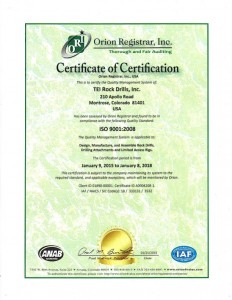

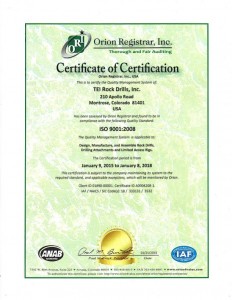

TEI Rock Drills Awarded ISO 9001:2008

TEI Rock Drills has recently been awarded an ISO 9001:2008 certification to “design, manufacture and assemble rock drills, drilling attachments and limited access rigs.” For those not familiar with what an ISO certification is and why it is important let me explain. ISO is the International Organization for Standardization a voluntary group headquartered in Geneva, Switzerland. This group develops international standards used by 164 member countries to facilitate world trade by providing common standards between member nations. The goal is to “develop a quality management system that will consistently provide product that meets customer and regulatory requirements.”

TEI Rock Drills has recently been awarded an ISO 9001:2008 certification to “design, manufacture and assemble rock drills, drilling attachments and limited access rigs.” For those not familiar with what an ISO certification is and why it is important let me explain. ISO is the International Organization for Standardization a voluntary group headquartered in Geneva, Switzerland. This group develops international standards used by 164 member countries to facilitate world trade by providing common standards between member nations. The goal is to “develop a quality management system that will consistently provide product that meets customer and regulatory requirements.”

Just as it sounds this is a long process with many reviews and inspections. Some companies choose not to bother with ISO certification and feel that it is a waste of time. TEI however, has always been committed to being the very best at what we do and ISO is part of that.

The process of acquiring ISO certification took almost two years and was spearheaded by TEI production manager, Donna Rousse. Donna did her best to hold monthly meetings with all department heads to make sure that things were on track. Processes had to be documented, edited and organized for everything from brochures to waste steel removal. “Although these processes and meetings were at times difficult the benefit to TEI in the end was invaluable” says Rousse.

One of the big reasons for TEI obtaining ISO certification is the ability to work directly with other manufacturers. TEI supplies drill rigs and components to OEM (original equipment manufacturer) suppliers, The United States Military and partners for special projects with contractors. The ISO certification means that all of the parties involved are “equal” and use the same documentation method enabling the most efficient integration of all the pieces. TEI can email a print to another manufacturer and they can incorporate our print to make the initial drawings and also have the comfort of knowing that all of TEI’s processes are documented similar to their own processes.

TEI thanks Donna and all of our employees who “bought-in” to establishing the ISO system for our manufacturing. This system will continue to guide TEI’s growth in the future, enhancing customer satisfaction through continual improvement of this system.