Ferry Terminals and Small Craft Berthing Facilities – Manual Part 1

View the complete article here.

Constructing a ferry terminal or a small craft berthing facility requires a thorough understanding of not only how to build a project in, or alongside a wet environment, but also of navigational basics, the environment, weather patterns, and how tides, waves and other factors will impact the project.

There are numerous considerations that must be taken into account in designing and planning a ferry terminal or small craft berthing facility.

From the initial conceptualization through the final construction of the project, the utmost care must be taken to ensure that the facility is built to withstand the elements. By evaluating the intended use of the facility along with the environment in which it is being built, the construction project can be a success.

Ferry Terminals

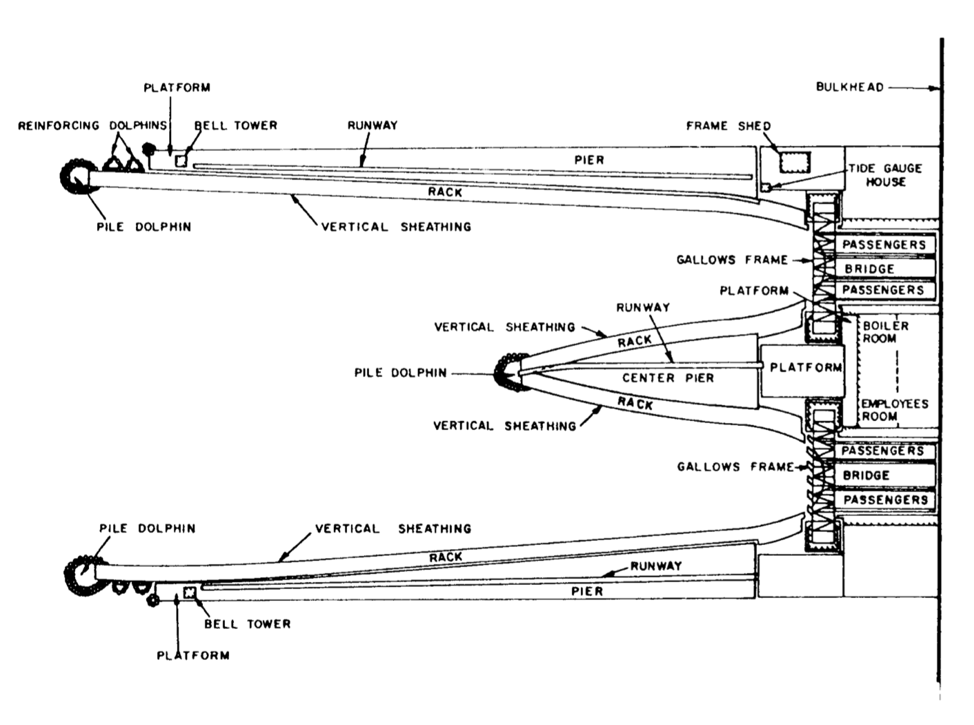

Constructing ferry terminals requires an understanding of the main components of these facilities: slips and fender racks.

Slips consist of water areas located directly in front of transfer bridges. They are typically bordered by fender racks. These racks generally diverge offshore, with inshore ends fitting the end contours of ferry boats.

The width of the offshore openings of fender racks will be determined by the type and size of vessels that will be accommodated at the slip, as well as the site location. The top of the fender racks must be high enough to enclose the guard rails of the ferries at high, high water (maximum elevation). The depth of the water required for a slip will depend on the ferry that must be accommodated.

Fender racks should be designed to deflect approaching ferries towards the transfer bridge. Generally, fender rack piles should be connected by heavy, longitudinal timbers so that impacts from a vessel are distributed along the length of an entire rack.

Dolphin clusters should be provided at the offshore ends of racks. If more than one row of piles is used in a rack, the rear rows should be staggered from the forward ones, and, if necessary, cut off at lower elevations.

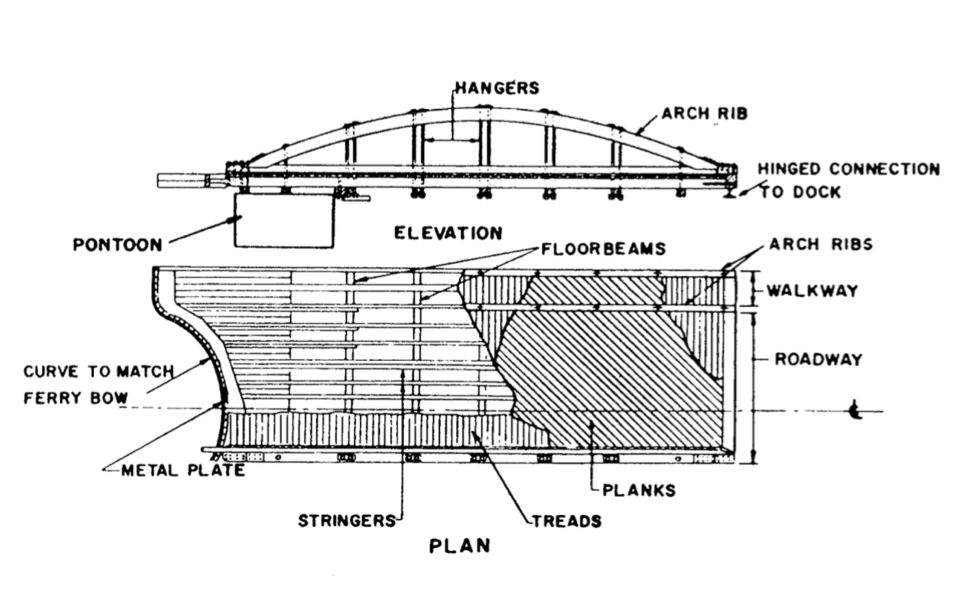

Ferry transfer bridges provide lengths that are sufficient to hold ramp slopes within practical limits during extreme tides and drafts. For example, a ferry transfer bridge may allow truck and passenger vehicles to be held at 10 percent during tides and drafts.

Contractors should curve the offshore lines of these bridges to fit the ends of accommodated ferry boats. Bridge ends are adjusted for height by hand- or power-operated winches.

The inshore end of a bridge must be supported by rollers, hinged rollers or sliding bearings, and should bear longitudinally against spring or rubber buffers to absorb the shock of incoming boats.

The offshore end of a ramp should be fitted with iron brackets, hardwood or toggles, which may bear on the deck of a ferry boat. To relieve the loads on operating machinery, counterweights should be used.

Finally, contractors should provide ferry transfer bridges with winches so that slacks can be taken up in mooring lines from ferries to the bridges.

Small Craft Berthing Facilities

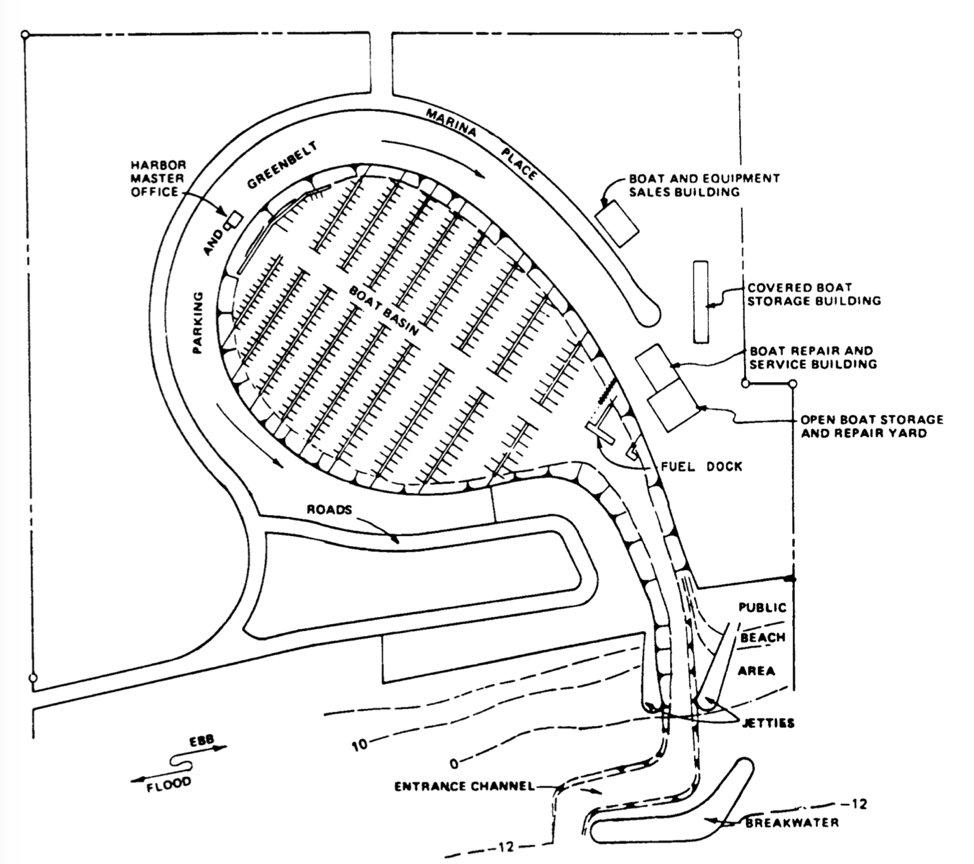

When designing a small craft berthing facility, contractors should carefully design the project to meet plan and layout criteria. Doing so will ensure that the facility can be put to its best use, and that small crafts that use the berthing facilities can do so safely and without damage.

In designing the facility, due to different land use requirements it is best to provide separate areas for commercial and recreational craft.

As a general rule, larger crafts should be berthed near the entrance of the facility. Also, commercial boats should be located near the entrance, either across a fairway from recreational crafts or in a separate basin.

If a berthing facility will hold sailboats without auxiliary power, there should be slips that are open to the leeway of the prevailing winds that can be reached through wide fairways and channels, or via routes that allow for sailboat tacking with the least amount of interference to powered craft.

Other considerations for the design and layout of small craft berthing facilities include locating, as far away from the berthing areas as possible, the ramps and hoists for launching small crafts from trailers.

Operational dry storage facilities should be located as far away from the berthing areas as possible, with launching and retrievals accomplished by hoist instead of by ramps. Similarly, boat repair and servicing cars should be located in a remote part of the harbor that nonetheless has proper navigation access for the largest craft served by the facility.

On the other hand, boat-fueling docks should be located near the entrance to the facility in a place that is protected from the waves. The land that is next to the boat-fueling area must be suitable for buried fuel storage tanks, as well as readily accessible for vehicles that will distribute fuel.

Generally, a pump-out station will be located in the same location, on or along the fueling dock.

Finally, a harbor administration area should be located near the entrance and guest docks, along with vehicle parking for the berthing basins. Ideally, no parking space in any parking lot should exceed 500 feet from the head of the pier that it serves.

Planning the construction of a small craft berthing facility requires full consideration of the proposed project site and the boats it will serve so the facility is carefully situated. A carefully-planned design will ensure that all boats can properly navigate the harbor and utilize the facility. It also will enable the facility to be used to its highest capacity potential.

FIRST, contractors should consider the berthing basins. Good basin geometry requires adequate clearances for slopes beyond the beam and length of the craft width; entrance and exit channels; and the depth and width of water area for maneuvering to and from slips. This will allow water crafts to safely maneuver and navigate.

An average harbor with all-ship moorage where good basin geometry can be obtained will be able to berth between 15 and 20 boats (30 to 35 feet in length) for every acre of navigable water area, which includes the main interior channel, slip areas and fairways.

The depth of the berthing basin also must be evaluated. The depth of the berthing basin should be at least two feet below the keep of the deepest-draft boat at extreme low water.

SECOND, contractors should secure adequate land to serve both the harbor and berthing facility. Typically, land area will be about 80 percent of the water area. This is roughly the equivalent of 160-square meters per boat.

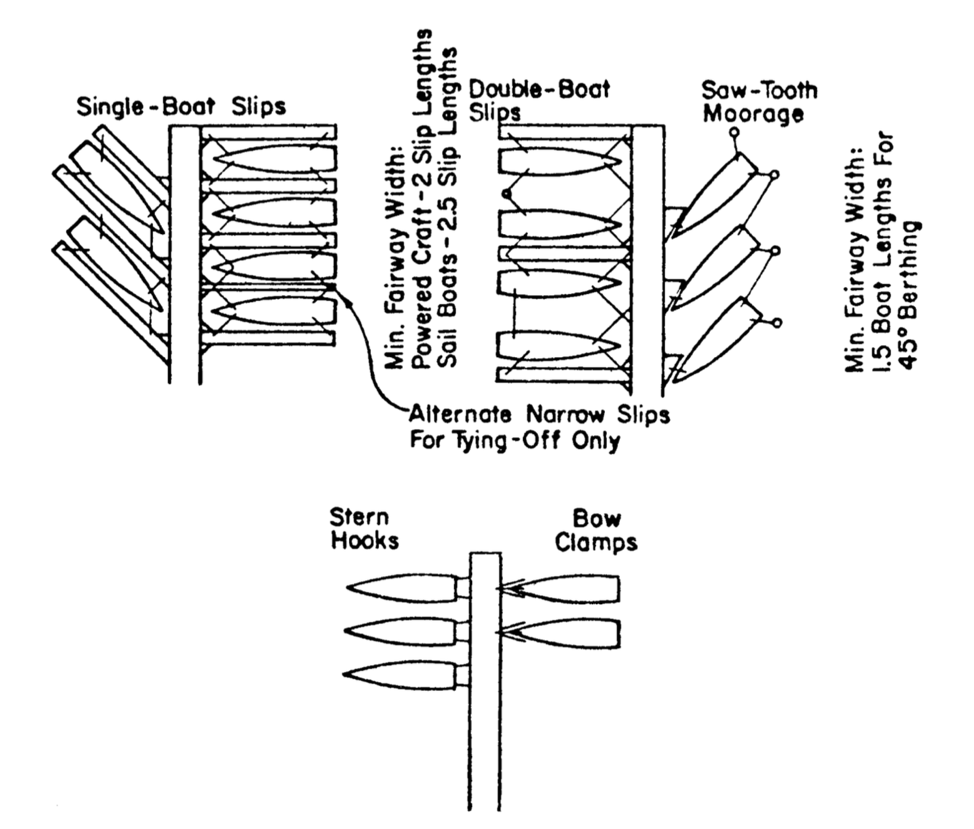

THIRD, the size of each slip should be calculated. Two-boat slips require wider fingers than single-boat slips. For this reason, they will take up approximately the same area as single-boat slips.

If bow and stern moorings are used in place of slips, approximately two to four times as much water area is required, depending on water depth.

If the facility is providing full-circle clearance for the crafts, single-point moorings require about six times the area as bow and stern moorings.

FOURTH, other amenities should be factored into the overall plan. These include launching ramps, which will launch and retrieve an average of 50 trailered boats on a high-traffic day.

A parking lot should have a minimum of three spaces for every four boats in the berthing area.

Finally, harbor service facilities should have a land area that is approximately equal to the parking area.

FIFTH, the channel should be aligned as closely with the natural channel alignment as possible.

The waterside approach should be as wide as possible to allow for simultaneous entrance and exit of the widest boats that are anticipated to use the facility.

If the entrance is aligned with the main channel, the minimum width should be no less than 150 feet. If the boat must make an immediate turn inside of the basin, the channel should be at least 250-feet wide.

Protections for the channel, such as jetties, breakwaters, or groins, should be provided also to prevent littoral drift and protection from waves.

Environmental Siting Factors

Contractors must also evaluate the various environmental factors that may impact a potential berthing facility. There are numerous issues that should be considered when planning a site, as each may affect the facility’s operation.

Amount and Type of Precipitation

One important factor is the amount and type of precipitation that a proposed area receives. The site should be fitted with adequate surface draining that will allow water from maximum probable rainfall to be drained without eroding perimeter land.

In addition, the drainage should allow any possible inflows from surrounding land to be diverted safely through the harbor complex. If necessary, covered slips should be provided to keep boats dry above the waterline, to shed snow, prevent hailstone damage, and to protect boats from too much exposure to sunlight.

In areas where there is heavy snowfall, contractors should design landslide structures and slips to carry a heavy snow load or, alternatively, to shed snow.

Wind Damage

To protect against wind damage, contractors should work with specialists to determine the most severe wind conditions that might occur at the berthing facility site using historical meteoritical records.

Floating slips should be designed to withstand the horizontal thrust of the berthed crafts during adverse wind conditions.

Finally, suitable anchorage should be provided for the slips to prevent both the boats and the harbor complex from drifting under heavy winds.

Ice Conditions

For locations that may be susceptible to ice conditions, contractors should take precautions to prevent damage due to ice.

Boat removal (either to dry storage or above the water) should be specified as a precaution against sheet-ice damage to boats.

The small craft berthing facility can be designed to minimize damage from the formation of sheet ice and drifting ice floes. This may include the use of deeply-driven steel or metal-clad timber piles, which will allow the ice to slide along the piles as it passes, or using floating slips with tapering or road bottoms, so that the ice will squeeze them upward as it contracts.

Smooth concrete lining can prevent erosion of basin perimeters and revetted slopes, while deflecting booms of logs or heavy timbers can be used to protect the berthing area from drifting ice.

If fog is an issue in a particular locale, the entrance channel and the main fairways to the berthing facility should be as straight as possible. In addition, marker buoys and other channel marking devices should be used to make the lanes as safe to navigate as possible.

Waves and Tides

Other environmental factors to consider include those related to waves and tides. For example, contractors must consider the wave action from the entrance channel and interior basins.

To reduce the swell from these areas to acceptable heights, the orientation of the entrance channel, protective breakwaters and jetties and interior wave-dissipating devices should be appropriately planned and selected.

This can be done using historical wave data and statistical hind-cast data. If a small craft harbor opens into an ocean or large lake, the entrance should be oriented for a boat to enter without turning broadside to incoming waves.

Surge

Contractors should take surge into consideration when planning a small craft berthing facility. Surge oscillations in a basin can cause stress in mooring lines as well as in anchorage systems. They can also make maneuvering boats into slips difficult.

For these reasons, vertical basin walls are generally better than basin perimeters. Note: rectangular basins are more efficient than irregular-shaped basins.

Shoaling

The entrance to a berthing facility may become progressively more shallow due to a process known as shoaling. There are multiple factors that may cause this, including littoral drift, which is the longshore movement of sand, primarily due to wave action.

To minimize shoaling along the entrance channel, contractors can install jetties along each flank from the mouth seaward beyond the breaker zone. These jetties should be designed to prevent the materials from washing through or over them into the channel.

Another cause of shoaling is river discharge, or sediment discharge which is created by the entrance configuration and the flowing water in the river.

To minimize river discharge, contractors can provide a flat area on the downstream lip of the entrance. From this flat area, a dragline can excavate deposits from the bottom of the entrance channel and cast these deposits into the river downstream from the entrance.

Other causes of entrance shoaling may include nearby water area structures, and redistribution of bottom materials.

Other Environmental Factors

Other environmental factors that should be assessed prior to beginning construction of a small craft berthing facility include the characteristics of the subsurface below the midline prior to excavation. This will aid in the determination of the best method of removal.

Geotechnical data can be obtained through exploratory borings so that the holding resistance of guide piles, probable lengths of piling for bulkheads, cofferdams and structural foundations and retaining walls can be evaluated.

Designing a Berthing System

One of the main decisions to be made in planning a small craft berthing facility is choosing between a fixed or floating pier system. Each has its own advantages, with the decision largely dependent on price, tidal range, safety and convenience. For some facilities, a combination of both fixed and floating piers is the best option.

Fixed piers:

- slightly less expensive to construct

- less costly to maintain

- stronger, more durable and more stable

- bear heavier loadings

- withstand impacts more readily than floating piers

- maintain a constancy of level between the pier and water

- allow for a rearrangement of layout

- no need to adjust mooring lines

- less likelihood of damage to boats under tidal conditions

As a general rule, fixed piers are appropriate for harbor basins where water surface levels do not fluctuate more than two feet and the water depth is 20 feet or less.

However, if water surface levels fluctuate five feet or more, floating piers should be used.

The type approach pier and gangway used will depend on whether the pier is fixed or floating.

- For fixed berthing systems, fixed piers should be utilized.

- For floating piers, hinged gateways should be used.

Fixed piers are an extension of the headwall to a landing on either the bulkhead or an abutment at the shoulder of a sloping bank.

On a floating pier, one end of the gangway is supported by floats. The gangway should be lightweight, and only long enough to slope at a predetermined maximum level at an extreme low water level.

Gangways should have handrails, and be hinged at the top inside edge of a perimeter bulkhead wall.

Designing Sheltered Basins Structures

In addition to ensuring that the berthing facility itself is stable, consideration must be given to the structures that form the harbor itself. These include the perimeter, beach, slope, and bulkhead. Carefully designing each element is vital to make sure that the overall facility is structurally sound and functions as necessary.

As an initial matter, contractors should work to stabilize the perimeter of the harbor basin. This should be done to retain the perimeter material, or to hold it on a given slope against forces that may cause sloughing or piping under a wall or through a revetment.

Stabilization should also be done to prevent damage to the perimeter by external forces, such as wave action, currents, or impact by floating objects that might erode or damage the slope or perimeter wall.

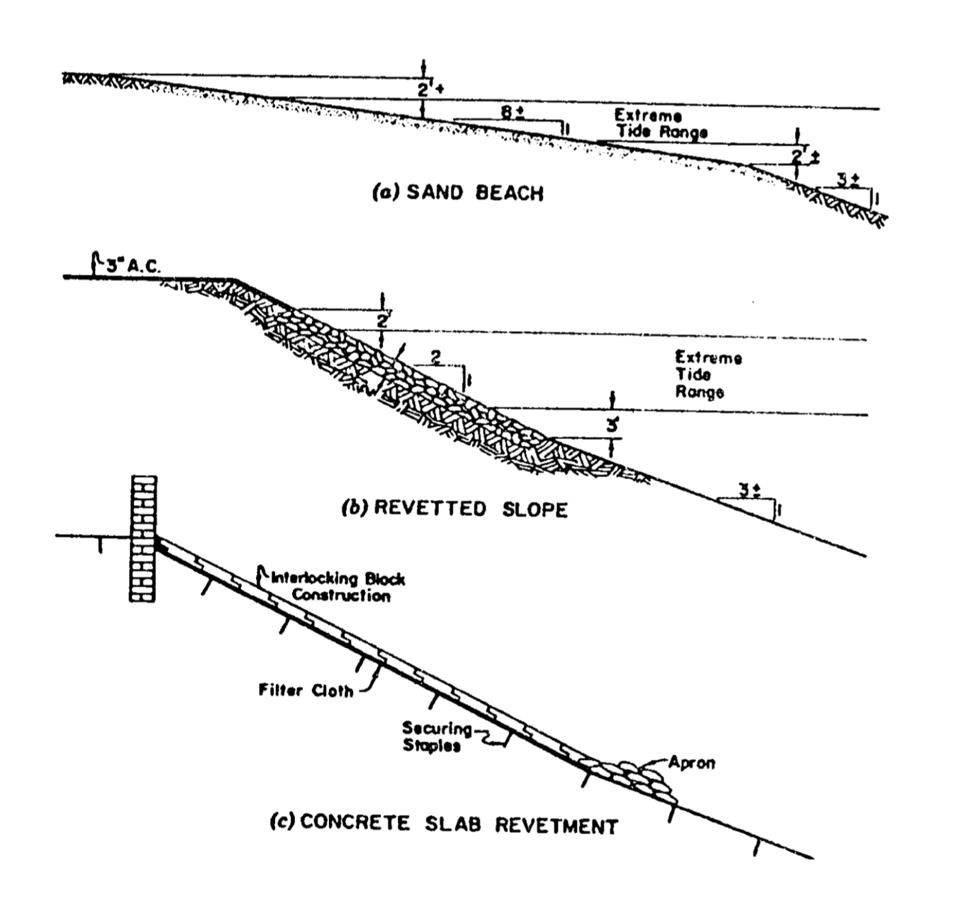

To accomplish these goals, the perimeter should be designed with the appropriate structures, which may include a perimeter beach, a revetted slope, a gabioned slope, or a vertical bulkhead.

A perimeter beach can be made of sand, gravel, pebbles or similar rock fragments. Depending on the material uses, the slope may be steep, as the littoral transport process will be too weak to cause any lateral displacement of larger materials.

Revetted slopes may be required where bank conditions require armoring the slopes. Contractors can provide a revetment of stone layer or precast concrete slabs placed on a filter course of spalls or gravel or tough, continuous synthetic cloth.

Contractors can determine the minimum stone size of a riprap or revetted slope based on the maximum wave action and currents.

Gabioned slopes are used where adequate small-size stones are available. These rock-filled, wire-mesh gabions allow installation of steep slopes for perimeter stabilization at a relatively low expense.

Vertical bulkheads can be used to reflect waves. They should generally be avoided where surge and wave penetration into the basin interior cannot be avoided.

Cast-in-place concrete bulkhead construction can be used if the site can be dewatered; otherwise, sheet piling bulkhead can be used. The bulkhead is usually only carried to the low water elevation, with the underwater slop extending from the base of the bulkhead wall down to the design depth.

View the complete article here.

What are the main considerations when designing a ferry terminal or small craft berthing facility?

Key considerations include slips, fender racks, water depths, and environmental factors like tides, waves, and weather patterns.

How should contractors decide between fixed and floating piers when planning a small craft berthing facility?

Generally, use fixed piers in areas with water surface fluctuations up to two feet; for fluctuations of five feet or more, floating piers are more suitable.