INTERVIEW: Cajun Industries

Pile Buck’s interview with Cajun Industries, LLC, the trusted contractor of industrial and commercial clients throughout the U.S. and internationally.

PB: Tell us about The Cajun Company.

C: Cajun Industries, LLC was founded in 1973 as a merit shop company specializing in structural concrete. Cajun has spent decades honing its competency in civil, deep foundations and mechanical services. As the company has grown, so has its core competencies. Today, we are a nationally recognized construction leader providing fully integrated self-performed EPC (Engineering, Procurement and Construction) services to some of the largest and most renowned companies in the world.

PB: What are Cajun’s core competencies?

C: Our core competencies include multi-discipline engineering, civil, structural and mechanical work coupled with specialized expertise in deep foundations, marine and pipe fabrication. Our civil division provides demolition, site work, underground piping, paving and structural concrete. Our mechanical division specializes in process piping installation, equipment installation and alignment, and structural steel. Our deep foundations division has expertise in pile driving, drilled shafts, helical piles, auger piles, and drilled displacement piles. Also, within our core competencies is piping fabrication and erection, with ASME stamps. While our marine division brings specialization in marine and dock construction and shore stabilization.

PB: What markets does Cajun serve?

C: Cajun provides a broad range of services to various markets including oil, gas and energy; chemical processing; refining; power; manufacturing and buildings; governmental infrastructure; alternative energy; emergency and disaster response; communication; water quality; and more.

PB: What size projects does Cajun accept?

C: Our projects can range from a few hours of consulting to comprehensive front-end engineering and detailed design, as well as complete EPC portfolio management. We offer flexibility and fit-for-purpose execution for all sizes of jobs.

PB: How does Cajun handle large, complex projects?

C: Cajun has a strong team of superintendents who specialize in project execution and are supported by a project management staff that has a wealth of experience on large projects. We grow our people to grow our company.

PB: Do you provide equipment for projects?

C: Our team is supported by a large fleet of company-owned equipment and qualified operators. Cajun can provide all services on a lump sum, cost-reimbursable, unit-rate, and/or fixed-fee basis.

PB: Can Cajun help clients find staffing?

C: We specialize in on-site staffing through our technical services program and offer globally integrated project delivery. Cajun is ready to deliver exceptionally talented project teams.

PB: Does Cajun offer deep foundations services?

C: Cajun designs and self-performs a wide range of deep foundation disciplines on both land and water throughout the U.S. and internationally. We have a company-owned fleet of specialized equipment that enables us to efficiently produce safe, high quality, and economical deep foundation systems ranging in size from small single-pile to large mega pile.

PB: Do you offer pipe fabrication?

C: Cajun operates a state-of-the-art facility adjacent to I-10 with waterway access for modular fabrication. We are experienced in a wide array of metallurgy options: carbon, stainless and high alloys with over 100 qualified welding procedures. In addition, we maintain AMSE code stamps A, U, and PP, and NBIC code stamp R.

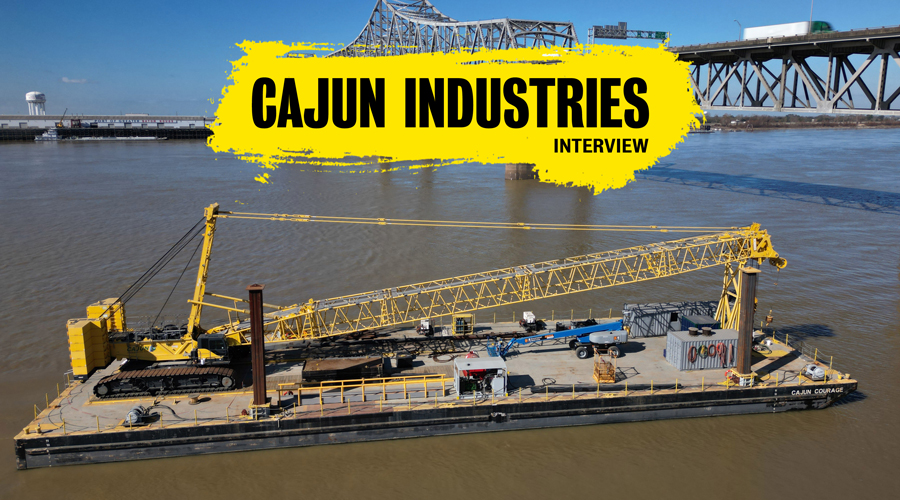

PB: Tell us about your marine construction services.

C: Cajun services and constructs numerous types of projects ranging from the lower Mississippi River and its tributaries, to coastal and offshore waters. We specialize in marine projects that demand intensive planning and constructibility reviews, and intricate construction.

PB: What are some of your marine capabilities

C: Some of our marine capabilities include design/build; construction; construction management; Early Phase (FEED) Constructibility; docks – ship, barge, heavy haul, bulkhead and loading arms; dolphins; dredging; pile driving; structural steel; intake; outfall; flumes; heavy lifts; barge transportations; open cell; and bridge construction.

PB: Why choose Cajun for marine construction projects?

C: We are rooted in safety and feature company-owned equipment including ocean-class barges that allow us to operate safely and in compliance with regulations when working outside of the line of demarcation. We deliver both design-build and bid-build marine projects for a wide range of clients in various industry sectors. Cajun also has a construction support facility, Westport, in Port Allen, Louisiana. This allows easy access to I-10 and the Mississippi River. The facility has over 56,000 SF of covered work area, 70-ton total crane capacity, 57.5 acres stabilized, temporary laydown, storage and office space.

PB: Tell us about the ExxonMobil Dock 5 Project.

C: Cajun self-performed EPC services including detail design engineering and procurement for the Dock 5 hose tower structure. The facility included (3) 10” diameter, boom supported, marine loading arms for diesel export.

PB: What was Cajun’s scope of work for that project?

C: Cajun’s scope of work included pipe pile foundations, process piping, structural steel, equipment and E&I. Cajun utilized AWP in the execution of this project. There were no weld rejections or non-conformance reports (NCR) with ExxonMobil. In fact, the project won the ABC Eagle Award Winning Project.

PB: How long did the project take?

C: The project was an 11-month duration, and was completed within a week of the estimated 12-month schedule.

PB: What’s another successful Cajun marine construction project?

C: Another marine project that Cajun completed successfully was the United States Army Corp of Engineers – New Orleans District WBV – 16.2 Bayou Segnette Complex Project in Jefferson, Louisiana. This project involved enclosing the Company Canal to allow it to serve as a safe harbor during storm events and to provide a new line of hurricane protection to 100-year storm levels.

PB: What was Cajun’s scope of work for this project?

C: Cajun’s scope of work included construction of a new sector gate and pump station together with their associated channels, construction of a T-wall type floodwall, and construction of a channel closure across Bayou Segnette. Also included in the scope of work was construction of a permanent section of earthen levee from the sector gate to the adjacent floodwall.

PB: Sounds like a pretty major marine construction project.

C: It definitely was. We placed approximately 10,000 CY of reinforced concrete; channel excavation (dredging) of approximately 75,000 CY (including one navigable channel for the sector gate); embankment of approximately 58,000 CY of compacted fill for the construction of an 14’ earthen levee; installed over 42,000 SF of sheet piles; installed a treated timber pile finder system; installed 24” and 30” pipe piles; constructed a guide wall using a floating plant; installed needles, a needle girder and a storage platform; placed over 33,000 tons of 650LB rip rap from a barge; installed scour protection, operating machinery at the sector gate and pump station, water craft protection dolphins in Company Canal and at pump station; and designed and implemented emergency gap closure and temporary flood protection plans to replace existing protection that was removed for construction access tie-ins with new protection.

PB: Tell us about your newest edition to the Cajun Marine Business Unit, the Cajun Freedom.

C: We recently have finished construction and introduced the Cajun Freedom to our fleet of barges. The Cajun Freedom is 270’x72’16’ Class Powered Spud Barge with a Lampson 4100 Series 3 Ringer Crane. We are excited about the new opportunities we will accomplish with the Cajun Freedom.

PB: What else do you want our readers to know about Cajun?

C: Ultimately, partnering with Cajun ensures a world-class project delivery experience with predictable results highlighted by our proven leadership and management processes, quality execution, and an unparalleled commitment to safety.