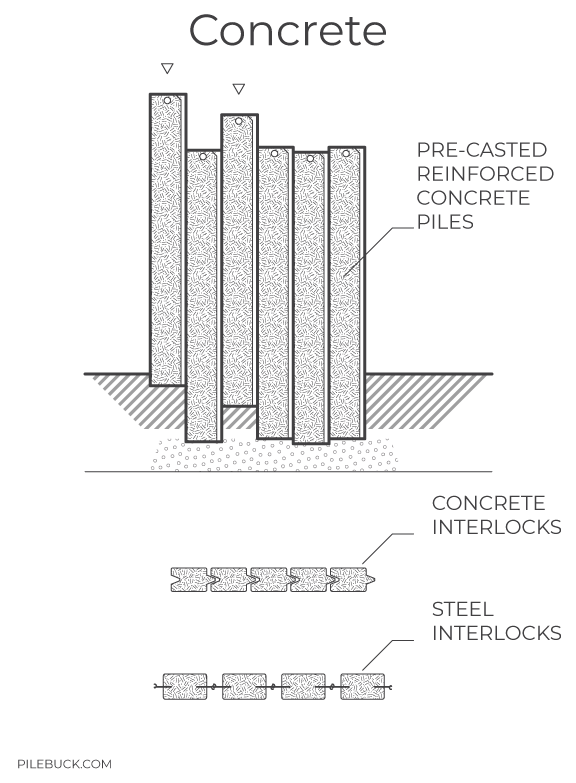

Concrete Cofferdams

Concrete Cofferdams

Concrete cofferdams are used when pile driving is problematic. This includes limited headroom, the need to reduce or eliminate vibrations, or where boulders embedded in the ground would split steel sheet piles. Concrete cofferdams are expensive, but the overall cost is reduced by making them part of the permanent structure. This type of cofferdam is typically used for smaller areas and are often built of pre-cast, reinforced cement concrete (RCC) piles.

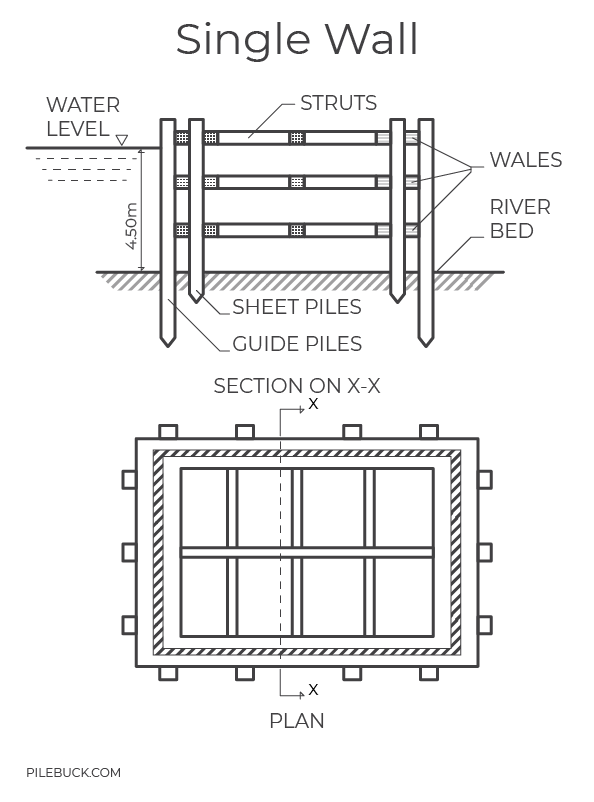

Single-Wall Cofferdams

Single-Wall Cofferdams

Single-wall cofferdams are used for small areas with a depth of water typically between 4.5 to 6 meters. Guide piles made of timber are driven deep into the riverbed – below the firm ground beneath it. The velocity of the flowing water determines the center-to-center spacing of the guide piles. Wales, also known as longitudinal runners, are bolted to the guide piles. Steel or wooden sheet piles are driven along the wales and then bolted to them. The sheets on both faces are braced using struts. Half-filled bags of sand are used to stabilize the single-wall cofferdam.

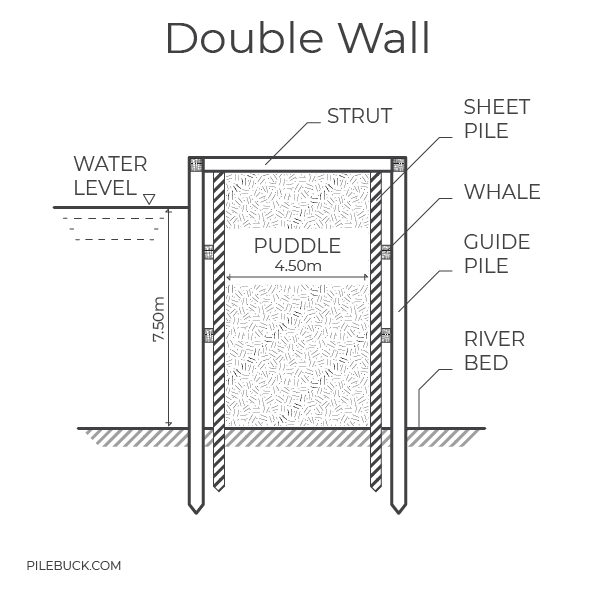

Double-Wall Cofferdams

Double-Wall Cofferdams

A double-wall cofferdam consists of two straight parallel walls made of sheet piling that are tied together. The space between the two walls is filled with soil. Double-wall cofferdams are used in water with a depth up to 12 meters.

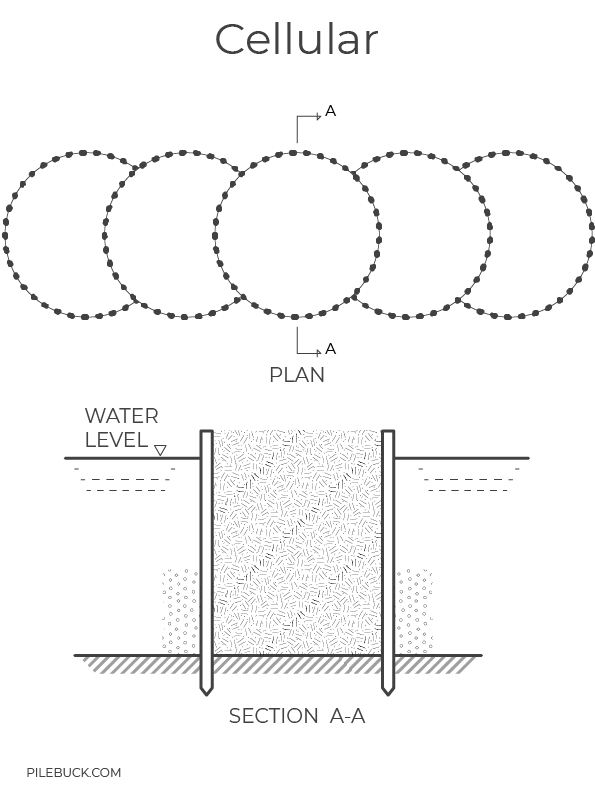

Cellular Cofferdams

Cellular Cofferdams

For large excavations, the use of cross-excavation bracing may not be feasible. Cellular cofferdams consist of interlocking steel plates designed to resist lateral forces without the need for bracing. There are two types of cellular cofferdams: diaphragm and circular. Diaphragm cellular cofferdams have circular arcs at the sides that are attached to straight diaphragm walls. Circular cellular cofferdams have large circular cells that are connected using circular cells that are a bit smaller. The cells of cellular cofferdams are filled – usually with earth or concrete. A waterproof membrane covers the cells and the whole cofferdam is placed and secured.

Cofferdam Construction Process

Most cofferdams are constructed using the following 12 general steps:

- Pre-dredge and level the area for the cofferdam.

- Drive temporary support piles.

- Temporarily install a bracing frame on the support piles.

- Install steel sheet piles.

- Drive sheet piles to grade.

- Block between bracing frame and sheets.

- Tie sheet piles at the top.

- Excavate, leaving the water inside the cofferdam.

- Install internal bracing as the water is removed progressively from the cofferdam.

- Drive piles as required.

- Install rock fill.

- Place tremie concrete seal.

Cofferdam Pressures

An engineer determines the best type of cofferdam to use. It needs to be of a sufficient size to meet the project requirements in the most economical way possible. The engineer uses standard calculations based on known and anticipated forces including hydrostatic pressure, soil loads, water currents, waves, ice, as well as seismic and accidental loads.

Emergency Response

With workers and equipment inside of what is essentially a deep, dry, well, you need to have an emergency response plan in place. There are several potential risks when working inside a cofferdam. Obviously, a flood event causes the cofferdam to fill up with water. But rock fissures and shifting soil conditions – even vessel traffic – can create unsafe conditions within the cofferdam. Any emergency response plan should include dewatering backups that are regularly inspected.

Cofferdam Removal

The cofferdam is meant to be a temporary structure. But you can’t just pull it out, chuck it out, and be done with it. Removal of the cofferdam must be planned in advance. A critical consideration is the impact of cofferdam removal on the structure that was built. In some cases, the sheet piles are sheared off and the bottoms are left in place. This is to avoid damaging foundation soils that could in turn damage the new structure.

Conclusion

Cofferdam construction is a tried-and-true technique that has allowed us to build bridges to connect communities within and between countries. Cofferdams are used to build dams to power our lives and allow commerce between international ports. The cofferdam is an old technology with a recorded history going back to 539 BC. Some of the materials from that time are still being used – earth, rock, and wood. The cofferdam continues to evolve with the use of different materials and construction methods.

For more detailed information pertaining to cofferdams, including our downloadable cofferdam book, visit PileBuck.com.

View the complete article here

What are the main types of cofferdams used in construction projects?

The main types of cofferdams include earthen, rock-filled, braced, timber crib, concrete, single-wall, double-wall, and cellular cofferdams, each suited for specific construction scenarios.

How is the cofferdam construction process carried out, and what are the key steps involved?

The cofferdam construction involves steps such as pre-dredging, installing temporary support piles, driving sheet piles, excavation, internal bracing, and filling, with a detailed process to create a dry work area for construction.

Earthen Cofferdams

Earthen Cofferdams Rock-Filled Cofferdams

Rock-Filled Cofferdams Braced Cofferdams

Braced Cofferdams Timber Crib Cofferdams

Timber Crib Cofferdams Concrete Cofferdams

Concrete Cofferdams Single-Wall Cofferdams

Single-Wall Cofferdams Double-Wall Cofferdams

Double-Wall Cofferdams Cellular Cofferdams

Cellular Cofferdams