Choosing, Designing, and Installing the Right Excavation Support System

View the complete article here.

Excavation support systems (ESSs), also known as shoring, are essential in modern construction. They provide the temporary or permanent support needed to keep soil and structures in place during the excavation process. Whether you are working on a small foundation or a massive infrastructure project—understanding how to select, design, and install the appropriate ESS is critical.

What are Excavation Support Systems (ESSs)?

Excavation support systems are designed to prevent soil movement and maintain the integrity of an excavation during construction. These systems are vital for ensuring worker safety, preventing structural damage, and managing groundwater. ESSs can be temporary, providing support until construction is complete—or permanent, offering long-term stability for a structure.

The types of excavation support systems include…

Temporary Shoring Systems

Temporary excavation support systems are used to stabilize the excavation site until the construction of a new structure is completed. Common types include:

- Soldier piles and lagging: This method involves driving vertical steel H-piles (soldier piles) into the ground at regular intervals, with horizontal lagging (wood or concrete) placed between them to retain soil.

- Braced excavations: For deeper excavations, bracing systems are often used. Horizontal or diagonal braces (struts) are installed to provide additional support against the pressure of the surrounding soil.

- Cantilever walls: Cantilever walls are designed to resist the lateral pressure of the soil using the strength of the wall itself, without external bracing or tiebacks.

Permanent Shoring Systems

Permanent systems are designed to last the lifetime of the structure. These systems must incorporate corrosion protection to withstand environmental conditions. Examples include:

- Secant/Tangent piles: Overlapping concrete piles (secant piles) or closely spaced piles (tangent piles) create a continuous wall. This method is often used in tight spaces or for groundwater cut-offs.

- Deep soil mix walls: This technique involves mixing soil with cement and other stabilizers to create strong, stable walls. It’s effective for permanent shoring, especially in poor soil conditions.

- Sheet pile walls: Steel sheet piles are driven into the ground to form a continuous barrier. Sheet piles are commonly used in marine construction and deep excavations.

Groundwater Management Considerations

In some cases, excavation support systems must also control groundwater. The presence of groundwater can weaken excavation walls, requiring systems designed to prevent water inflow. Secant piles, for example, are excellent at providing both structural support and groundwater cut-off.

Key Factors in Choosing an Excavation Support System

While choosing an excavation support system—factors such as soil conditions, load requirements, project duration, and groundwater control should be considered.

Soil Conditions

Soil type is one of the most significant factors influencing the choice of ESS. Cohesive soils, such as clay, behave differently from granular soils like sand or gravel. Cohesive soils can retain their shape longer, requiring less immediate support—whereas granular soils are prone to shifting and need robust shoring systems.

Load Requirements

Excavations near existing buildings, roads, or railways are subject to surcharge loads. These external loads can increase the pressure on the excavation walls, necessitating stronger support systems. It’s important to assess the type and magnitude of these loads during the design phase.

Project Duration

Temporary systems, such as soldier piles and lagging, are sufficient for short-term projects—but permanent shoring requires more durable solutions. If a structure will be in place for years, the excavation support must be built to last—often incorporating corrosion-resistant materials.

Groundwater Control

If groundwater is present, the excavation support system must account for water pressure. Secant and tangent piles, for example, are effective at both retaining soil and preventing groundwater infiltration.

Designing Excavation Support Systems

Designing an excavation support system is a complex process that involves multiple factors. The design must account for soil conditions, the depth of the excavation, and any nearby structures. The following should be considered…

Stiffness Requirements

The excavation depth and surrounding soil pressure determine the stiffness required from the support system. Deeper excavations often require stiffer support, which can be achieved through systems like bracing or tiebacks.

Lateral Support Methods

Lateral support is critical for deeper excavations. The most common methods include:

- Tiebacks: Anchors drilled into the surrounding soil or rock provide lateral support. Tiebacks are effective for deeper excavations and are often used with soldier piles.

- Soil nails: Soil nails are driven into the excavation walls to stabilize the soil. This method is often combined with shotcrete to create a retaining wall.

- Bracing systems: Bracing provides internal support by placing horizontal or diagonal struts across the excavation. This is common in urban settings where space is limited.

- Cantilever designs: For shallower excavations, cantilever walls may provide adequate support without needing external lateral reinforcement.

Corrosion Protection in Permanent Shoring

Permanent ESSs need to be designed with long-term durability in mind. Corrosion protection, such as epoxy coatings or galvanized steel, is essential for components exposed to moisture or harsh environmental conditions.

Installing Excavation Support Systems

Once designed, excavation support systems must be installed with care. The installation process typically follows these steps:

- Site preparation: Clear the site and ensure the excavation area is free from obstacles.

- Installation of vertical elements: Vertical support elements—such as soldier piles, sheet piles, or secant piles—are driven into place.

- Excavation and lateral support: As excavation progresses, lateral supports (such as tiebacks or braces) are installed at regular intervals to maintain the stability of the walls.

- Monitoring: Throughout the excavation, regular monitoring of the ESS is crucial to identify any signs of movement or distress in the system.

Maintenance and Monitoring of Excavation Support Systems

Regular maintenance and monitoring are critical for ensuring the continued stability of an ESS. For temporary systems, frequent inspections are necessary to ensure the supports remain in place throughout the excavation. Permanent systems, particularly those exposed to groundwater or corrosive environments, require ongoing maintenance to prevent degradation.

Signs that an ESS may need attention include:

- Cracks or deflections in walls.

- Shifting or movement in lateral supports.

- Water infiltration around excavation walls.

Proactive monitoring can help identify issues early, preventing costly repairs or failures down the line.

Case Studies

To better understand how excavation support systems (ESSs) work in practice, let’s take a look at a few scenarios where different types of ESSs were successfully implemented…

Case Study 1: Soldier Piles and Lagging for Urban Excavation

Project: Deep excavation for a multi-story office building in downtown Chicago.

Challenge: Limited space in a densely populated urban area with adjacent buildings and high traffic loads.

Solution: Soldier piles and lagging were chosen due to their flexibility and suitability for urban environments. The system provided lateral support without requiring extensive excavation of surrounding areas. Tiebacks were used to anchor the support system to stable soil behind the excavation, minimizing impact on nearby structures. Temporary bracing was also implemented to resist additional loads from construction traffic.

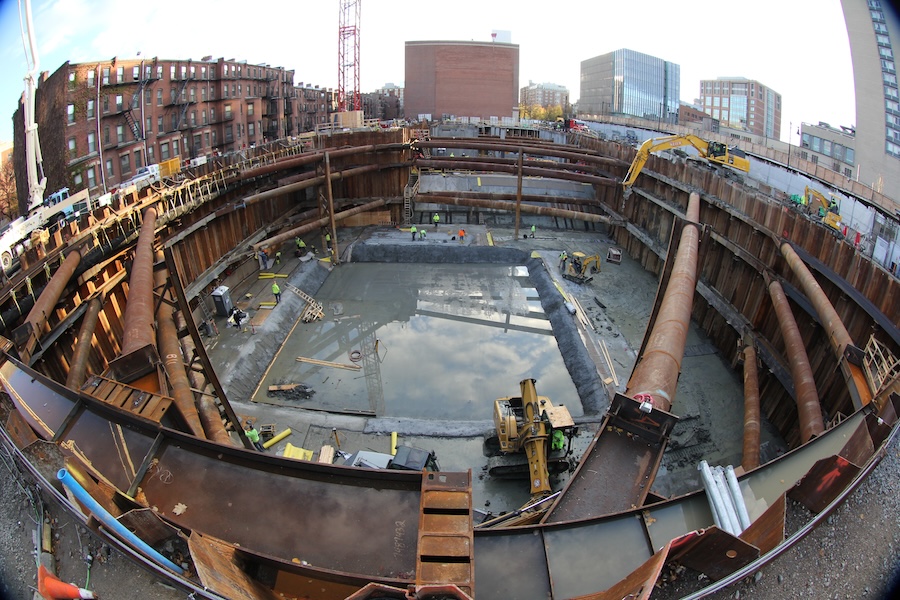

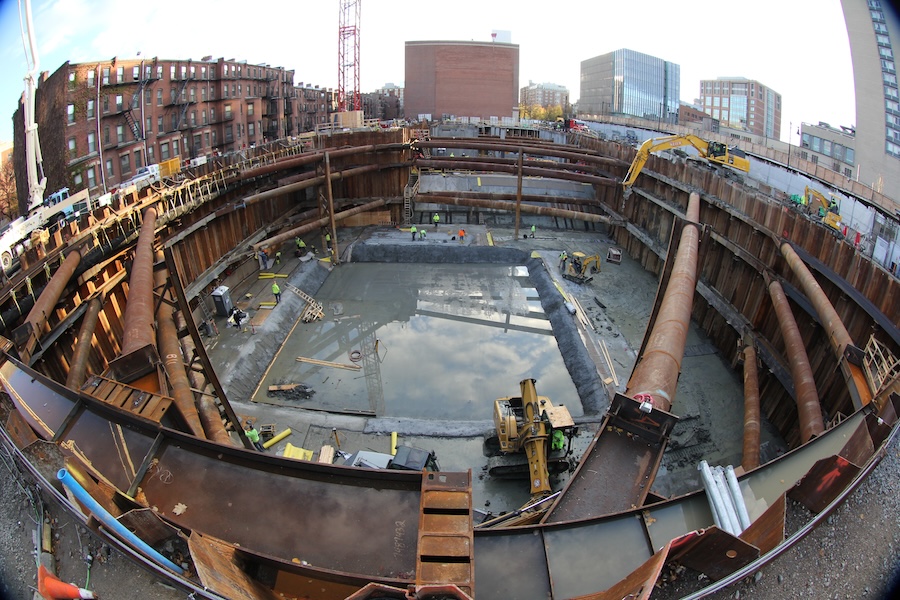

Case Study 2: Secant Pile Walls for Groundwater Management

Project: Construction of an underground parking structure in Boston, Massachusetts.

Challenge: The project was located in a coastal area with high groundwater levels, requiring an ESS that could handle both soil retention and groundwater cut-off.

Solution: A secant pile wall system was selected due to its ability to provide both structural support and effective groundwater control. Interlocking concrete piles created a watertight barrier that prevented groundwater intrusion, while also supporting the excavation walls. This minimized the need for dewatering systems, which would have added complexity and cost.

Case Study 3: Soil Nailing for Slope Stabilization

Project: Stabilization of a hillside for a highway expansion in California.

Challenge: The project required cutting into a steep slope with unstable soil, which presented a significant risk of landslides during construction.

Solution: Soil nailing was used to reinforce the slope and prevent soil movement. Steel bars were driven into the slope at regular intervals and secured with shotcrete to create a stable retaining wall. The system allowed for gradual excavation while ensuring the safety of workers and nearby infrastructure.

Case Study 4: Sheet Piling for Marine Construction

Project: Expansion of a marina in Miami, Florida.

Challenge: The project required excavation in a marine environment with soft soil and the need to protect against tidal influences.

Solution: Steel sheet piles were driven into the soft soil to form a continuous barrier around the excavation site. The sheet pile wall provided the necessary support for excavation while also preventing water from entering the work area. Additionally, the use of steel with corrosion-resistant coatings ensured the longevity of the system—making it suitable for permanent installation in a saltwater environment.

View the complete article here.

What are excavation support systems (ESSs)?

ESSs are structures designed to prevent soil movement and maintain excavation stability, either temporarily or permanently.

How does groundwater affect the choice of an ESS?

Groundwater requires ESSs like secant piles, which provide both soil support and groundwater cut-off.