Anchor Drilling Essentials: Tools, Chairs, and Accessories for Deep Foundations Applications

Anchor drilling plays a critical role in modern deep foundations and geotechnical construction, supporting everything from retaining systems to slope stabilization and tiedown anchors. These operations demand precision, load control, and consistent installation quality, particularly in challenging subsurface conditions. The success of anchor drilling projects depends not only on drilling techniques, but also on the selection and integration of specialized tools, structural supports, and jobsite accessories that ensure safety and performance.

As infrastructure projects expand into more complex environments, contractors rely on advanced anchor drilling equipment, modular support systems, and purpose-built accessories to improve accuracy, reduce downtime, and maintain structural integrity throughout the drilling process.

Anchor Drilling Applications in Deep Foundations

Anchor drilling is commonly used in deep foundations to transfer tensile and compressive loads from structures into stable soil or rock layers. These systems are essential in applications such as retaining walls, bridge abutments, excavation support, dams, and foundation underpinning. In many cases, anchors are installed at precise inclinations and depths to counteract lateral earth pressures or uplift forces.

The increasing use of anchors in urban construction, marine environments, and transportation infrastructure has driven demand for reliable anchor drilling systems capable of operating in restricted spaces and variable ground conditions. Contractors often integrate anchor drilling operations alongside pile driving, micropiling, and soil nailing to create hybrid foundation solutions that balance cost, performance, and constructability.

Core Anchor Drilling Tools

Drilling Rigs and Drive Systems

Anchor drilling operations typically begin with specialized drilling rigs designed to handle high torque, controlled feed pressure, and angled drilling requirements. These rigs may be mounted on crawler carriers, wheeled platforms, or modular frames depending on site access and mobility needs. Hydraulic drive systems are commonly used due to their ability to deliver consistent rotational force while accommodating variations in ground resistance.

Modern anchor drilling setups frequently integrate automated controls that regulate rotation speed, feed rate, and flushing pressure, improving borehole stability and reducing tool wear. The use of purpose-built anchor drilling equipment allows contractors to maintain borehole alignment and depth accuracy, which are critical factors in achieving designed anchor capacities. Many projects also depend on adaptable drilling systems sourced through trusted suppliers of anchor drilling equipment to match site-specific demands.

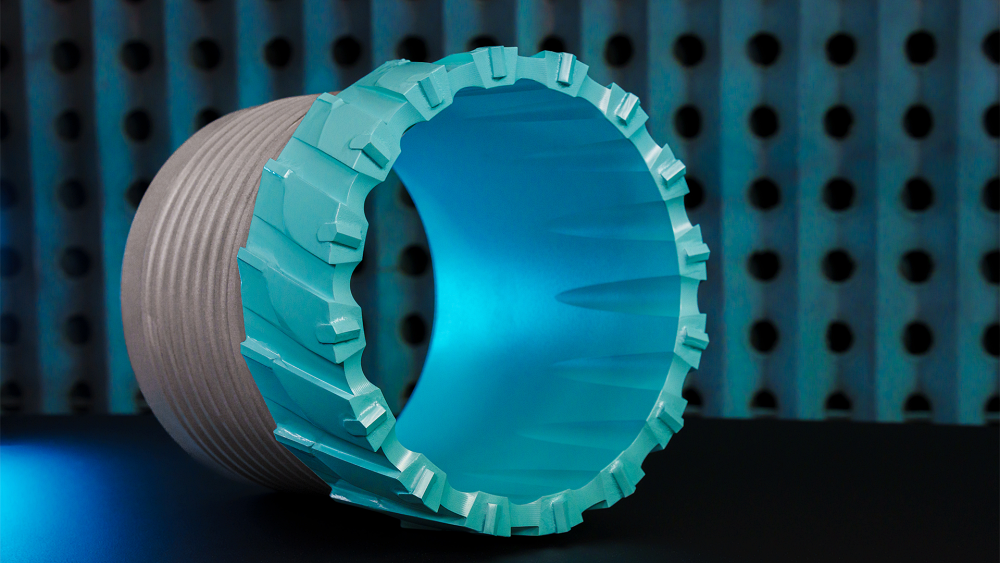

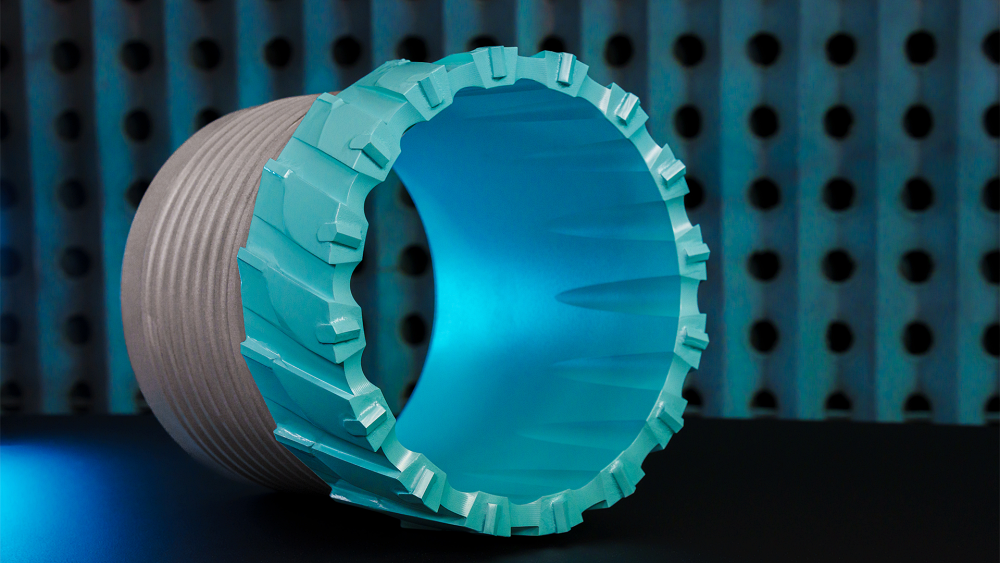

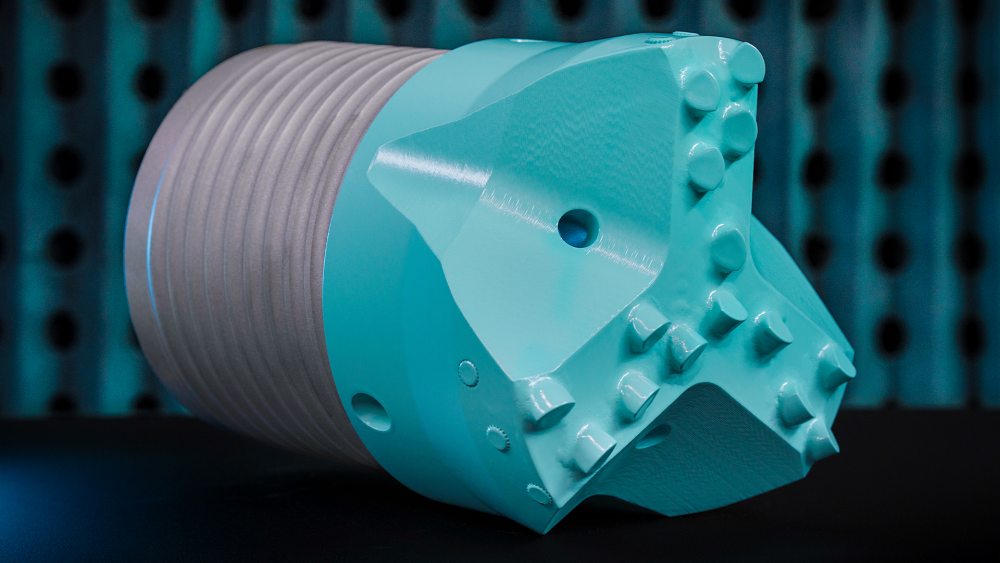

Drill Rods, Bits, and Tooling

Drill rods and bits form the direct interface between the drilling system and the ground. These components must withstand high torsional loads, abrasive soils, and repeated impact forces. Threaded connections are designed to transmit torque efficiently while minimizing the risk of loosening during operation.

Drill bits for anchor drilling vary depending on ground conditions and include carbide-tipped bits for rock, drag bits for cohesive soils, and hybrid designs for mixed strata. Proper selection of rods and bits directly influences penetration rates, borehole quality, and overall drilling efficiency. Consistent maintenance and inspection of tooling are essential to prevent failures that could compromise anchor installation quality.

Anchor Drilling Chairs and Structural Supports

Purpose and Load Control

Anchor drilling chairs serve as structural supports that stabilize the drilling assembly during anchor installation. These components help maintain drilling alignment, resist reaction forces, and distribute loads into the surrounding structure or ground. In many applications, drilling chairs are mounted to existing walls, slabs, or temporary frames to provide a stable reference point for drilling operations.

Proper load control is especially important in deep foundation applications where anchor angles and embedment depths must meet strict engineering specifications. Drilling chairs help ensure that drilling forces do not cause unintended movement or deflection that could alter anchor geometry or compromise structural performance.

Design and Installation Considerations

Drilling chairs are typically designed to accommodate different anchor diameters, drilling angles, and load capacities. Modular designs allow contractors to adjust configurations based on project requirements, improving adaptability across multiple anchor types and site conditions. Installation accuracy is critical, as misalignment at the chair level can propagate through the drilling process and affect final anchor performance.

In confined or elevated work areas, drilling chairs also enhance jobsite safety by providing secure attachment points and reducing reliance on improvised supports. Their use has become increasingly common in complex foundation projects where precision and repeatability are essential.

Accessories Supporting Anchor Drilling Operations

Centralizers and Spacers

Centralizers and spacers are used to maintain proper positioning of anchor tendons or bars within the borehole. These accessories help ensure uniform grout coverage around the anchor, which is necessary for load transfer and corrosion protection. Centralization is especially important in long anchors or inclined installations where gravity can cause components to shift during placement.

The use of engineered centralizers improves installation consistency and reduces the risk of voids or weak zones in the grout column. This contributes directly to the long-term durability and performance of anchor systems in deep foundations.

Grouting Equipment and Accessories

Grouting is a critical phase of anchor installation, providing bond strength between the anchor and surrounding ground. Grouting equipment typically includes pumps, hoses, mixers, and injection accessories designed to deliver controlled grout flow at specified pressures. Proper grout placement helps fill annular spaces, stabilize boreholes, and protect anchor components from environmental exposure.

Accessories such as packers and valves are used to isolate grout zones and manage injection sequences. These tools allow contractors to tailor grouting procedures to varying soil and rock conditions, ensuring effective load transfer and minimizing material waste.

Alignment and Monitoring Tools

Accurate alignment and monitoring are essential throughout anchor drilling operations. Tools such as inclinometers, laser guides, and depth measurement systems help verify borehole orientation and length during drilling. Monitoring equipment also supports quality control by documenting installation parameters and identifying deviations from design specifications.

The integration of alignment and monitoring accessories supports compliance with project requirements and reduces the likelihood of rework or corrective measures. These tools have become standard components of professional anchor drilling setups in deep foundation projects.

Integration with Deep Foundation Systems

Anchor drilling rarely occurs in isolation and is often integrated with other foundation elements such as piles, retaining walls, and ground improvement systems. Coordination between anchor installation and related construction activities is essential to avoid conflicts and maintain structural continuity.

In marine and waterfront projects, anchor drilling systems must also account for tidal forces, water pressure, and corrosion risks. Accessories and support systems designed for harsh environments help extend service life and maintain performance in demanding conditions. Contractors often rely on established anchor drilling systems and accessories to ensure compatibility across different foundation components.

Advancements in Anchor Drilling Technology

Technological advancements continue to influence anchor drilling practices, with improvements focused on efficiency, safety, and environmental performance. Developments in high-strength materials, modular tooling, and automated controls have enhanced drilling accuracy and reduced operator fatigue.

Data-driven monitoring systems are increasingly used to record drilling parameters and support documentation requirements. These innovations help contractors optimize anchor installation processes while meeting evolving regulatory and engineering standards. As deep foundation projects grow in scale and complexity, the demand for advanced anchor drilling tools and accessories continues to rise.

Anchor drilling remains a cornerstone of deep foundation construction, providing reliable load transfer and structural support across a wide range of applications. The effectiveness of anchor systems depends on the careful selection and integration of drilling tools, chairs, and accessories that support precision, stability, and durability.

By investing in well-designed anchor drilling systems and compatible accessories, contractors can improve installation quality, reduce operational risks, and meet the demanding requirements of modern foundation projects. As industry practices evolve, the continued refinement of anchor drilling equipment and support technologies will play a vital role in advancing deep foundation engineering.

Anchor drilling installs tension and compression anchors to stabilize structures and resist lateral or uplift loads.

They maintain alignment, load control, and proper grout coverage to ensure anchor performance and durability. What is the purpose of anchor drilling in deep foundation projects?

Why are drilling chairs and centralizers important in anchor installation?