Beam Beveling and Steel Fabrication Techniques for Durable Marine Structures

Marine structures such as piers, quay walls, offshore platforms and pile foundations face relentless challenges—wave impact, corrosion, vibration and load cycling. Ensuring these steel components endure such forces depends heavily on fabrication quality. Precision in cutting, edge preparation, beveling and welding directly determines a structure’s durability. One fabrication step that often defines weld integrity is beam beveling, which enables full penetration welds and cleaner, longer-lasting joints. This article explores beveling’s role in marine steel fabrication and examines modern tools and techniques that help engineers build stronger, more reliable structures.

The Importance of Edge Preparation

Understanding Beveling in Structural Fabrication

Beveling is the controlled removal or shaping of a beam or plate edge to create a specific angle for welding. It ensures proper weld penetration and alignment by allowing molten metal to fuse completely through the joint. In heavy fabrication, accurate beveling reduces defects and limits the need for grinding or filler passes. Using advanced beam beveling equipment allows fabricators to create consistent bevel geometry, improving fit-up quality and weld appearance while minimizing rework.

The Marine Environment’s Demands on Fabricated Steel

Steel used in marine environments must resist both corrosion and fatigue. Incomplete fusion or trapped slag at weld joints can create weak points that crack under stress or corrode over time. Properly beveled edges allow uniform welds with fewer voids and better coating coverage. Smooth transitions between welded parts also help marine coatings adhere more effectively, providing stronger protection against saltwater attack.

Fabrication Workflow Efficiency

In marine projects, every hour saved in the field matters. Shops that integrate beveling early in fabrication workflows reduce delays at the dock or platform. Field beveling solutions that allow operators to perform precise cuts without external power sources have become valuable assets. These systems make it possible to achieve shop-level precision in outdoor conditions, supporting tight project timelines and quality control requirements.

Fabrication Techniques for Marine-Grade Steel

Structural Beam Fabrication

H-beams, wide-flange sections and welded plate girders form the backbone of most marine structures. Welded beam fabrication involves cutting, coping, drilling and edge preparation before assembly. Each of these steps contributes to proper alignment and strength. If a bevel is inconsistent or misaligned, welds can develop stress concentrations that shorten the beam’s service life.

Beveling Methods and Best Practices

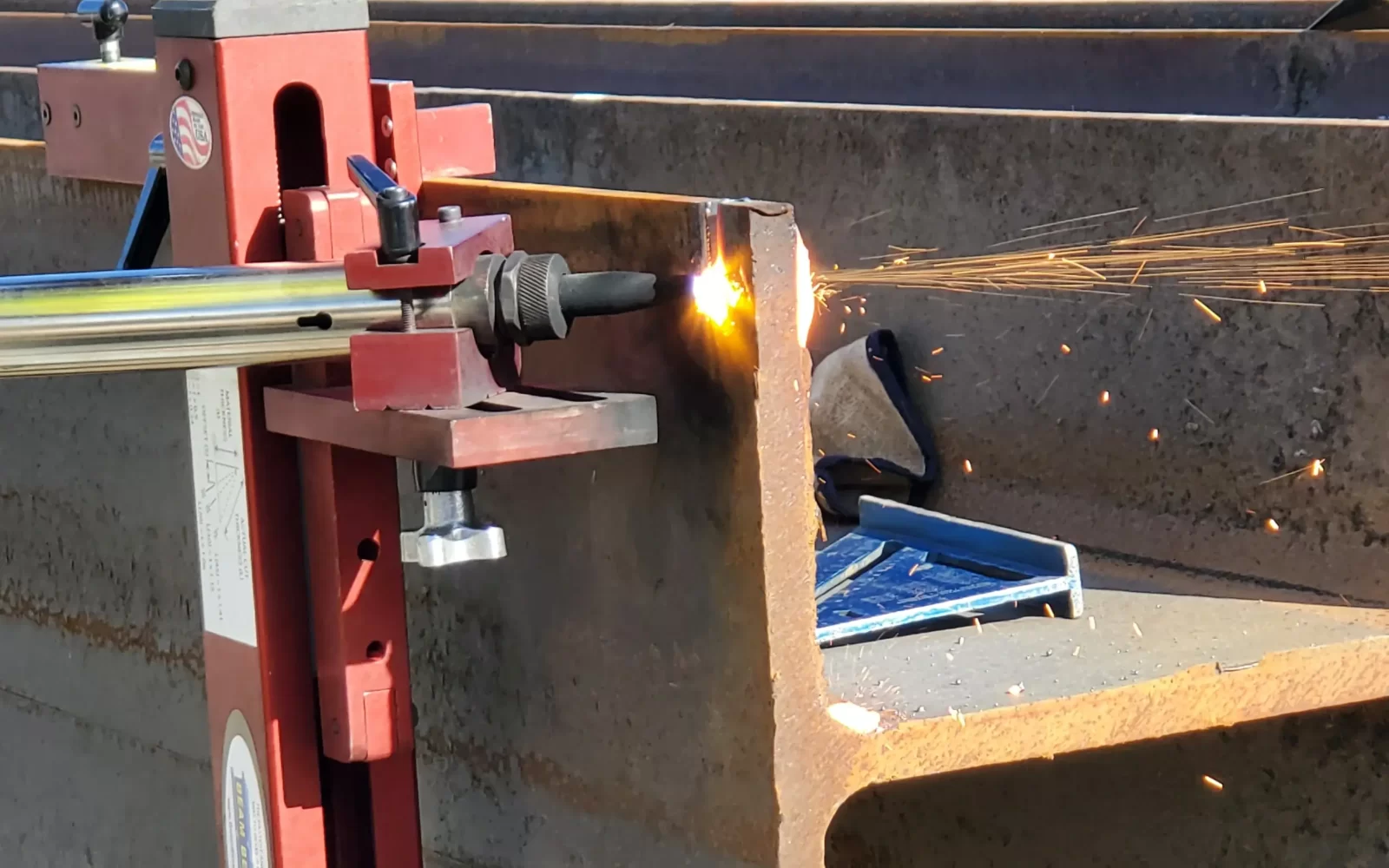

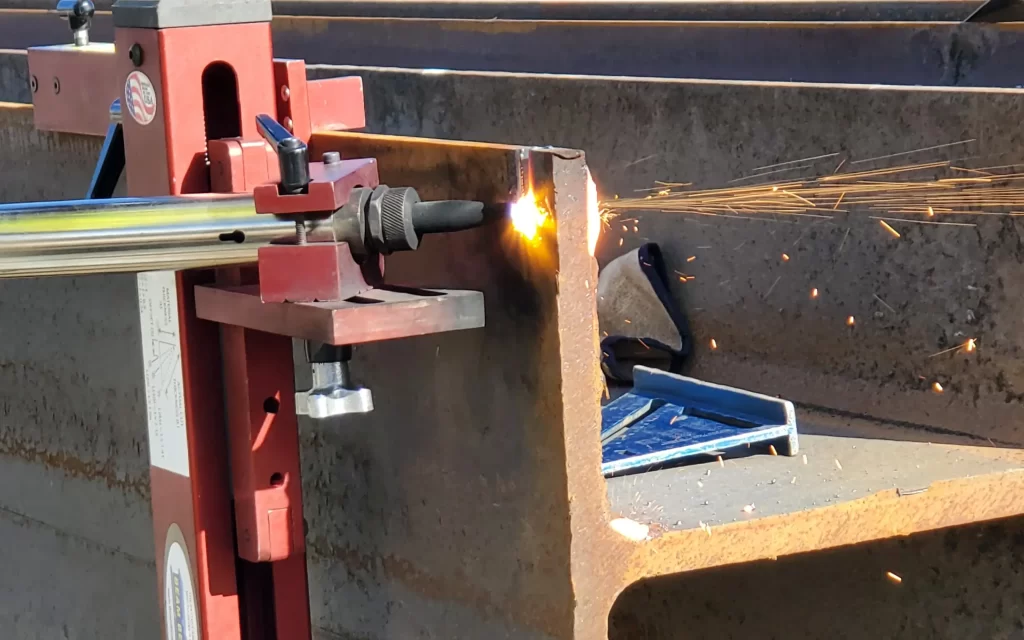

Several beveling methods are common in structural fabrication, including mechanical milling, plasma cutting and grinding. Mechanized systems are preferred for large projects because they deliver accuracy and repeatability across multiple beams. Portable beveling machines are widely used on site to produce uniform weld grooves in confined work areas. They eliminate much of the manual grinding effort and deliver smoother edges with minimal heat distortion, making them well suited for beams used in marine splices or stiffener connections.

Integration with Cutting and Assembly

Efficient fabrication integrates cutting, beveling, and assembly rather than treating them as separate stages. When a beam or flange is cut to length, the bevel can be applied immediately, maintaining correct alignment for welding. Fabricators who adopt beam cutting and weld preparation tools in a single workflow save both labor and setup time. The result is cleaner joints, reduced distortion, and consistent fit during marine installation.

Achieving Durability Through Quality and Finishing

Welding Standards and Inspection

After beveling, weld quality becomes the next critical step. Marine projects often require full-penetration welds that meet codes such as AWS D1.1 or ISO 5817. Without proper bevel geometry, achieving these specifications is difficult. Controlled bevel angles and groove dimensions ensure uniform heat distribution and solid fusion. Many fabrication shops include beveling as a defined part of their weld-prep procedure to ensure compliance with these standards.

Surface Protection and Corrosion Resistance

Post-fabrication finishing is essential for structures exposed to seawater. A clean bevel promotes coating adhesion and eliminates crevices where moisture can accumulate. Galvanizing, epoxy coatings or metallizing all depend on smooth weld transitions. When beveling is uneven, paint or zinc layers can thin at the joint, creating early corrosion points. Smoothly beveled and welded joints therefore extend service life and reduce maintenance costs for marine operators.

Reducing On-Site Rework

On-site conditions are unpredictable humidity, tides and limited crane access often complicate welding operations. Delivering prefabricated, beveled components directly to the job site reduces risk and cost. Efficient beam beveling methods used in fabrication shops minimize field grinding and adjustment, leading to faster fit-ups and safer working conditions. This integration between shop precision and field assembly is a major factor in achieving reliable marine performance.

Best Practices for Beveling Workflow in Marine Projects

Planning and Design

Engineering drawings should define bevel geometry from the start. Early coordination between designers and fabricators avoids mismatches between field and shop expectations. Properly specified bevel angles, root faces and weld gaps ensure that the structural design intent is carried through production. Including these details in the planning stage prevents costly rework later in the project.

Controlled Execution in Fabrication Shops

Beveling large beams for marine structures requires steady control and repeatability. Mechanical beveling provides better accuracy than manual grinding, especially on long flange or web surfaces. Equipment that clamps securely to the beam and maintains angle consistency allows shops to handle complex splices with confidence. Mechanical beveling systems for structural steel also enhance worker safety by reducing vibration and fatigue while achieving clean, burr-free edges.

Field Assembly and Final Welding

When prefabricated beams arrive on site with properly beveled edges, welders can focus on alignment and fusion rather than reshaping the joint. This leads to shorter welding times and higher consistency in joint quality. For marine applications where inspection and certification standards are strict, accurate bevels play a decisive role in passing quality checks. The combination of precise preparation and controlled welding ultimately determines how well a structure withstands its harsh environment.

Beam beveling may appear to be a small step in the fabrication process, but its influence on weld strength and long-term durability is enormous. In marine construction, where steel elements endure constant exposure to moisture, movement and mechanical stress, the quality of every weld counts. Modern fabrication workflows that integrate cutting, beveling and welding deliver stronger joints, smoother finishes and better corrosion protection.

Using innovations in beam fabrication such as portable mechanical beveling equipment helps bridge the gap between shop precision and field practicality. As fabrication technology advances, marine contractors who invest in accurate edge preparation will see measurable returns in reduced rework, improved performance and longer structural life. In the demanding world of marine engineering, precision in every bevel translates directly into resilience beneath the waves.

Beam beveling ensures full-penetration welds and clean joints, reducing fatigue and corrosion in steel exposed to waves, vibration, and saltwater.

They deliver precise, repeatable edge preparation in the shop or field, minimizing grinding, rework, and on-site welding delays. Why is beam beveling critical for marine steel structures?

How do modern beam beveling techniques improve marine fabrication efficiency?