Chapter 2 – Design Considerations

For a complete version of this document click here.

2-1. General

A dredging and dredged material disposal operation requires consideration of both short- and long-term management objectives. The primary short-term objective of a dredging project is to construct or maintain channels for existing navigation needs but not necessarily to authorized project dimensions. This should be accomplished using the most technically satisfactory, environmentally compatible, and economically feasible dredging and dredged material disposal procedures. Long-term objectives concern the management and operation of disposal areas to ensure their long-term use. This chapter out lines the design consideration usually needed to meet the objectives of a dredging project.

2-2. Preliminary Data Collection

In order to gather the data required for a dredging and dredged material disposal project, it is necessary to do the following:

a. Analyze dredging location and quantities to be dredged, considering future needs.

b. Determine the physical and chemical characteristics of the sediments.

c. Evaluate potential disposal alternatives.

d. Identify pertinent social, environmental, and institutional factors.

e. Evaluate dredge plant requirements.

2-3. Dredging Locations and Quantities

a. Dredging locations and the quantities of material to be dredged are two of the most important considerations in planning dredging projects. Since disposal of dredged material is usually the major dredging problem, it is essential that long-term projections be made for disposal requirements of each project. Records should be kept of quantities dredged and maintenance interval(s) to forecast future dredging and disposal requirements.

b. Hydrographic surveys are the principal dredged contract management tool of the Corps. Hydrographic surveys should be made prior to dredging to determine existing depths within the project area and after dredging to determine the depths that were attained as a result of the dredging operation. Each district should have the capability, either in-house or by contract, to make accurate, timely, and repeatable hydrographic surveys. To ensure accuracy, quantity calculations must be made from survey data gathered in a timely manner using proper equipment and based upon precisely established horizontal and vertical controls. Direct tide level readings must be made at the site of the work to eliminate gross errors in quantity calculations. Quantity measurement methods must be fully consistent between work performed by contract and work performed by hired labor.

2-4. Physical Properties of Sediments

In planning any dredging operation which constitutes a specialized problem in earthmoving or excavation, it is essential that field measurements and computations be made to determine the location, characteristics, and quantities of material to be removed. The characteristics of the dredged material determine dredge plant and, to some extent, disposal requirements. Refer to Chapter 4 for specific characterization tests required for evaluation and design of disposal alternatives for dredged material.

a. Sampling. Sediment samples should be taken of the material above the depth to which removal will be credited. This should be done concurrent with the pre-dredge survey. For maintenance dredging of a recurring nature, samples will be taken before each dredging until the characteristics of the sediments are well known. For subsequent dredging, a small number of samples will be taken to identify and changes in sediment characteristics. Normally the sediment sampling depth will be the authorized project depth plus an allowable tolerance (usually 2 ft) to compensate for the inherent inaccuracies of the dredging process. The number of sediment samples taken should be sufficient to obtain accurate information regarding the characteristics of the material to be dredged. Samples in soft materials can be obtained by push tube or grab samplers.

(1) Tube sampling.

(a) A tube sampler is an open-ended tube that is thrust vertically into the sediment deposit to the depth desired. The sampler is withdrawn from the deposit with the sample retained within the tube. Differences among tube samplers relate to tube size, tube wall thickness, type of penetrating nose, head design including valve, and type of driving force. Tube samplers (also called harpoon samplers) are available with adjustable weights in the range of from 17 to 77 lb and with fixed weights in excess of 90 lb. The amount of weight required depends upon deposit texture and required depth of penetration.

(b) The split barrel sample spoon (also known as split-spoon sampler) is capable of penetrating hard sediments, provided sufficient force is applied to the driving rods. The sampler is thrust into the deposit by the hammering force exerted on rods connected to the head. During retrieval, the sample is retained within the barrel by a flap. The nose and head are separated from the barrel in order to transfer the sample to a container. Refer to EM 1110-2-1907 for more information on soil sampling.

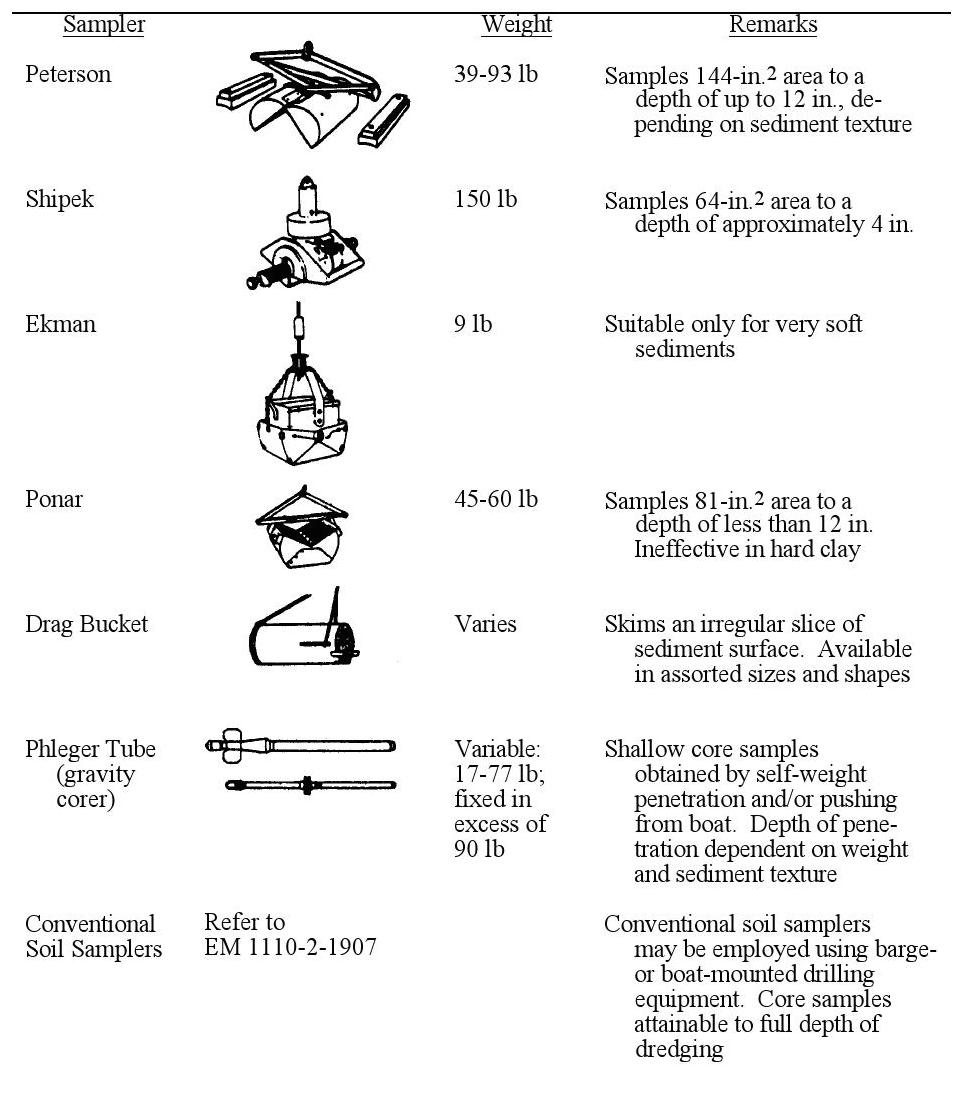

(2) Grab sampling. A grab sampler consists of a scoop or bucket container that bites into the soft sediment deposit and encloses the sample. Grab samplers are used primarily to sample surface materials, with depth of penetration being 12 in. or less. Crab samplers are easy and inexpensive to obtain and may be sufficient to characterize sediment for routine maintenance dredging. Crab sampling may indicate relatively homogeneous sediment composition, segregated pockets or coarse- and fine-grained sediment, and/or mixtures. If segregated pockets are present, samples should be taken at a sufficient number of locations in the channel to adequately define spatial variations in the sediment character and quantities of each material.

(3) New work. Samples taken by conventional boring techniques are normally required for new work dredging. Samples should be taken from within the major zones of spatial variation in sediment type or along the proposed channel center line at constant spacing to define stratification within the material to be dredged and to obtain representative samples. Borings are required for new projects and should be advanced below the depth of anticipated dredging. The relative density of sands can be determined by driving a split-spoon sampler and recording the number of blows required to penetrate each foot of sand. Refer to EM 1110-2-1907 for information on conventional soil sampling methods and standard split-spoon penetration tests. Information on the soil above and below the authorized new work depth is needed to properly design the channel slopes. It is essential to obtain the characteristics of the material to be dredged to preclude determination of unsuitable dredge plant, unrealistic production and cost estimates, etc. Pertinent information regarding sediment samplers is summarized in table 2-1.

b. Laboratory Testing. Laboratory tests are required to provide data for determining the proper dredge plant, evaluating and designing disposal alternatives, designing channel slopes and retention dikes, and estimating long-term storage capacity for confined disposal areas. The tests discussed below are to be used to characterize the material to be dredged so that a proper dredge plant can be selected. Specific tests for evaluation and design of disposal alternatives are discussed in Chapter 4. The required laboratory tests are essentially standard tests and generally follow procedures found in EM 1110-2-1906 . The extent of the testing program is project-dependent: fewer tests are required when dealing with a relatively homogeneous material and/or when data are available from previous tests and experience, as is frequently the case in maintenance dredging; for new work projects and unusual maintenance dredging projects where considerable variation in sediment properties is apparent from samples, more extensive laboratory testing programs are required. Laboratory tests should always be performed on representative sediment samples. Tests required on fine-grained sediments (those of which more than half pass through a No. 40 sieve) include natural water content, plasticity analyses (Atterberg limits), and specific gravity. The coarse-grained sediments (those of which more than half are retained on a No. 40 sieve) require only grain size analyses and in situ density determinations. These tests are described below.

(1) Natural water content test. Natural water content refers to the in situ water content of the sediment. It is used to determine the in situ void ratio and in situ density of fine-grained sediments. Water content determinations should be made on representative samples from borings and grab samples of fine-grained sediment obtained during field investigation. Fine-grained sediments do not drain rapidly; thus, representative samples taken from borings and grab samples are considered to represent in situ water contents. Detailed test procedures for determining the water content are found in Appendix I of EM 1110-2-1906.

(2) Plasticity analyses. Plasticity analyses (Atterberg limits) should be performed on the separated fine-grained fraction (passing the No. 40 sieve) of sediment samples. A detailed explanation of the tests required to evaluate the plasticity of sediments is presented in Appendix III of EM 1110-2-1906. Samples should be classified according to the Unified Soil Classification System (USCS) (item 12).

(3) Specific gravity test. Values for the specific gravities of solids in fine-grained sediments are required for determining void ratios and in situ densities. Procedures for conducting the specific gravity test are given in Appendix IV of EM 1110-2-1906.

(4) Grain size analyses. Grain size analyses are required only on the coarse-grained fraction of samples. Grain size analyses should follow the procedures contained in Appendix V of EM 1110-2-1906.

c. In situ density. In situ density is used to evaluate dredgability to sediments and aid in equipment selection, to estimate production rates, and to estimate volume required for storage in confined disposal areas. In situ density can be estimated from field investigations of sediments or from laboratory test data using geotechnical engineering formulas. Refer to Appendix II of EM 1110-2-1906 for guidance in estimating in situ density from laboratory tests. For sand sediments, relative density has a decisive influence on the selection of equipment for dredging. The relative density of sands can be estimated from standard split-spoon penetration tests (para 2-4a). Table 2-2 presents estimates of relative density of sands based on standard penetration tests. Where no field tests are performed on coarse-grained materials (i.e. sand, gravel, etc.,) the material in its densest state based on laboratory tests will be considered comparable to its in situ condition.

2-5. Selection of Dredging Equipment

Most Corps dredging is performed by private industry under contract, and the specifications should not be written such that competitive bidding is restricted. However, in certain situations limitations may be placed on the equipment to be used to minimize the environmental impact of the dredging and disposal operation. In cases where available upland containment areas are small, the size of the dredge should be restricted to minimize stress on the containment area dikes and to provide adequate retention time for sedimentation to minimize excessive suspended solids in the weir effluent. Environmental protection is adequate justification for carefully controlling the selection and use of dredging equipment. The dredging of contaminated sediments requires careful assessment of the dredging operation. The information presented in Chapters 3 and 4 will provide guidance for proper equipment selection based on the materials to be dredged, dredging environment, contamination level of sediments, transport and disposal requirements, and production requirements.

2-6. Disposal Alternatives

The major considerations in selecting disposal alternatives are the environmental impact and the economics of the disposal operation. Much of the recent knowledge concerning dredged material disposal was gained as a result of the Dredged Material Research Program (DMRP) conducted by the U.S. Army Engineer Waterways Experiment Station (WES) and reported in WES Technical Reports. The major objectives of the DMRP were to provide definitive information on the environmental impact of dredging and dredged material disposal operations and to develop new or improved dredged material disposal practices. The research was conducted on a national basis, excluding no major types of dredging activity or region or environmental setting. It produced methods for evaluating the physical, chemical, and biological impacts of a variety of disposal alternatives in water, on land, or in wetland areas, as well as tested, viable, cost-effective methods and guidelines for reducing the impacts of conventional disposal alternatives. Summary reports produced under this program are listed in para 1-3, and a detailed discussion of disposal alternatives is presented in Chapter 4. Two fundamental conclusions were drawn from the results of the DMRP concerning disposal of dredged material:

(1) no single disposal alternative can be presumed most suitable for a region, a type of dredged material, or a group of projects before it has been tested, and (2) environmental considerations make necessary long-range regional planning for lasting, effective solutions to disposal concerns. There is no inherent effect or characteristic of a disposal alternative that can rule it out of consideration from an environmental standpoint before specific on-site evaluation. This holds true for open-water disposal, confined upland disposal, habitat development, or any other alternative. Case-by-Case project evaluations are time-consuming and expensive and may seriously complicate advanced planning and funding requests. Nevertheless, from a technical point of view, situations can be envisioned where tens of millions of dollars may have been or could be spent for disposal alternatives that contribute to adverse environmental effects rather than reduce them. Also, easily obtained beneficial impacts should not be overlooked. No category of disposal alternative is without environmental risk or offers the soundest environmental protection or reflects the best management practice; therefore, all disposal alternatives should be fully investigated during the planning process and treated on an equal basis until a final decision can be made based on all available facts. It is hypothesized that all alternatives could be considered to dispose of even the most highly contaminated dredged material if a plan could be devised for management that was adequate and legally acceptable under domestic regulations and international treaty.

2-7. Long-Range Studies

Dredging and disposal activities cannot be…

-

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99

SPW911 Sheet Pile Design Software

Rated 5.00 out of 5$150.00 – $599.99Price range: $150.00 through $599.99 -

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00

Sheet Pile Design (PDF Download)

Rated 5.00 out of 5$89.00 -

Pile Driving (PDF Download)

$89.00

Pile Driving (PDF Download)

$89.00

-

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

Marine Construction Volumes 1 & 2 (PDF Download)

$157.00

-

Pile Driving (Book)

$89.00

Pile Driving (Book)

$89.00