Best Practices for Using Hoists in Marine Construction

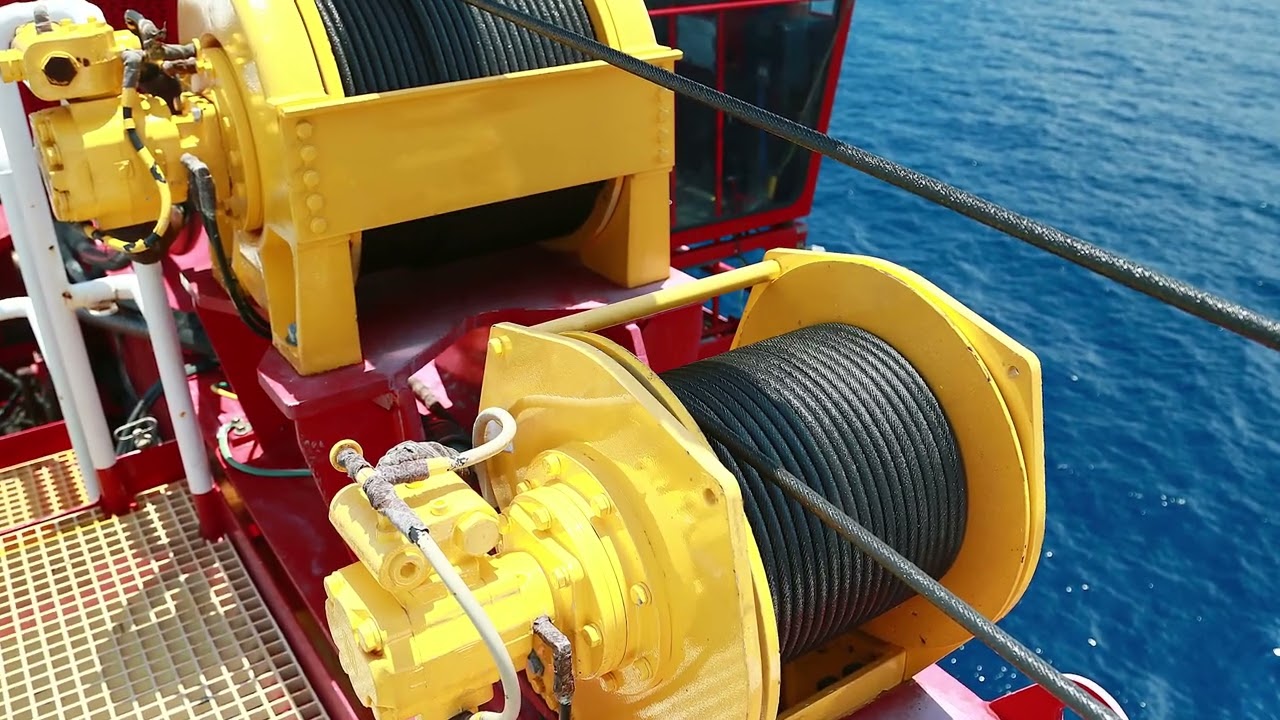

In marine construction, lifting operations demand more than just brute strength they demand consistency, control, and safety. A properly specified and maintained hoist system delivers dependable performance even in high-corrosion environments, ensuring every lift is executed with confidence.

Few environments are as demanding as the sea. Saltwater, humidity, and constant motion create extreme stress on equipment. A hoist built for marine use must resist corrosion, endure constant load cycles, and perform reliably through varying temperatures and conditions.

Selecting the Right Hoist

Every marine project is unique, and selecting the right hoist begins with understanding the type of work, load range, and operational environment. A dredging project, for example, demands a continuous-duty hoist with high torque and smooth line speed control, while fishing operations may require repetitive cycle performance with rapid lifting and lowering.

The BG and GH Series hoists from Arrowhead Winch are designed specifically for these kinds of challenges, offering planetary gear systems that combine compact size with high efficiency. Hydraulic configurations are ideal for floating or offshore installations where power reliability and environmental sealing are crucial.

Safety systems must always be a top priority. Features like load-holding brakes, overload protection, and emergency release systems protect both operators and equipment. For optimal performance, the hoist’s rated capacity must exceed the maximum anticipated working load, accounting for shock factors and vessel motion.

Installation Best Practices

Even the best hoist can fail if improperly installed. The mounting structure must be strong, level, and reinforced to handle both static and dynamic forces. For barge or dredge applications, hoists should be mounted on vibration-dampened bases that distribute loads evenly and prevent misalignment.

Every mounting bolt, joint, and weld must be sealed to block saltwater intrusion. Use marine-grade fasteners and non-corrosive sealants throughout. Before commissioning, conduct alignment checks between the hoist drum and the load path to avoid side loading, which accelerates wear on bearings and cables.

Finally, perform full pre-commissioning tests verifying brakes, limit switches, and control functions under light loads before putting the system into full service. A controlled test run ensures the hoist can manage real-world forces safely and predictably.

Safe Operation on Site

Operating a hoist at sea requires discipline, awareness, and training. Crews must be familiar with load ratings, operating speeds, and emergency procedures. Regular pre-use inspections are critical: check wire ropes, hooks, and drums for corrosion, fraying, or deformation.

Personnel must remain clear of the hoisting line and drum area during operation, especially under tension. A snapped rope can release enormous energy, posing serious risk to nearby workers. Operators should maintain smooth, consistent line speeds and avoid sudden stops or jerks that can create shock loads particularly on floating or moving platforms.

When possible, integrate load monitoring systems to provide real-time feedback, preventing overloading and ensuring that each lift stays within safe limits.

Maintenance and Inspection

Marine conditions accelerate corrosion and wear, so proactive maintenance is essential. Inspect all hoist components routinely, paying special attention to brakes, gear housings, hydraulic lines, and cable terminations.

Lubricate with marine-grade greases that resist washout but don’t attract debris. Check hydraulic systems for leaks, maintain fluid levels, and ensure filters are clean. Electrical components and control boxes should remain sealed and dry, with regular checks for insulation damage or corrosion on terminals.

Wire ropes must be rinsed with fresh water after each operation and treated with corrosion-resistant lubricant. Replace any rope showing kinks, broken wires, or flattened strands. Keep a detailed maintenance log tracking inspections, repairs, and component replacements helps predict wear patterns and ensures compliance with safety standards.

Integrating Hoists into Marine Construction System

A hoist rarely operates in isolation. In most marine construction setups, hoists work in tandem with cranes, spud systems, and winches to coordinate complex lifting and positioning tasks. Proper integration ensures even load distribution and synchronized motion across all systems.

Use fairleads, sheaves, and guide rollers to maintain correct rope alignment and prevent side stresses on the drum. When multiple hoists or winches operate simultaneously such as on dredging platforms install load monitoring systems and assign a single operator or control system to coordinate all movements.

Routine joint inspections between hoists and related machinery reduce mechanical conflicts, ensuring smoother, safer performance across the deck.

The marine environment will always be unpredictable, but your equipment shouldn’t be. A well-chosen, properly installed, and regularly maintained hoist ensures that every lift is precise, safe, and reliable.

Hydraulic or continuous-duty hoists with corrosion resistance and smooth load control are ideal for marine environments.

Regular inspections, lubrication with marine-grade greases, and corrosion protection keep hoists reliable and safe at sea. What type of hoist is best for marine construction?

How can hoists be safely maintained in harsh marine conditions?